Valve Spring Tester: The Secret To High-Performance Engines

Don't guess on your engine build. Use a valve spring tester to measure pressure and coil bind, ensuring peak performance and reliability.

This site contains affiliate links, and we may earn a commission at no extra cost to you. All recommended products are thoroughly vetted.

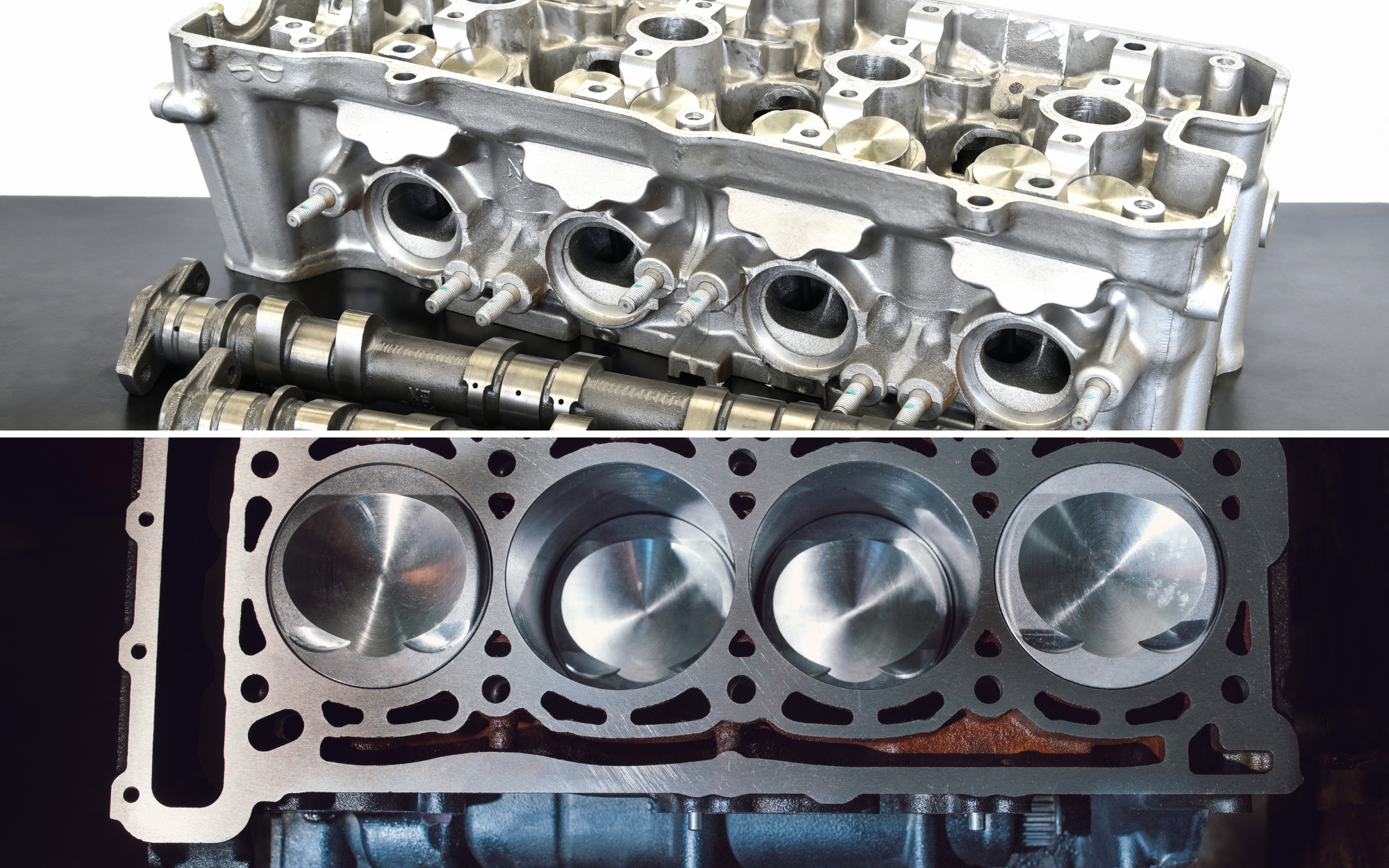

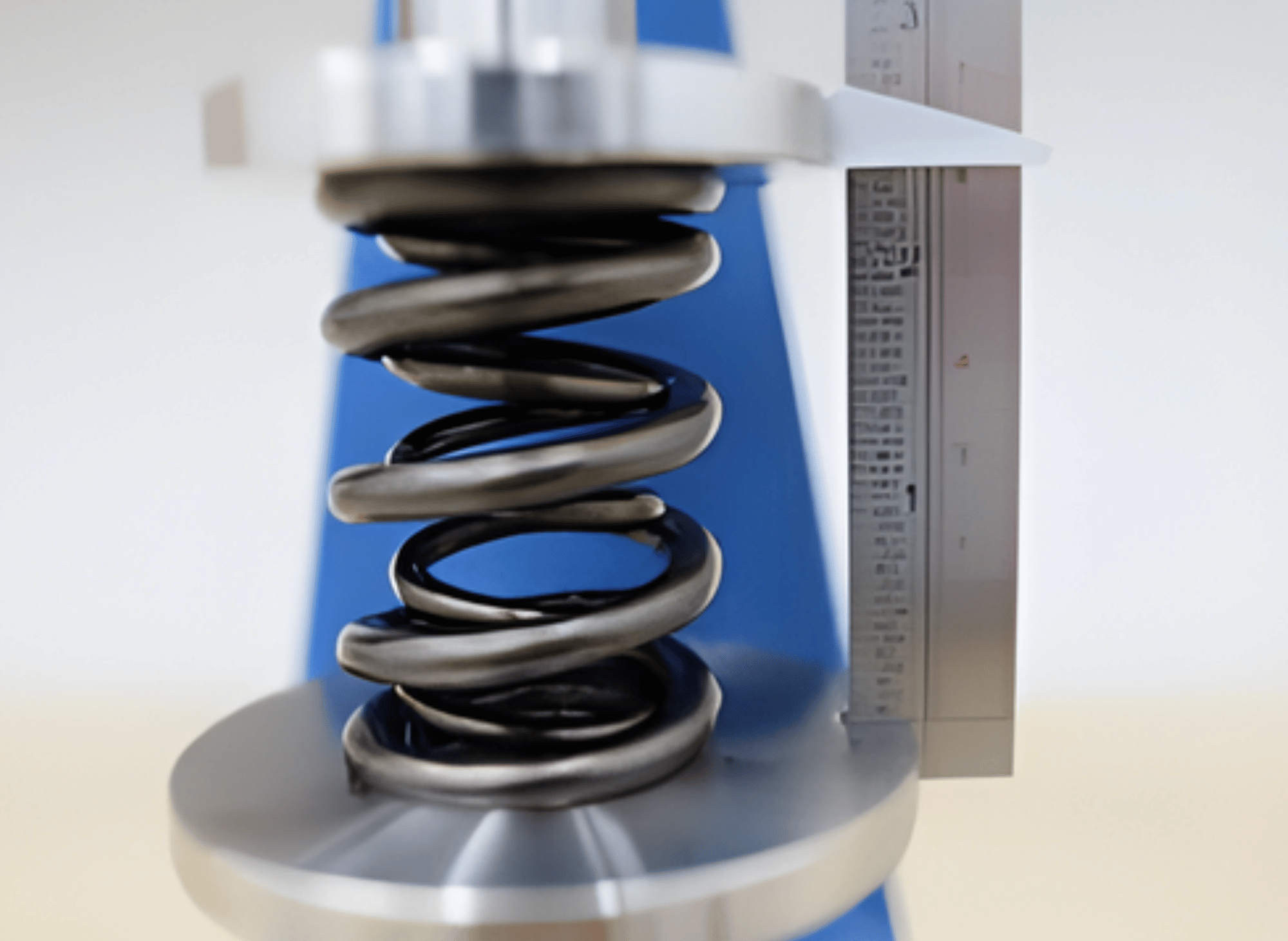

When building an engine, most enthusiasts obsess over the camshaft profile, the cylinder head flow, or the compression ratio. While these are critical, they rely entirely on a small, often overlooked component to function correctly: the valve spring. If your springs aren't up to the task, your high-dollar engine build can turn into a pile of scrap metal in seconds. This is where a quality valve spring tester becomes the most valuable tool in your workshop.

Whether you are a professional engine builder or a dedicated hobbyist, understanding the condition of your springs is non-negotiable. A spring that is too weak can cause valve float at high RPM, leading to lost power or catastrophic piston-to-valve contact. Conversely, a spring that is too stiff can wipe out a cam lobe or cause unnecessary friction and heat.

