Master Your Plumbing: Earl's Performance Flaring Tools

Looking for the perfect flare? We review Earl's Performance Flaring Tool, including its capabilities for stainless steel, double flares, and more.

This site contains affiliate links, and we may earn a commission at no extra cost to you. All recommended products are thoroughly vetted.

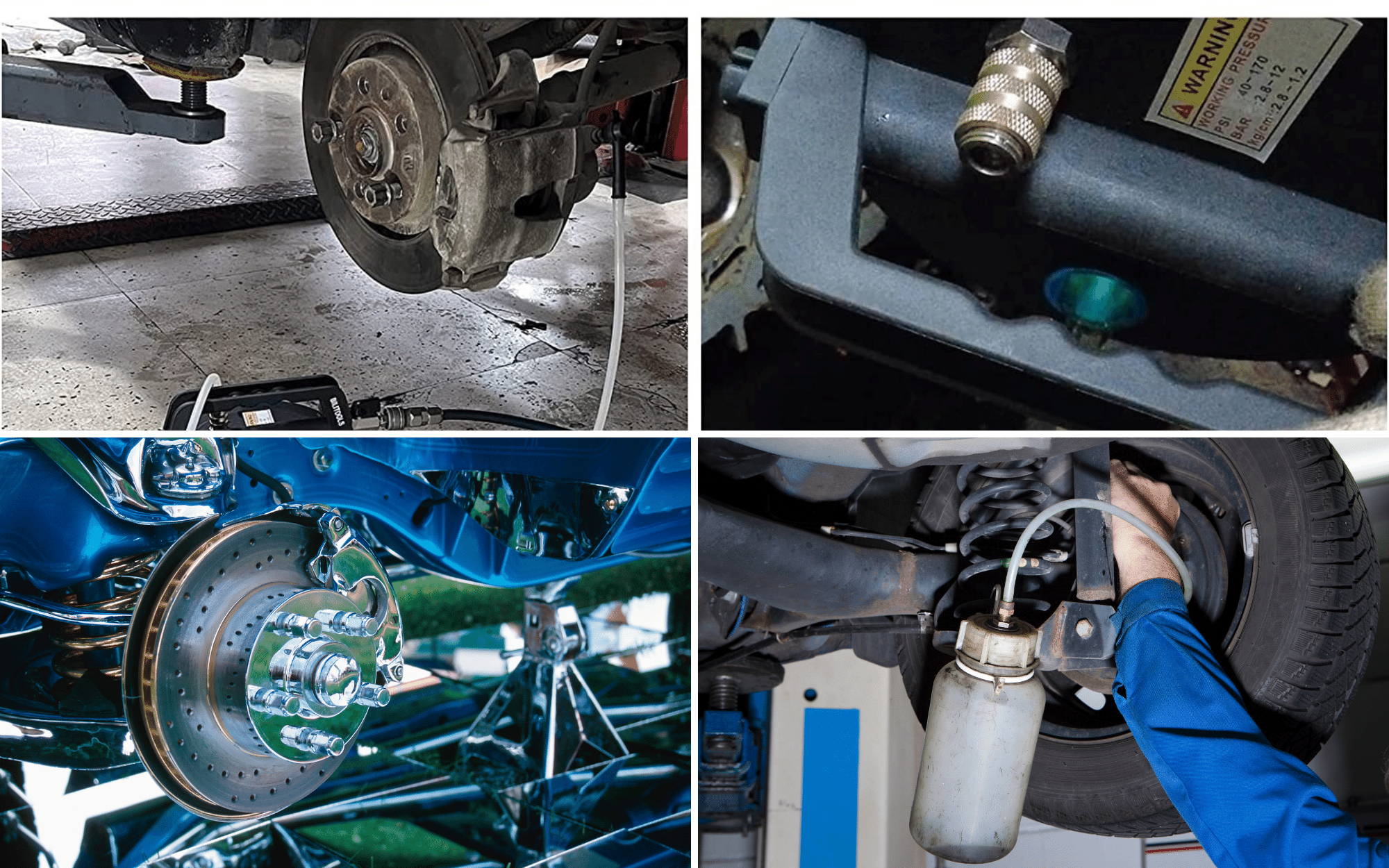

You can have the most powerful engine block on the market and the stickiest tires on the track, but if your plumbing fails, you aren’t going anywhere. For professional mechanics and dedicated automotive enthusiasts, the difference between a leak-free system and a dangerous failure often comes down to the quality of the flare.

Cheap tools chew up tubing and create uneven seals. Professional results require professional equipment. Enter the Earl’s Performance Flaring Tool 001ERL. Earl's flaring tools are known for their high quality, precision, and reliability, making them ideal for professional use. Earl's Performance flaring tools are designed for professional use and made from forged, hardened steel components, ensuring long-lasting durability.

The Cam & Lever design of Earl's flaring tools provides a fast, easy way to operate. Whether you are plumbing a brake system or installing a fuel line, this kit offers the versatility and durability required for high-performance applications. Earl's Performance flaring tools work on all tubing materials, including stainless steel, copper, steel, and aluminum.

