Riveting Results: The Power of a Self-Piercing Rivet Gun

Look no further than the self-piercing rivet gun. This tool revolutionizes how auto body technicians and mechanics work with sheet metals.

Self-piercing rivet guns are specialized tools for joining two or more metal sheets together. They use a unique type of fastener called a self-piercing rivet, designed to pierce and secure multiple layers of sheet metal in one single action.

These guns are commonly used in the automotive, aerospace, and manufacturing industries for their efficiency and accuracy in joining metal components.

How Mechanicaddicts Chooses the Self-Piercing Rivet Gun

Are you looking for the perfect Self-Piercing Rivet Gun? Look no further than Mechanicaddicts. Our expert reviewers have diligently researched various products to provide you with the top options on the market.

Trust us to make your decision-making process more accessible and ensure you get the best product for your needs. Learn more about our selection process and discover the perfect Self-Piercing Rivet Gun for your projects.

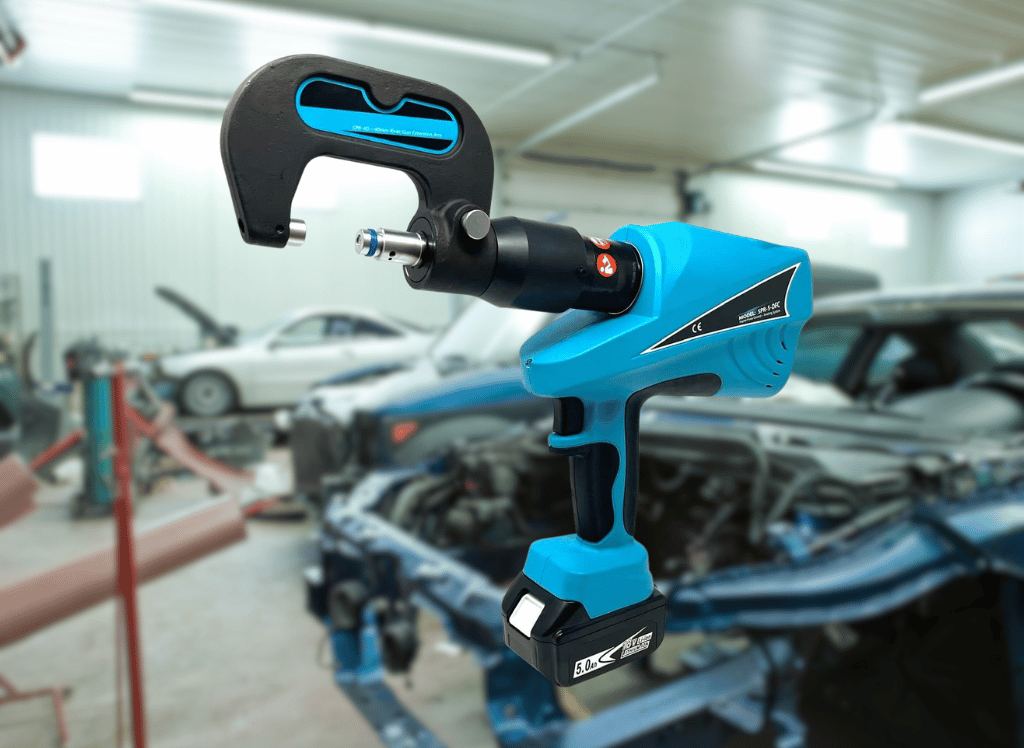

Innovative Tools & Supplies SPR-5-DFC Digital Force Control - Self-Piercing Rivet Gun System

Why We Like This Self-Piercing Rivet Tool

Introducing the Innovative Tools & Supplies SPR-5-DFC Digital Force Control - Self-Piercing Rivet Gun System, the ultimate tool for all your riveting needs. This state-of-the-art system features quick-change extension arms that allow you to access hard-to-reach areas, making any job effortless.

With a simple pin holding them, the extension arms can be easily changed in 5 seconds. The SPR-5-DFC also comes with a threadless magnetic die kit, including 3mm and 5mm SPR dies with magnetic rivet holders for added convenience.

It also includes 3mm and 5mm Rivet Removal dies, 6mm Punching dies for Flow Form spr and solid rivets, Semi-Hollow Rivet Planting dies, Countersunk FFR Rivet Planting dies, Flattening dies, and an Extension adapter. This comprehensive kit ensures you have everything to tackle any riveting task precisely and efficiently.

What You Should Know

The SPR-5-DFC is an advanced Self-Piercing Rivet Gun System designed to increase efficiency and precision in riveting applications. Equipped with a Digital Force Control system, this tool allows users to monitor set and actual pressures through its easy-to-read LCD screen.

With a maximum pressure of 80kN, the SPR-5-DFC can tackle various riveting tasks. Additionally, users can purchase extension arms in lengths of 130mm and 220mm for added versatility. Overall, this innovative self piercing tool is valuable to any workshop looking to enhance their riveting process. So, it can be considered an investment towards increased productivity and quality in manufacturing operations.

With its quick-change arms and precise digital control, the SPR-5-DFC is a cutting-edge solution for all riveting needs. Whether in automotive, construction, or other industrial applications, this tool offers reliability and efficiency to do the job effectively.