To find the sweet spot, you need accurate data. You need to know the pressure at the installed height, the open pressure, and the distance to coil bind. In this guide, we will dive deep into valve spring testing, exploring the equipment you need to ensure your engine performs exactly as designed.

The Critical Role of Accurate Testing

An engine is a precise air pump, and the valvetrain controls the flow of air. Testing springs ensures that every valve opens and closes at the exact moment the camshaft dictates. But why is testing individual springs so crucial if you bought them as a set?

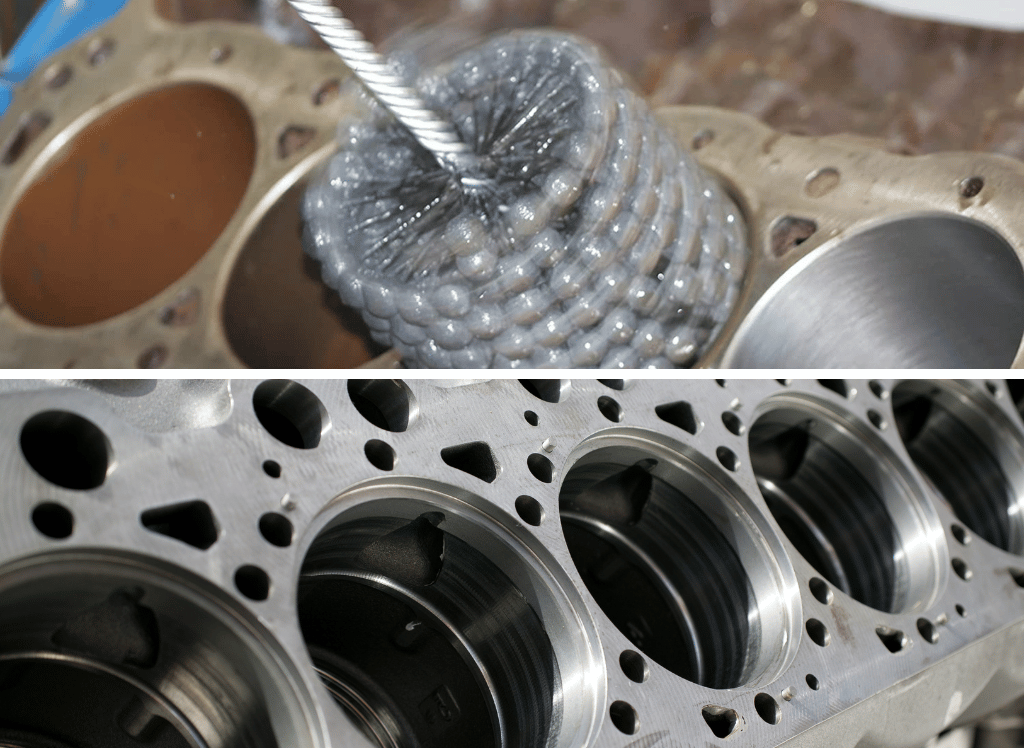

Manufacturing tolerances exist in every product. Even high-end springs can vary slightly out of the box. Furthermore, after an engine has been run, springs lose tension. A tester allows you to verify that a used set is still within range for reuse or if it's time to order new parts. Accurate testing prevents the guesswork that leads to damage and expensive repairs down the road.