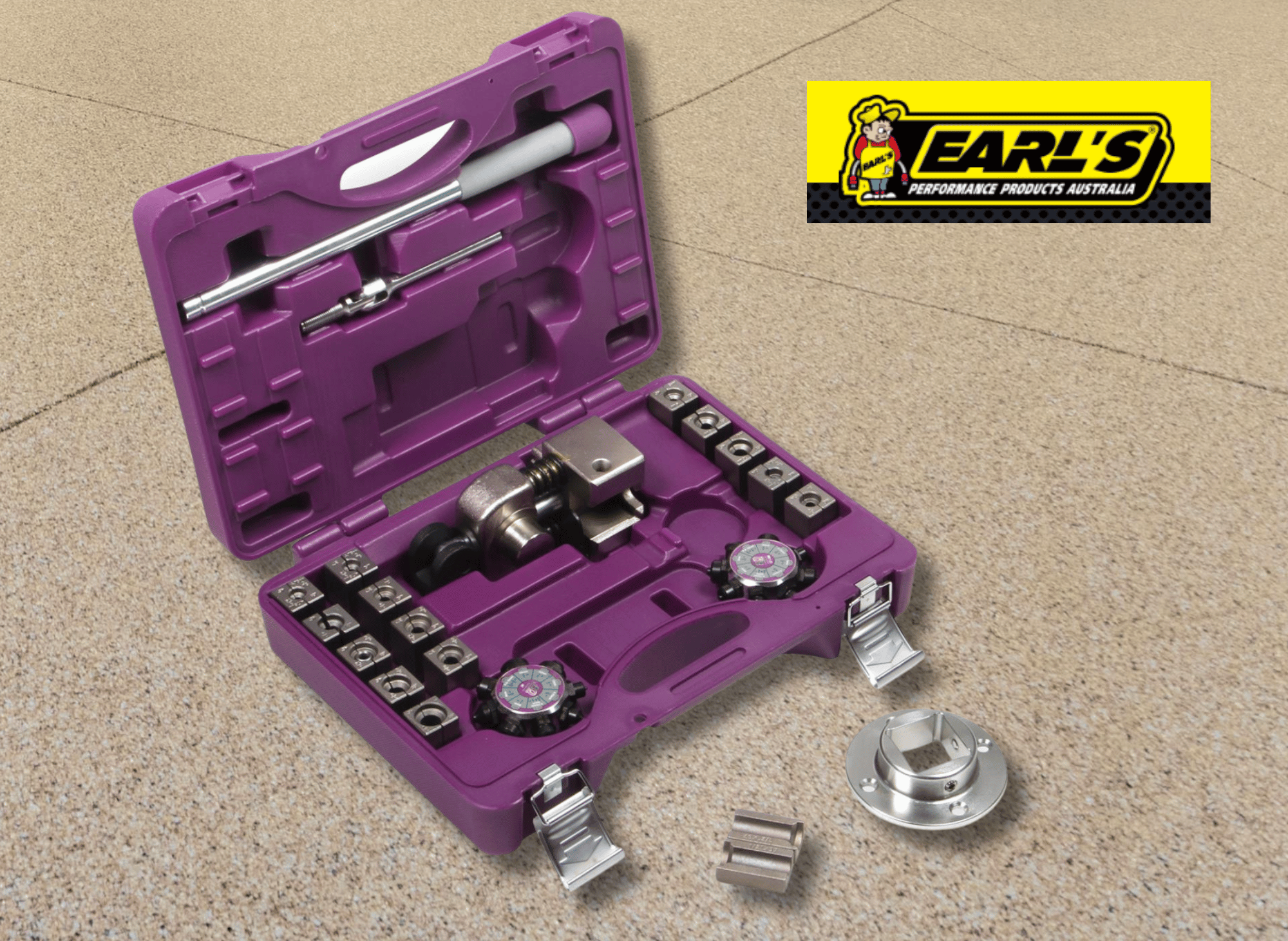

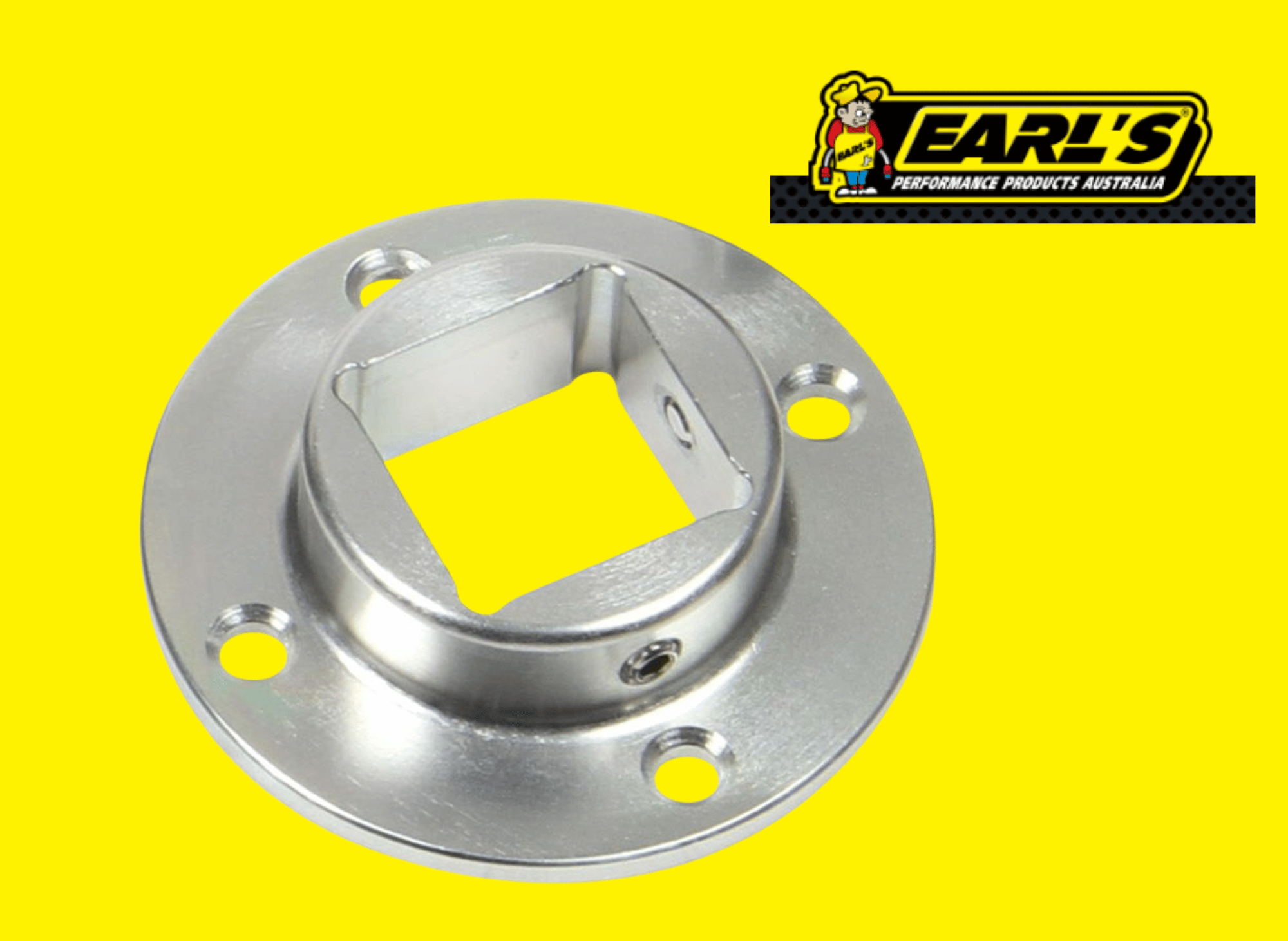

Earl's Performance Flaring Tools 001ERL

Flaring Tools, 37/45 degree, Single/Double/Bubble Flare, Kit

Versatility for Every Build

The features of Earl's Performance Flaring Tool include exceptional versatility, durability, and reliability, making it a top choice for automotive professionals and enthusiasts.

One of the biggest frustrations in an auto shop is needing a different tool for every specific job. The Earl’s Performance Flaring Tool addresses this by offering exceptional versatility in a single package. It is engineered to handle a wide variety of flare types, ensuring that whatever your project demands, you have the capability to execute it.