Specifications:

- Quick-change extension arms: Enables access to hard-to-reach areas and allows for an easy change in 5 seconds.

- Comprehensive die kit: Includes different types of magnetic dies and an extension adapter for a wide range of riveting tasks.

- Digital Force Control system: Allows users to monitor set and actual pressures through an easy-to-read LCD screen.

- High maximum pressure: With a maximum pressure of 80kN, it can handle various riveting tasks.

- Extension arms availability: Users can purchase extension arms in lengths of 130mm and 220mm for more versatility.

- Versatile applications: Ideal for automotive, construction, and other industrial applications.

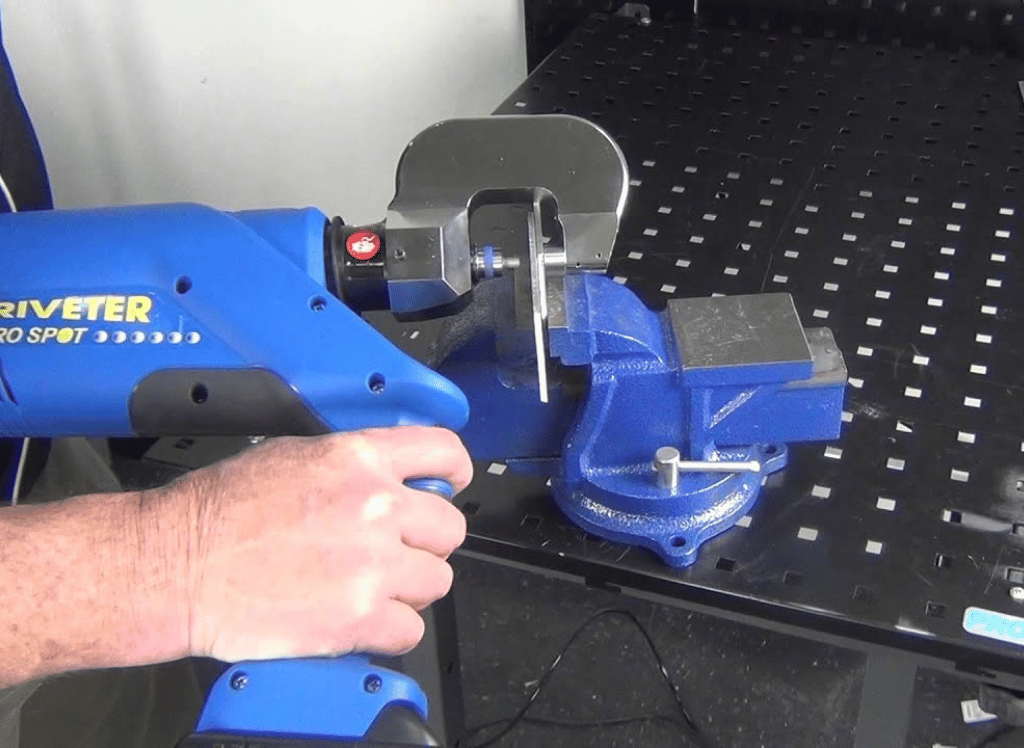

Why We Like This Self-Piercing Rivet Tool

Introducing the CH-SPR-5, a versatile self-piercing rivet gun system with an impressive quick change feature for seamless use. Designed to provide maximum efficiency, this system is compatible with various die styles from multiple manufacturers, making it a valuable addition to any toolkit.

Equipped with a standard 55mm arm, the CH-SPR-5 offers the option to purchase an additional 125mm extension arm for added flexibility. With its user-friendly design and reliable performance, this self-piercing rivet gun system is a must-have tool for professionals in various industries. Upgrade your equipment today with the CH-SPR-5 and experience superior results with every use.

What You Should Know

The Generic Self Piercing Riveting Gun System with Die Kit offers a comprehensive solution for efficient and effective rivet removal and forming.

The Die Kit includes a variety of essential components such as N2 - Rivet Removal Die Female 5mm, N1 - Rivet Removal Die Female 3mm and Flow Form Female, N5 - 3mm Forming Die, N6 - 5mm and 6mm Forming Die, S7 - SPR Holder 3mm with magnet, S9 - SPR Holder 5mm with appeal, S5 - Flattening Dies (2), A1 - Rivet Removal Die Male 3mm, A2 - Rivet Removal Die Male 5mm, A9 - Rivet Flow Form Die Male, A18 - SPR Holder 6mm with magnet, N13 - 5mm Forming Die, and a set of Flow form calibration rings.

These components provide the necessary versatility and precision for various riveting tasks. This system allows users to quickly achieve seamless rivet removal and forming, saving time and effort in their production processes.

The Die Kit is an essential tool for any professional or industrial setting that requires reliable and efficient riveting capabilities. So, it can be a valuable investment for businesses looking to enhance their production processes and achieve optimal results. The CH-SPR-5 Riveter comes with a lithium rechargeable battery and a charging dock.

Specifications:

- Versatility: The CH-SPR-5 Rivet Gun System is compatible with various die styles from multiple manufacturers, ensuring a wide range of applications.