History and Evolution of Valve Spring Testers

The concept of measuring spring force isn't new. For nearly a century, mechanics have understood that verifying spring rates is key to reliability.

Since the 1920s, Rimac has been the industry standard regarding these tools. Hardcore engine builders have considered Rimac spring testers the "gold standard" for decades. If you walk into a heritage engine shop, you will likely find an older, heavy-duty Rimac unit bolted to the workbench. These analog behemoths were built to last, often fetching high prices on auction sites because of their reputation for durability.

Over time, the technology has evolved. While the classic analog gauge is still trusted, the market has expanded to include sophisticated digital options. Modern units can now feature a load cell for extreme accuracy, backlit screens, and even software connectivity to print or save data results for client build sheets.

Types of Valve Spring Testers

Choosing the right kit depends on your specific needs, budget, and workspace. Generally, these tools fall into two main categories: bench-mounted and portable/digital.

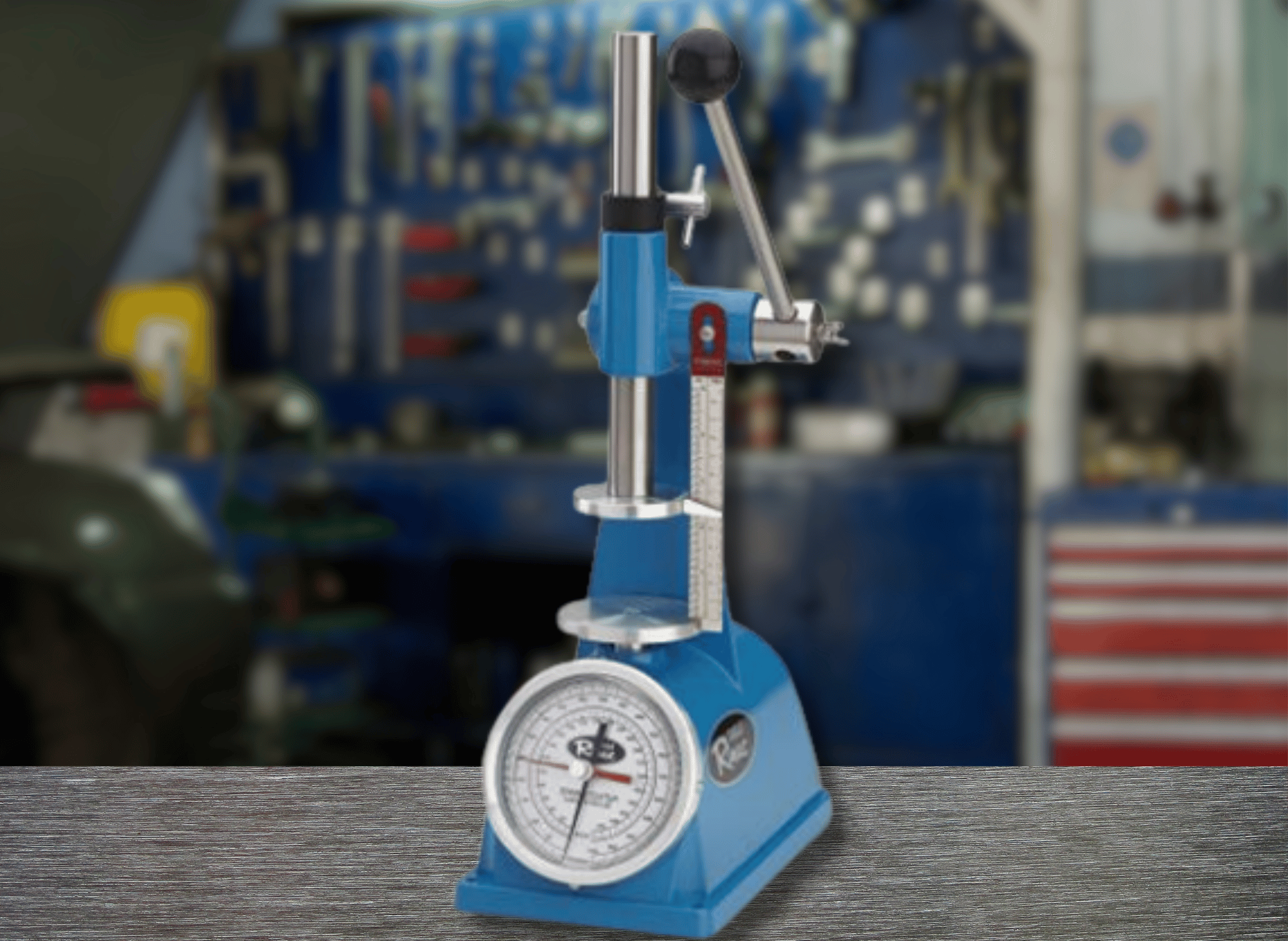

Rimac Big Blue Spring Testers BB1000

Rimac Big Blue valve spring testers feature a pressure range up to 1,000 lbs.-in. These valuable tools can be easily bench-mounted for secure use