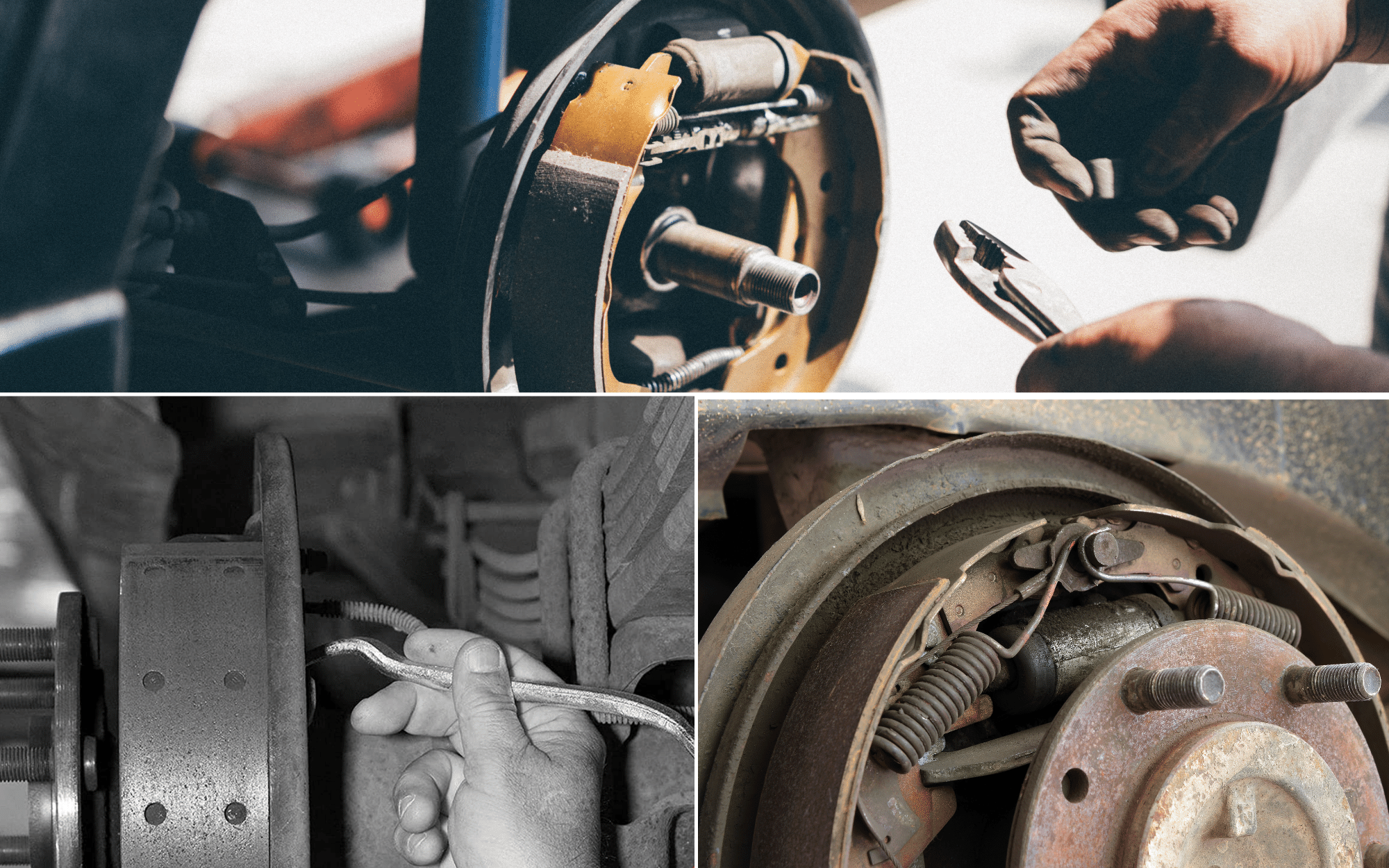

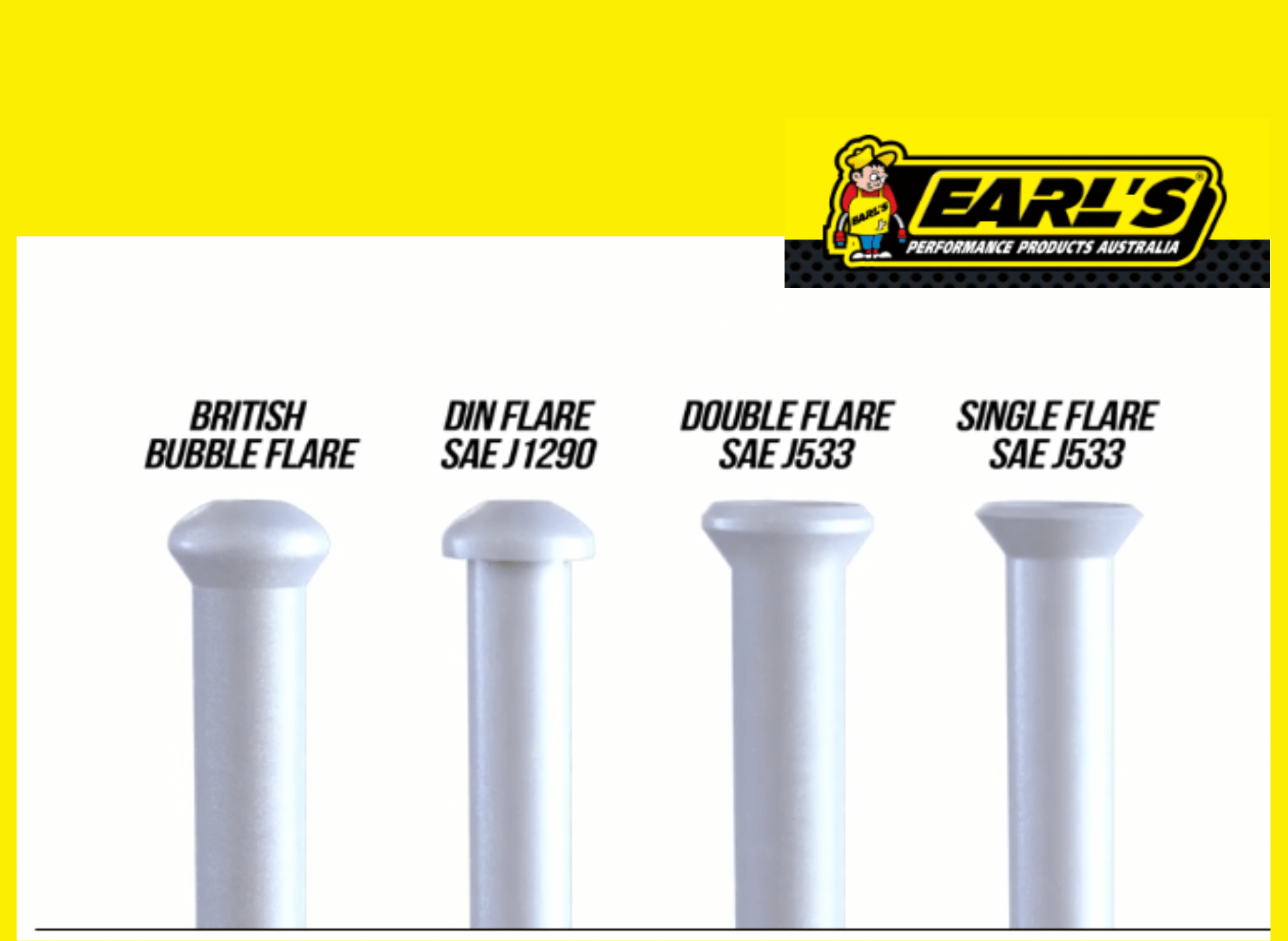

The kit is designed to create precise 37-degree, 45-degree, and DIN flares. Earl's flaring tools can create 37°, 45°, and DIN flares, providing flexibility for various applications. This dual capability is crucial because while 45-degree flares are common in standard automotive brake lines, 37-degree flares (often associated with AN fittings) are the standard for high-performance and racing applications.

Furthermore, the tool adeptly handles single, double, and bubble flares (DIN flares). This means you can switch from working on a vintage American muscle car to a modern European import without needing to purchase a separate set of tools. Don't struggle with things anymore!

These tools are used for fabricating and repairing high-performance automotive plumbing, including brake lines and fuel lines.

Material Compatibility: No Tube Too Tough

Most generic flaring tools work well on soft copper but fail when used on harder metals. They tend to slip, mar the surface, or break entirely. Earl's professional flaring tool distinguishes itself through superior material compatibility.

This system is robust enough to form clean, consistent flares on:

- Stainless Steel: Notorious for being difficult to flare due to its hardness, yet essential for high-end, corrosion-resistant lines.

- Copper: Soft and easy to work with, but requires a gentle touch to avoid thinning the metal too much.

- Aluminum: Lightweight and popular in racing, but prone to cracking if the tool isn't precise.

- Mild Steel: The standard for general automotive repair.

By effectively managing this range of materials, the 001ERL ensures that you can select the best tubing for your specific performance needs without worrying if your tool is up to the task.