- Expandability: The system offers the option to purchase an additional 125mm extension arm for added flexibility.

- Comprehensive Die Kit: The kit includes numerous essential components such as various rivet removal dies, forming dies, holders, and flow form calibration rings.

- Efficiency: The system allows for quick rivet removal and forming, saving time and effort in production processes.

- Investment Value: Ideal for businesses looking to enhance their production processes and achieve optimal results.

Self-Piercing Rivet Gun Frequently Asked Questions

1. What Is a Self-Piercing Rivet Gun?

A self-piercing rivet gun is a handheld tool for fastening two or more pieces of material together using rivets. Its piercing mechanism allows it to puncture the materials and then attach them with the pin.

2. How Does a Self-Piercing Rivet Gun Work?

A self-piercing rivet gun uses hydraulic or pneumatic pressure to push a piercing punch through the joined materials. Once the punch has created a hole, it inserts and clamps the rivet, securing the materials together.

3. What Are the Benefits of Using a Self-Piercing Rivet Gun?

The main benefit of using a self-piercing rivet gun is its speed and efficiency in joining materials. It also requires less force and physical effort compared to traditional riveting methods. Additionally, self-piercing rivets create solid and secure joints, making them ideal for use in industries such as automotive and construction.

4. Are There Any Safety Precautions to Consider When Using a Self-Piercing Rivet Gun?

Yes, wearing protective gear such as goggles and gloves is essential when operating a self-piercing rivet gun and applying self piercing rivets. Additionally, follow the manufacturer's instructions and never point the tool at anyone else or use it on flammable materials.

5. Can a Self-Piercing Rivet Gun Be Used for All Types of Materials?

No, self-piercing riveting is best suited for joining thin or soft materials such as aluminum, steel, and plastic. It may not work well with thick or rigid materials like hardwood or concrete.

It is always best to check the manufacturer's recommendations for the specific materials you are working with. A self piercing rivet gun can be valuable in various industries and projects, providing efficient and robust fastening solutions.

So, the next time you have a project requiring joining two or more materials, consider using a self-piercing rivet gun for optimal results. This gun is excellent for quick rivet changes when removing rivets during repairs, making you more efficient.

6. Does the Self-Piercing Rivet Gun Have an Integrated Pressure Gauge When Applying Spr for Collision Repair?

Yes, the self-piercing rivet gun typically comes equipped with an integrated pressure gauge to ensure proper and consistent application of SPR (self-piercing riveting) for collision repair. This is important as different materials and thicknesses may require additional pressure to join them properly.

The riveting machine axle also plays a crucial role in the process. It is responsible for driving the rivet into the materials, creating a strong and secure joint.

In addition to its pressure gauge, the self-piercing rivet gun also has features that aid in accurately positioning the rivet. This ensures that it is placed in the correct location for maximum strength and structural integrity.

One of the key advantages of using a self-piercing rivet gun is its ability to join heat sensitive materials without causing damage. This is because the cold joining process of SPR does not require high temperatures, making it suitable for use on materials that cannot withstand heat.

But what if a mistake is made during the riveting process and a rivet needs to be removed? The self-piercing rivet gun can also handle this task with ease. It quickly removes rivets using special bits designed for this purpose.

Additionally, the self-piercing rivet gun allows for quick and easy changes of different sized rivets. This makes it a versatile tool for repair work on various types and sizes of vehicles.

Speaking of vehicles, today's cars are increasingly manufactured with lightweight materials such as aluminum. This makes using self-piercing rivet guns even more critical in collision repair, as traditional welding techniques may not suit these materials.

The self-piercing rivet gun is essential for any collision repair technician. Its integrated pressure gauge, precise rivet positioning, ability to join heat sensitive materials, and quick removal and change of rivets make the repair process more efficient and effective.

Its importance will only grow as vehicles evolve with new materials and technologies. So, investing in a high-quality self-piercing rivet gun is crucial for any modern collision repair shop in today's vehicles.

Final Thoughts About Self-Piercing Rivet Gun

In conclusion, the self-piercing rivet gun is essential for any metalworking professional. Its ability to combine two or more pieces of metal quickly and efficiently has revolutionized the industry.

The self-piercing rivet gun's compact size and simple operation increase productivity and accuracy in metal fabrication projects. It also eliminates the need for additional tools, making it a cost-effective choice for businesses.

Furthermore, the self-piercing rivet gun offers strong and durable joints, ensuring the longevity of any project. It is also versatile and can work with various materials and thicknesses.

#SelfPiercingRivetGun #FasteningSolutions #PrecisionEngineering #Manufacturing #DIYProjects #Tooling #RivetApplications #MechanicalTools #InnovationInEngineering #ConstructionTools

Thank you for reading!

Your friend,

Todd

Are you looking for the best products? We've got you covered! Our editors independently selected each item on this list. Mechanicaddicts may collect a share of sales or other compensation (at no cost to you) from links found within these pages if they choose to buy something (that's how we stay in business); as an Amazon Associate, we earn from qualifying purchases. Reviews have been edited for length and clarity; enjoy finding your next favorite thing today!