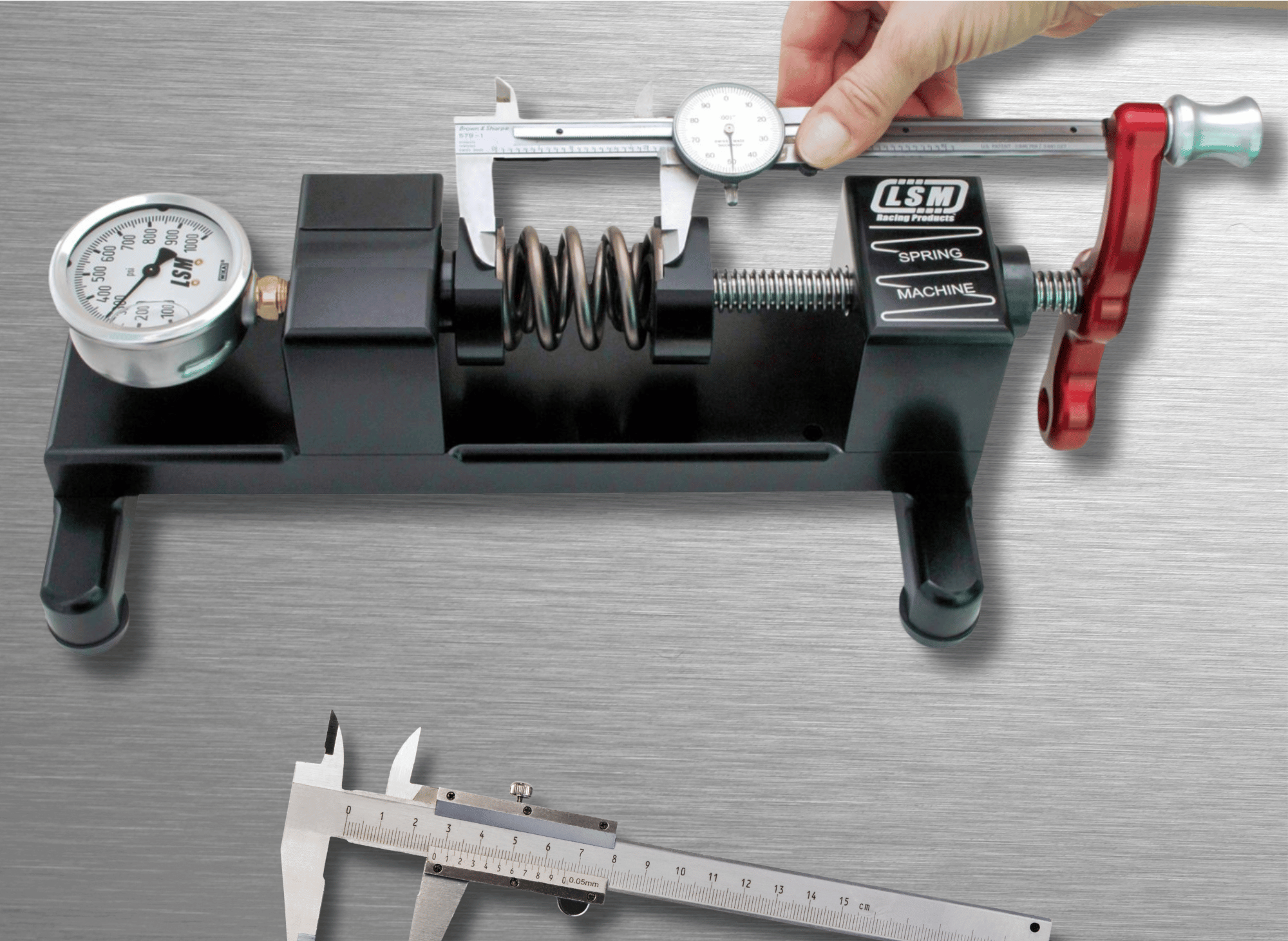

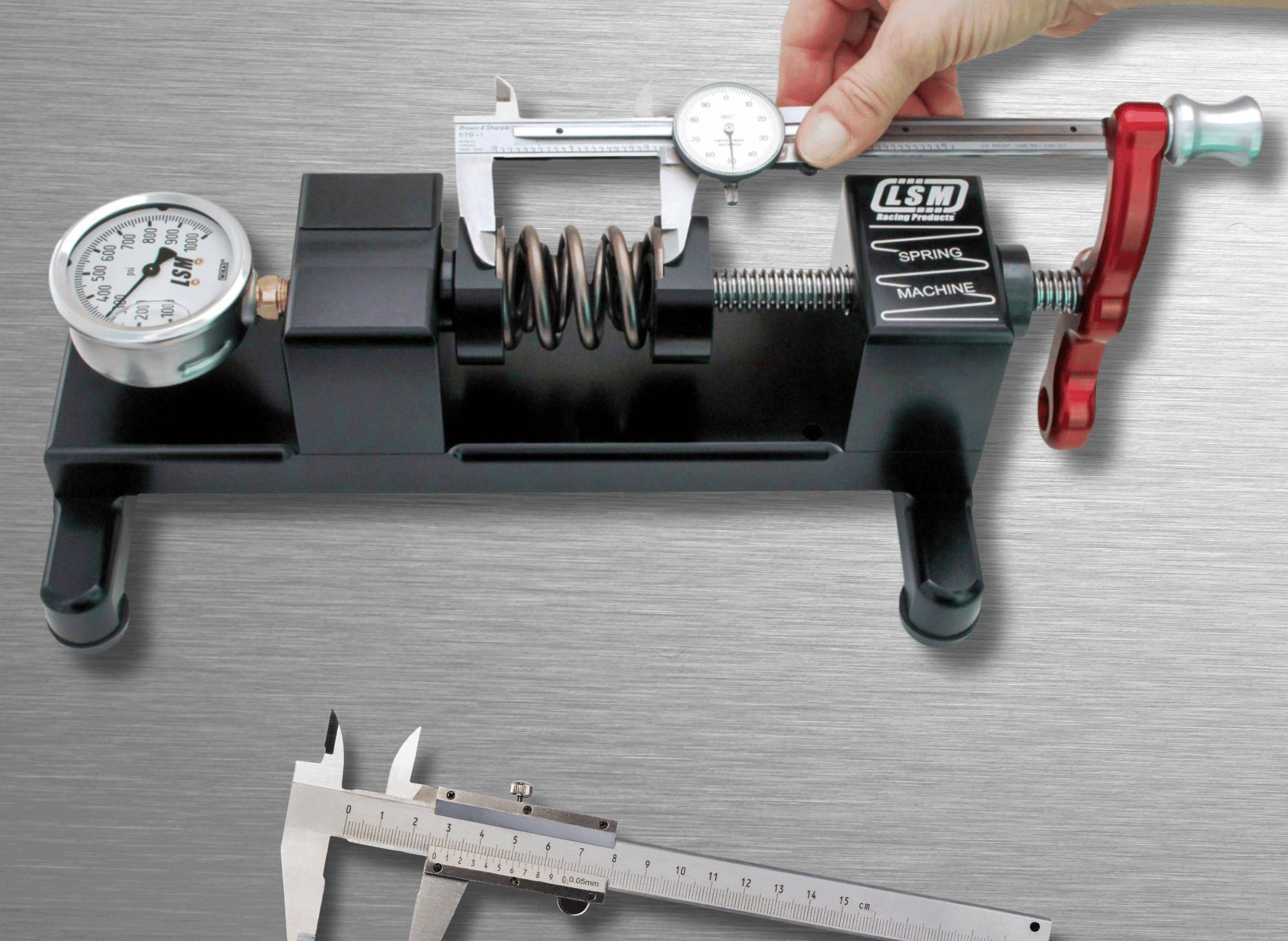

LSM Racing Bench Top Valve Spring Testers SM-1000

They are rugged enough for everyday use in the shop and yet are designed to be taken on the road. These bench-top valve spring testers are available in 1,000-lb or 600-lb ranges.

Bench-Mounted Testers

These are the industry's heavyweights. They are designed to be bolted down for maximum stability, ensuring consistent force application.

- Rimac Big Blue (PRO-BB1000): As mentioned, this is a legend in the field. It features a pressure range of 0-1,000 lbs./in., making it capable of handling everything from stock small-blocks to high-pressure solid-roller setups. It has a robust bench mounting system with holes pre-drilled for security. The analog face is easy to read, and the unit is known for its "Big Blue" powder-coated finish.

- LSM Racing Bench Top (SM-1000): This unit offers a different approach with an innovative horizontal design. It is rugged enough for daily shop use but designed to be portable enough to take to the track. Like the Rimac, it handles up to 1,000 lbs. and provides precision accuracy at the installed height.

Digital and Portable Testers

For those who need to save space or money, or who prefer digital readouts, these are excellent options.