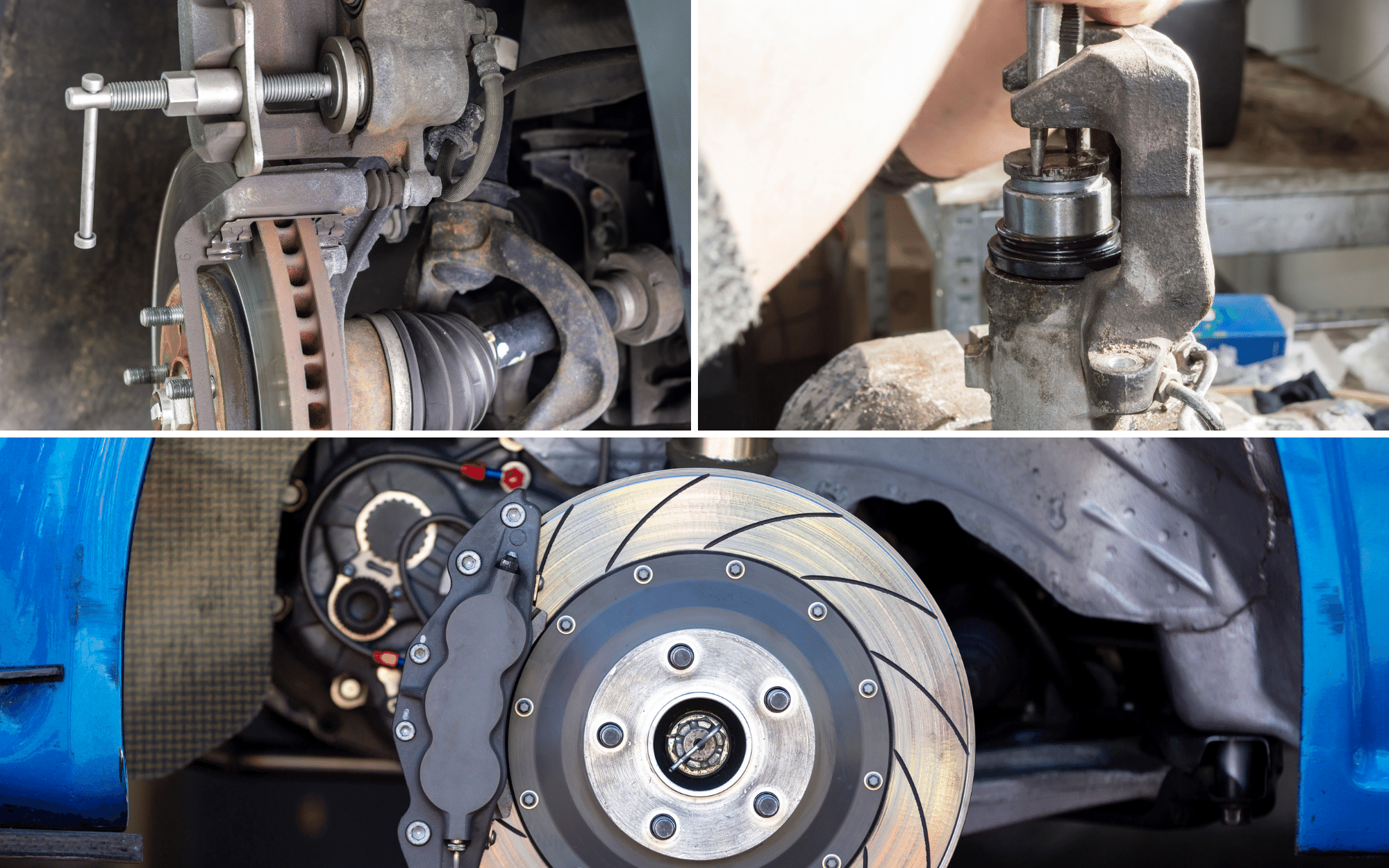

Built to Last: Hardened Steel Components

When you invest in shop equipment, you expect it to last. The build quality of Earl's Performance Flaring Tools is immediately apparent. The critical components are manufactured from forged and hardened steel. This construction isn't just about longevity; it's about consistency.

Soft tools flex under pressure, leading to off-center flares and poor sealing surfaces. The rigidity of the forged turret and punches in this kit ensures that all force is directed into forming the metal rather than deforming the tool.

This design securely holds the tubing without pinching or leaving unsightly marks on the back of the flare, a common issue with lower-end clamp-style tools. When you simply need the job done right the first time, this durability is invaluable.

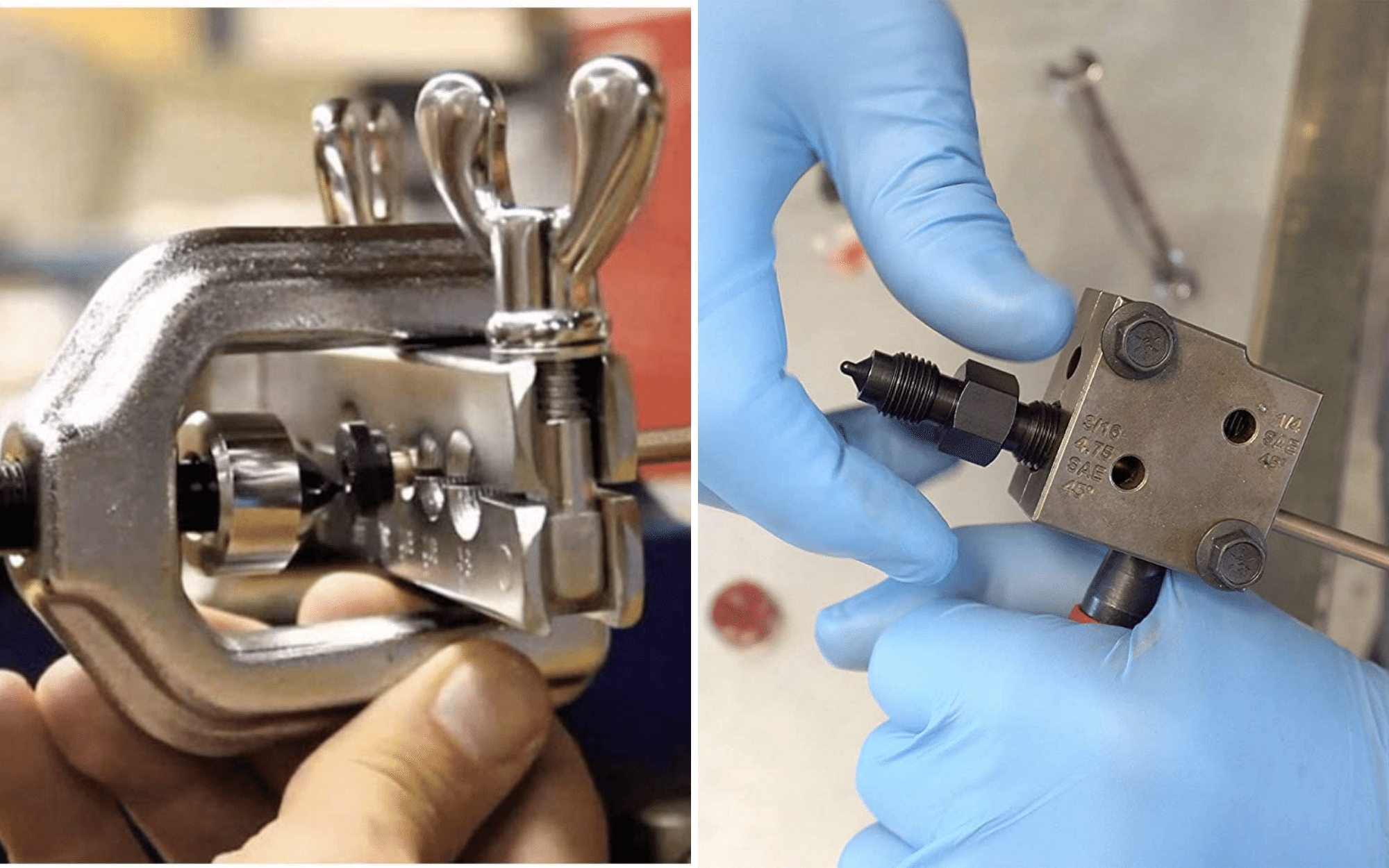

Step-by-Step: How to Use Earl's Professional Flaring Kit

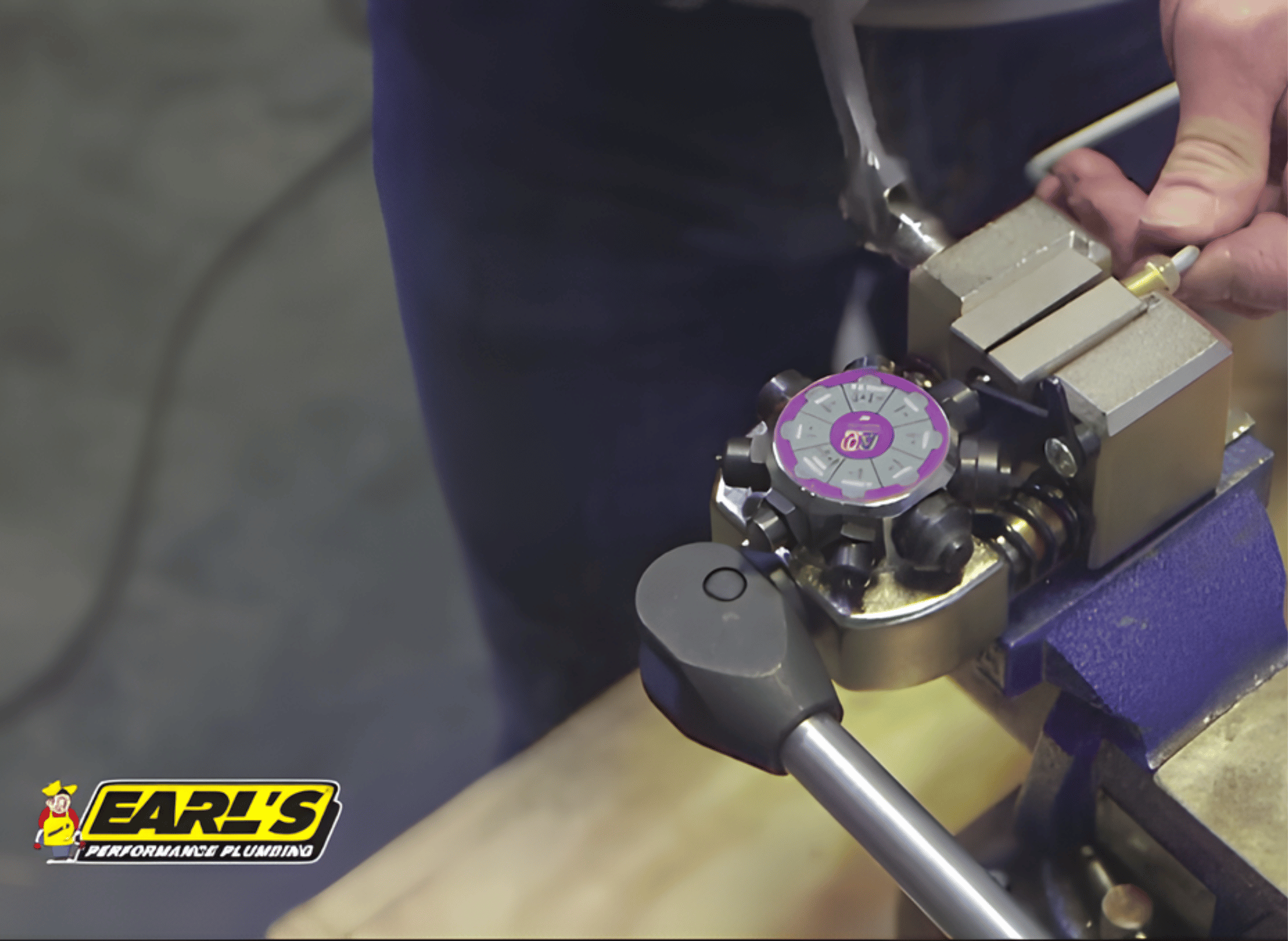

While this is a professional-grade tool, using it doesn't require an engineering degree. However, it does require a bench vise to secure the tool properly. Here is a simplified guide to getting that perfect flare:

- Prep the Tubing: Ensure your tubing is cut square and deburred. A clean edge is critical for a crack-free flare.

- Mount the Tool: Secure the main body of the flaring tool into your bench vise.