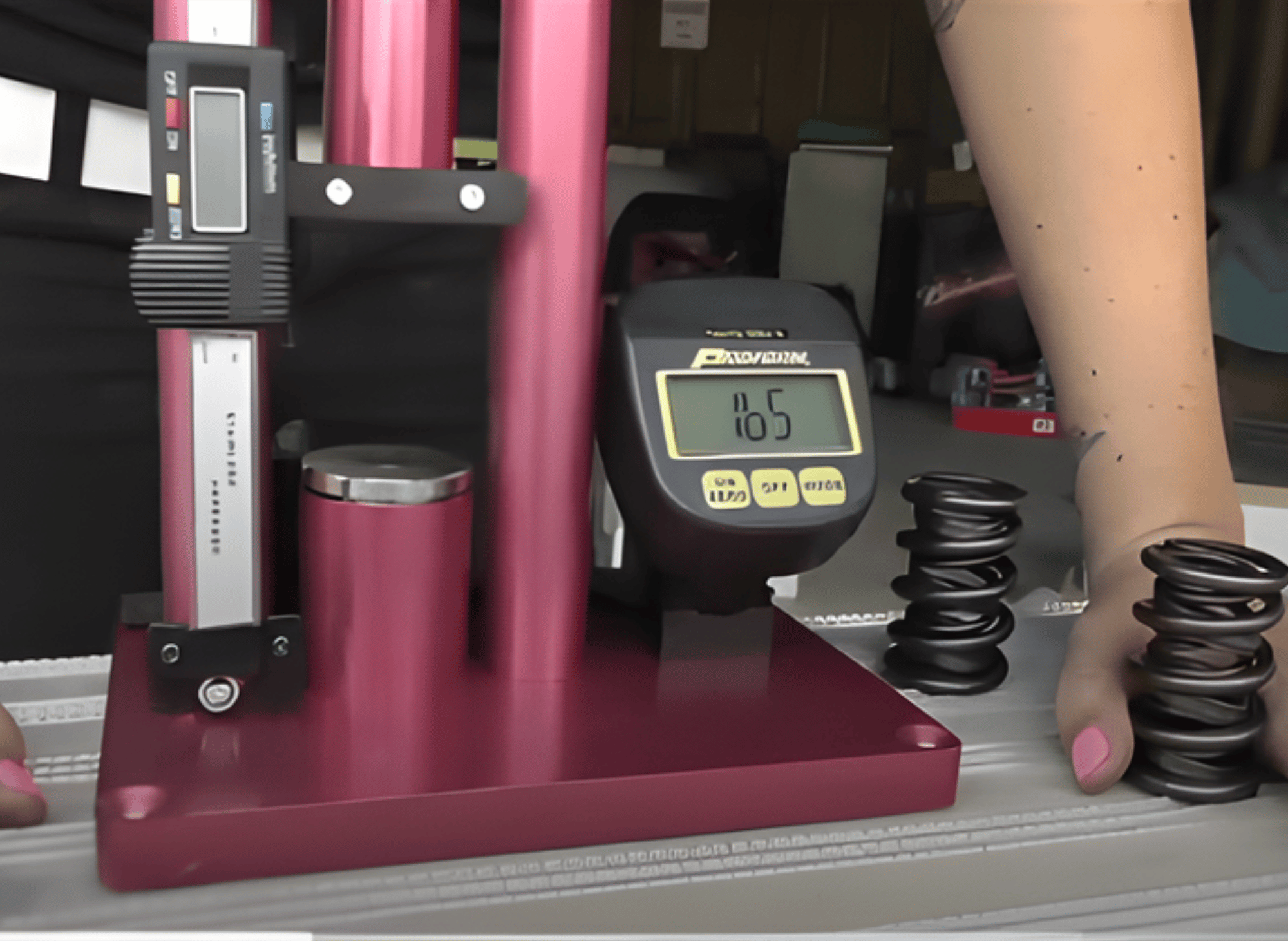

Proform Digital Bench Top Valve Spring Testers 66776

They are manufactured from heavy-duty billet aluminum and can check valve springs with a 1.5 in. diameter and 3 7/8 in. tall. The digital display reads in 1 lb. increments and has backlighting for easy identification.

Intercomp Racing Valve Spring Testers 100057

They're excellent for valve, clutch, shock, and pressure relief springs. These valve spring testers are portable, offer push button on/off and zero to make them user-friendly, and are backlit for night use.

- Proform Digital Bench Top Valve Spring Testers (66776) : These Proform digital bench-top valve spring testers are the most accurate when measuring valve spring pressure. They are manufactured from heavy-duty billet aluminum and can check valve springs from 1.5 in. diameters and 3 7/8 in. tall. The digital display reads in 1 lb. increments and has backlighting for easy identification. The Proform digital benchtop valve spring testers also feature peak hold and automatic shut-off.

- Intercomp Racing Valve Spring Testers (100057): These Intercomp Racing valve spring testers provide high accuracy and repeatability with digital force and travel indication. They're excellent for valve, clutch, shock, and pressure relief springs. These valve spring testers are portable, offer push-button on/off and zero to make them user-friendly, and are backlit for night use.

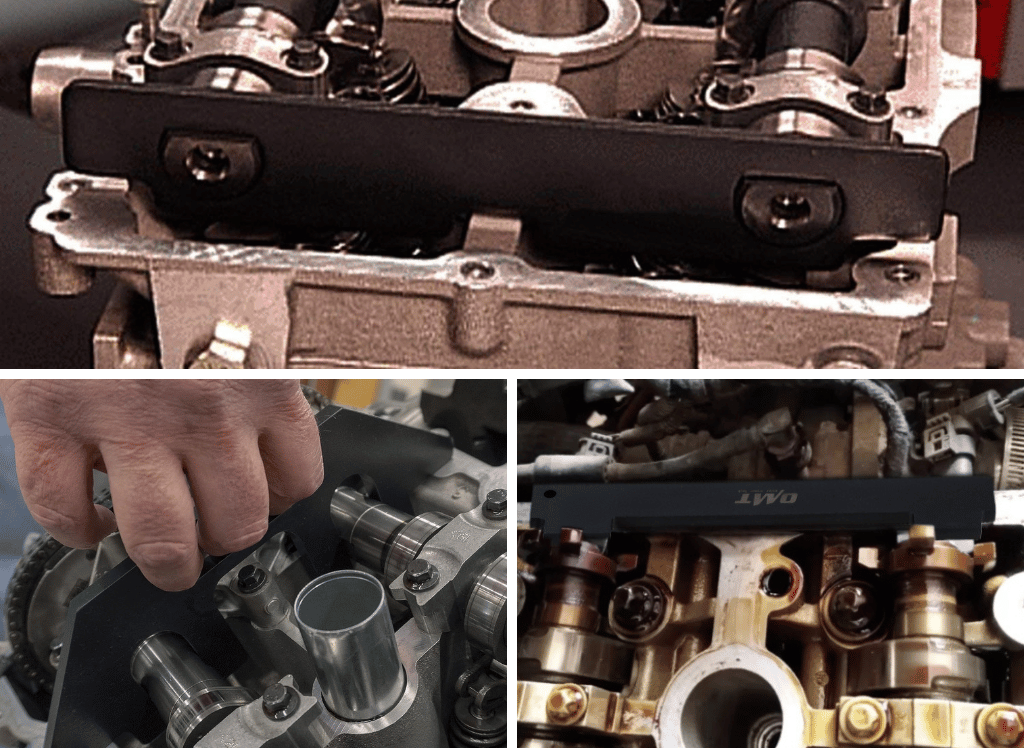

On-Head Spring Testers

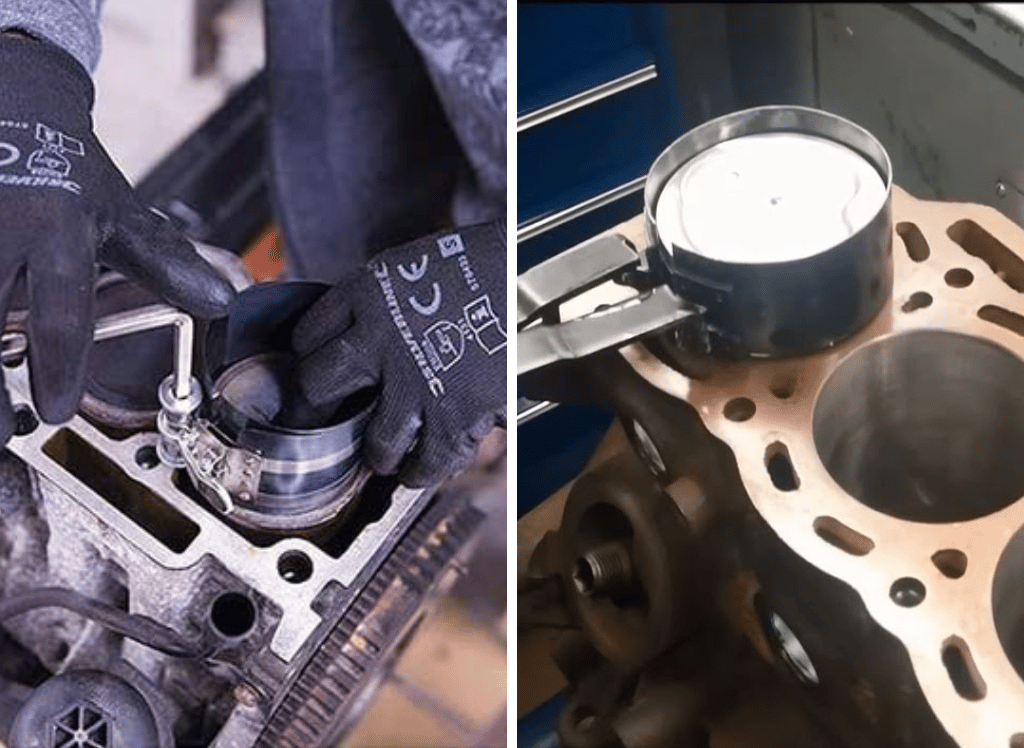

Sometimes you need to test a spring without removing the cylinder head. An on-head spring tester allows you to check seat pressure with the valvetrain still assembled. This is crucial for routine maintenance on race engines to ensure springs haven't fatigued between rounds.

COMP Cams Adjustable On-Head Valve Spring Testers 5639CPG

Made of high-quality billet aluminum, they are designed to fit onto your rocker arms for quick pressure checks. These valve spring testers are adjustable to work with almost any length of rocker arm and can measure pressure up to 600 lbs.

COMP Cams Adjustable On-Head Valve Spring Testers (5639CPG): COMP Cams adjustable on-head valve spring testers are a great way to check your spring pressure on an assembled engine. Made of high-quality billet aluminum, they fit your rocker arms for quick pressure checks. These valve spring testers are adjustable to work with almost any rocker arm length and can measure pressure up to 600 lbs.

Key Features and Specifications

When shopping for a valve spring tester, dig into the details to ensure it matches your requirements. A quality valve spring tester kit often includes essential accessories such as adapters, calibration tools, and detailed instructions.

Pressure Range and Increments

The range is the most critical spec. A stock engine might only need a tester that reads up to 300 or 400 lbs. However, a high-performance drag racing engine might require a unit that can read up to 1,000 lbs. Look for fine increments (e.g., 5 lbs or 1 lb) to ensure precise measurement.

Mounting Options

Stability is key. A bench model sits firmly, allowing you to pull the handle smoothly. A mini-tester often requires a vise to hold it steady. Ensure you have the space and equipment to mount the tool safely.

Readability

Analog gauges are great because they don't require batteries and provide a visual sweep that some builders prefer. However, a digital screen eliminates parallax error (reading the needle from an angle) and often provides exact numbers down to the decimal.

Adjustability and Capacity

Check the physical capacity of the tester. Can it handle the diameter of your springs? Is the vertical travel sufficient for the free length of your springs? Most quality units are adjustable to accommodate various spring sizes.

How to Choose the Right Valve Spring Tester

Selecting the right product involves balancing price against performance.

- Intended Use: Are you building one engine a year in your garage, or are you running a machine shop? A professional should invest in a heavy-duty model like the Rimac or LSM. A hobbyist might find the Proform digital tester perfectly adequate.

- Budget Considerations: Price varies significantly. A Rimac Big Blue runs over $1,000, while smaller handheld or vise-mounted units can be found for under $200.

- Space: If you don't have a dedicated workbench, a large bench-mounted unit might be in the way. A portable unit that fits in a drawer might be the better find.

Step-by-Step Guide to Using a Valve Spring Tester

Using these tools is straightforward, but consistency is vital.

1. Setting Up the Tester

Secure the tester. If it’s a bench model, bolt it down through the mounting holes. If it’s a vise model, clamp it securely, but be careful not to damage the body. Ensure the ram or plunger is aligned with the center of the spring pad.

2. Zeroing and Calibration

Before placing a spring, ensure the gauge reads zero. If using a digital unit, turn it on and let it run its self-check.

3. Measuring Installed Height

Determine the installed height required for your cylinder heads. Adjust the tester so that you are compressing the spring to this exact height. Many testers have a built-in ruler or adjustable stop to help with this.

4. Performing the Test

Place the spring in the middle of the pad. Compress the spring until you reach the installed height. Read the pressure on the gauge or screen. This is your seat pressure.

Next, compress the spring further to the open valve height (installed height minus valve lift). This is your open pressure.