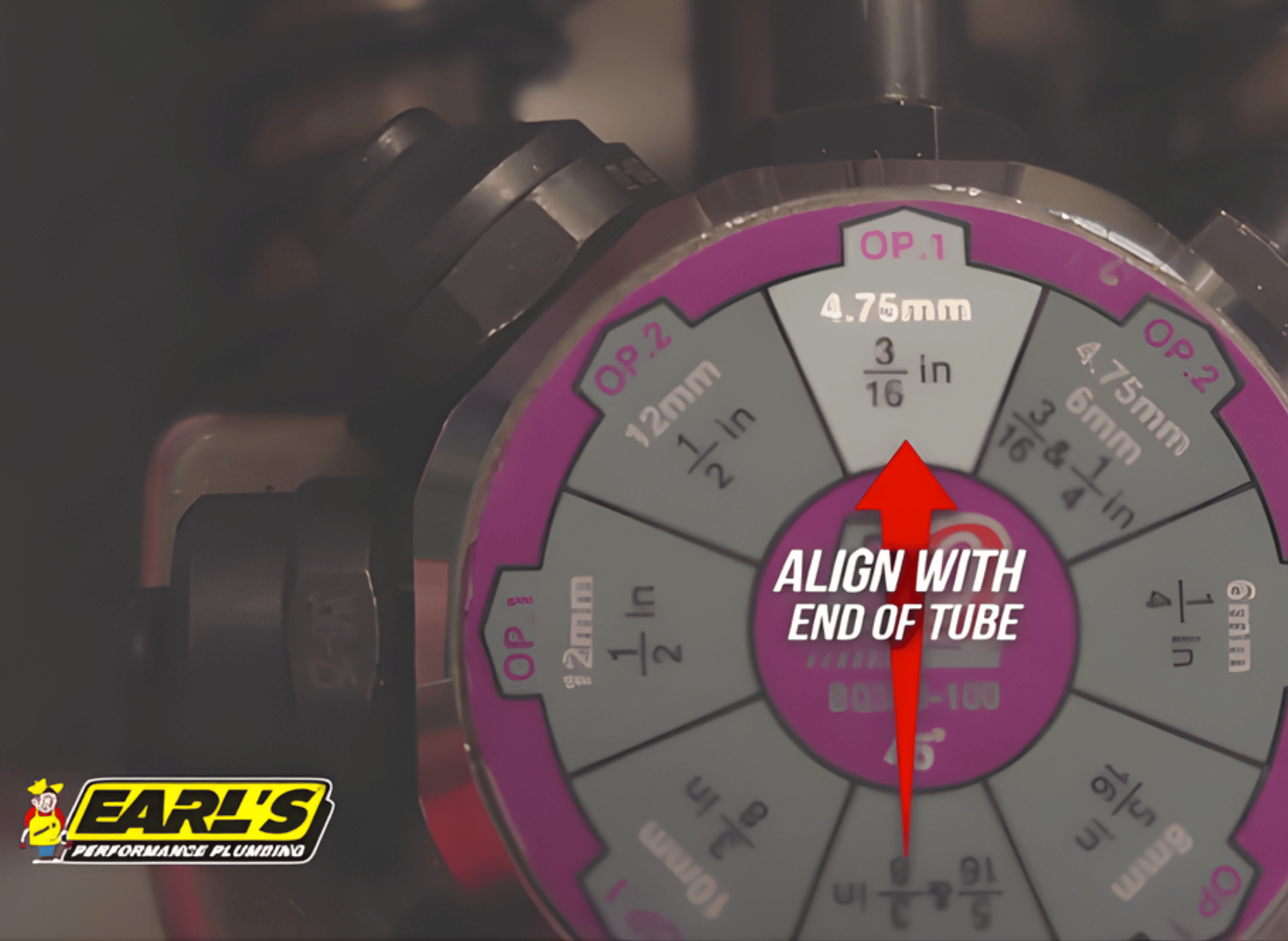

- Select the Dies: Choose the appropriate dies for your tubing diameter and insert them into the tool.

- Position the Tubing: Insert the tubing into the dies. Use the alignment gauge (often the flat side of the turret or a specific stop) to set the correct depth.

- Clamp Down: Tighten the clamping lever to secure the tubing. The internal texture ensures the tube won't slip, even with stainless steel.

- Select the Operation: Rotate the turret to select the correct punch for your flare type (e.g., OP 1 for the first step of a double flare).

- Apply Force: Use the lever to press the punch into the tubing. If doing a double flare, rotate the turret to the finishing punch and apply force again.

- Release and Inspect: Loosen the clamp, remove the tubing, and inspect your work. You should see a smooth, professional-looking surface ready for installation.

Troubleshooting Common Issues

Even the best flaring tool can present challenges from time to time, especially when working with a variety of materials and vehicle fitments. To ensure your Earl’s Performance Flaring Tool 001ERL delivers flawless results, inspect the kit before each use. This not only confirms your tool is ready for action but also helps protect your workflow from potential issues.

Before you start: Always check that your flaring tool is properly set up and that all components are secure. A quick verification ensures that the tool’s hardened steel components, turret, and punches are in optimal condition, reducing the risk of errors during flaring. If your initial checks are clear and the tool operates smoothly, you’re ready to create precise 37°, 45°, or DIN flares.

Double Flare and Tubing Problems: If you’re having trouble forming a double flare, double-check that your tubing is correctly seated and that you’re using the right punches for your chosen material, be it stainless steel, copper, or aluminum. Misalignment or using the wrong set can lead to imperfect flares or even damage to the tubing.

Vehicle Fitment and Material Selection: Always verify that your flaring tool is compatible with your vehicle’s tubing size and material. Consult the manufacturer’s specifications to ensure a perfect fit, especially when working with specialty auto accessories or custom parts.

Professional Flaring Support: Should you run into persistent issues, don’t hesitate to consult the user manual or reach out to Earl’s Performance support team. Their expertise can help you troubleshoot specific problems, from turret alignment to selecting the right punches for your application.

By following these troubleshooting tips and prioritizing both tool and online security, you’ll be able to tackle any flaring challenge with confidence. If you have questions, need further assistance, or want to share your experience, leave a review on the manufacturer’s website or connect with other users. Your feedback not only helps you save time but also supports others in mastering professional flaring with Earl’s Performance tools.