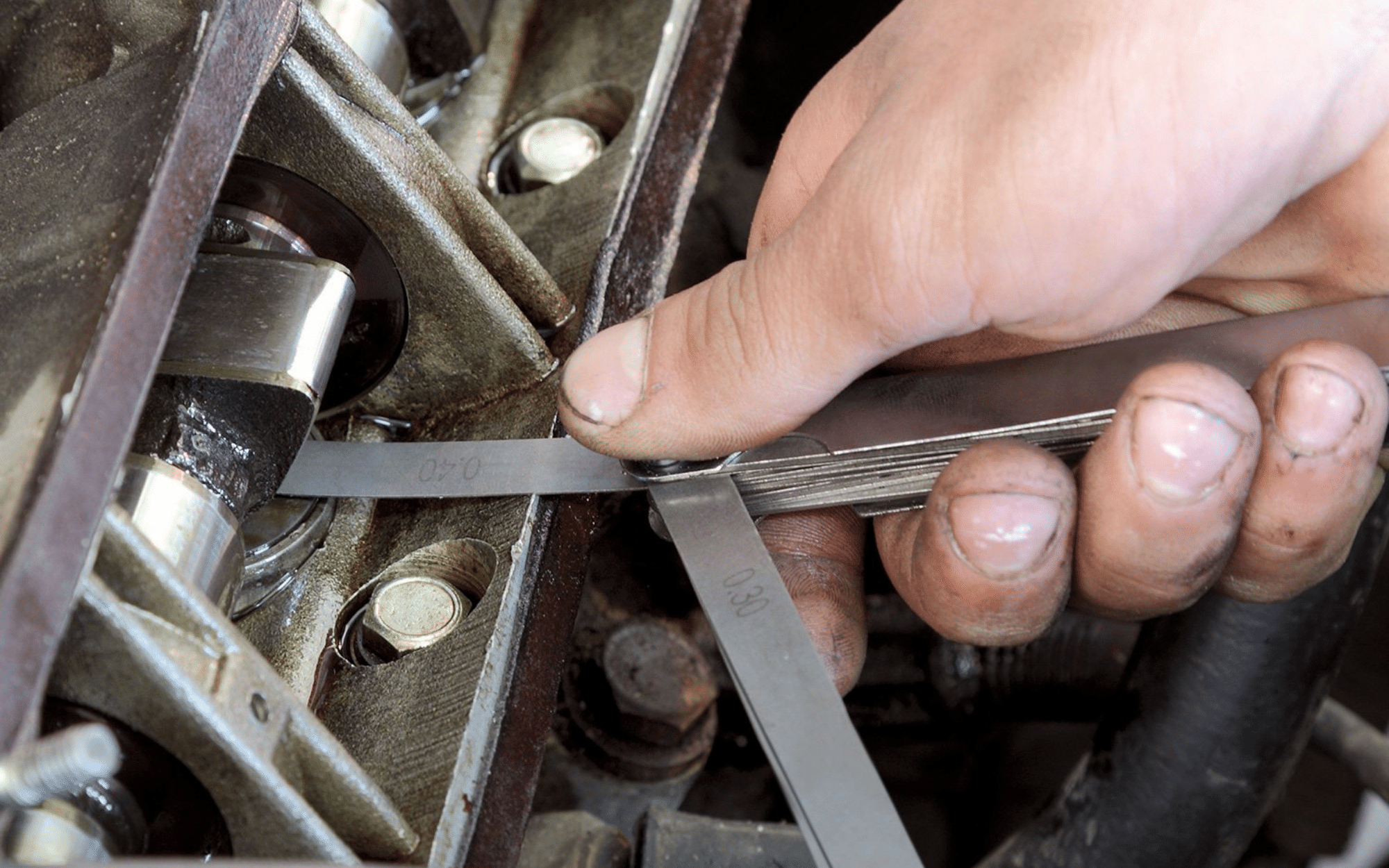

Finally, compress until the coils touch. This is the coil bind height. Ensure you have the recommended clearance (usually .050" to .060") between max lift and coil bind.

5. Recording Results

Write down every number. Compare the results across the entire set. If one spring is significantly weaker or stronger, it should be replaced.

Best Practices for Valve Spring Testing

To get the most out of your valve spring tester, follow these best practices.

- Consistent Procedures: Always pull the handle at the same speed. Rapid compression can yield different numbers than a slow, steady squeeze.

- Check for Retainers: When testing, decide if you are testing just the spring or the spring with the retainer. The retainer changes the height, so account for its thickness in your measurements.

- Regular Maintenance: Keep the tester clean. If it’s hydraulic, check for leaks. If it’s digital, keep spare batteries.

- Safety First: Springs store a massive amount of energy. If a spring slips out of the tester, it can become a dangerous projectile. Always wear eye protection and ensure the spring is seated correctly before applying force.

Real-World Applications and Benefits

Investing in accurate testing equipment pays dividends in engine longevity and performance.

- Improving Engine Performance: By ensuring all springs have equal pressure, you ensure balanced combustion and smooth power delivery.

- Preventing Engine Damage: Catching a weak spring before it goes into the engine saves you from dropped valves and destroyed pistons.

- Ensuring Compliance: For racing classes with strict rules on valvetrain components, a tester ensures your engine is legal and won't be disqualified.

Frequently Asked Questions

Can I upgrade my analog tester to a digital one?

In some cases, yes. There are retrofit kits available that replace the analog gauge with a digital sensor and screen. However, it often makes more sense to buy a unit that is digital from the factory to ensure accuracy.

What does "ships today" mean on parts websites?

When you see ships today, it usually means the item is in stock and will leave the warehouse immediately. For example, an order placed in late December may have an estimated arrival date of Jan 5th. Whether you are in the US or the Netherlands, checking availability is key to keeping your build on schedule.

Do I need software to use a digital tester?

Most digital testers work as standalone units. However, some high-end industrial models allow you to connect to a PC to graph the spring rate curve. This optional feature is generally used by suspension engineers or top-tier engine developers.

Our Conclusion

The valve spring is the unsung hero of the internal combustion engine. It works harder than almost any other part, enduring millions of cycles under immense stress. A valve spring tester gives you the insight needed to ensure those components are up to the challenge.

Whether you choose the legendary Rimac Big Blue, the versatile LSM Racing bench unit, or a portable Proform digital tester, the investment is small compared to the cost of an engine failure.

By incorporating rigorous testing into your build process, you guarantee that your engine has the reliability to go the distance and turn the pages on gueswork and maximise generated performance to lead the pack. Take the guesswork out of your valvetrain. Equip your shop with the right tester and build with confidence.

Thanks for reading!

Your friend,

Todd

#ValveSpringTester 🛠️ #EnginePerformance 🚗 #PrecisionTesting 🔧 #AutomotiveTools 🏎️ #SpringTesterTech ⚙️ #EngineTuning 🔥 #MechanicalEngineering 🛞 #PerformanceParts 🚀 #ToolInnovation 🛠️ #EngineMaintenance 🛡️