Value, Shipping, and Customer Feedback

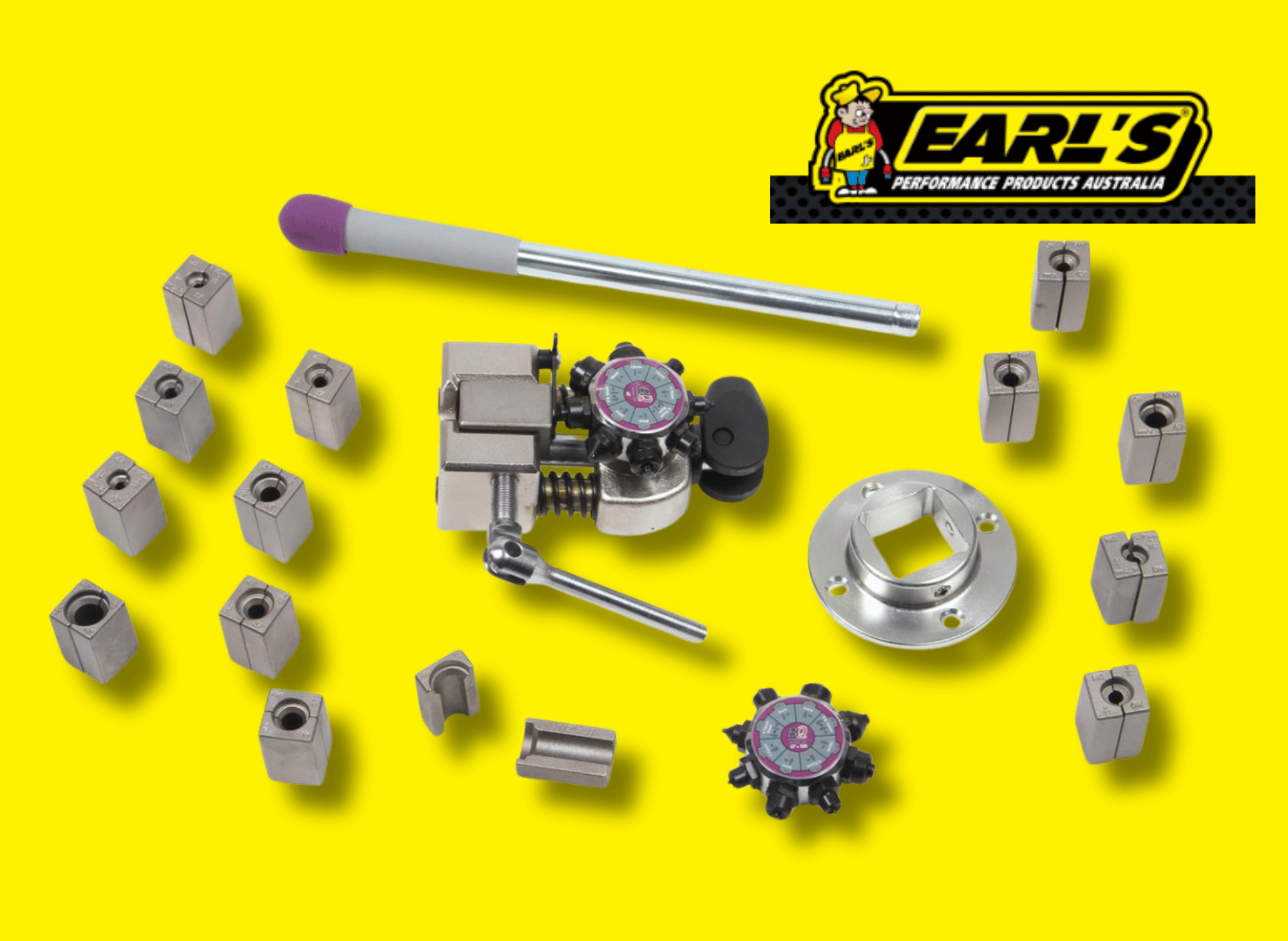

At $716.95, the Earl's Performance 001ERL Professional Flaring Tool is a significant investment. The tool is available for $656.86 with a coupon code and includes free shipping. The previous price was $787.95, and it is now eligible for a price match guarantee. This tool is in stock at multiple retailers. The Professional Flaring Tool includes 15 dies and two turrets for various flare types and materials.

Comprehensive kits include a range of dies and punches to handle different tubing sizes from 3/16 to 1/2 inch. Earl's Performance offers two types of flaring tools: a bench-mount Professional Flaring Tool designed for high-pressure applications, and a compact, hand-held Double Flaring Tool suitable for on-vehicle repairs. These tools maintain high flow rates and pressure ratings required for racing applications.

The smaller Double Flaring Tool is primarily designed for 45-degree single- and double-flare applications and is recommended for specific tubing materials. Professional-grade dies create smooth sealing surfaces that prevent fluid leaks, and the tools are primarily designed for creating leak-free joints in high-pressure systems such as brake and fuel systems.

Users report that Earl's flaring tools make flares quickly in all types of tubing without damaging or deforming the tubing. For those who frequently work on custom lines, the cost is justified by the time saved and the quality of the results. You aren’t just buying a tool; you are buying the ability to manufacture factory-quality parts in your own garage.

When ordering, keep in mind that shipping is often free for orders over $109 from major retailers like Summit Racing, and the estimated ship date is typically immediate if the item is in stock. Always check the returns policy and warranty information to ensure you are covered, though Earl’s reputation suggests you likely won’t need them.

Customer reviews consistently highlight the tool’s reliability. Users frequently reply and mention that while the initial cost is high, the “peace of mind” knowing that brake and fuel lines are secure is worth every penny. If you have questions about vehicle fitment or the compatibility of specific auto accessories, the manufacturer page and Q&A sections are excellent resources.

If you’ve used Earl’s Performance flaring tools, we encourage you to write a review and share your experience with others.

Ready to Upgrade Your Toolbox?

If you are tired of struggling with unreliable, cheap tools that slip and break, it is time to adopt a professional solution for your workflow. The Earl's Performance Flaring Tool 001ERL offers the durability, versatility, and precision required for top-tier automotive work. Don't leave your safety to chance; equip your shop with tools that work as hard as you do.

Thank you for reading!

Your friend,

Todd

#EarlPerformance 🔧 #FlaringTools 💪 #PrecisionMatters 📏 #BuiltToPerform 🚗 #ToolEnthusiast 🛠️ #PerformanceDriven 🏁 #CraftedForExcellence ✨ #AutomotiveTools 🔩 #FlaringDoneRight ✅ #EarlToolsPower 💥