ZStem Crankshafts: High Performance at a Reasonable Price

High-performance crankshafts can boost your engine's power, durability, and efficiency. Learn the materials and benefits.

High-PerformanceWelcome to Mechanicaddicts. As an Amazon Associate, we earn from qualifying purchases (at no cost to you) from links found within these pages if you choose to buy something.

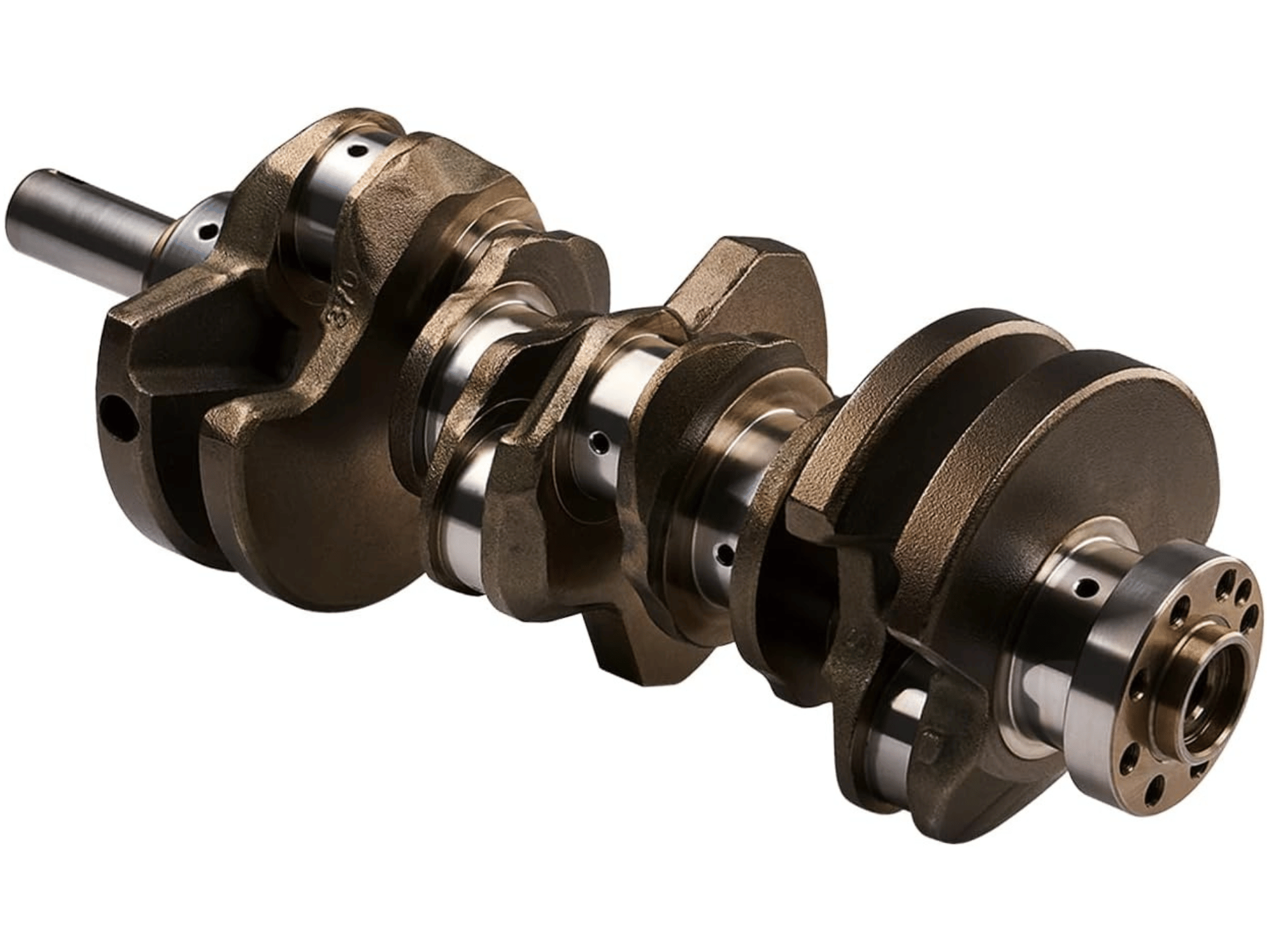

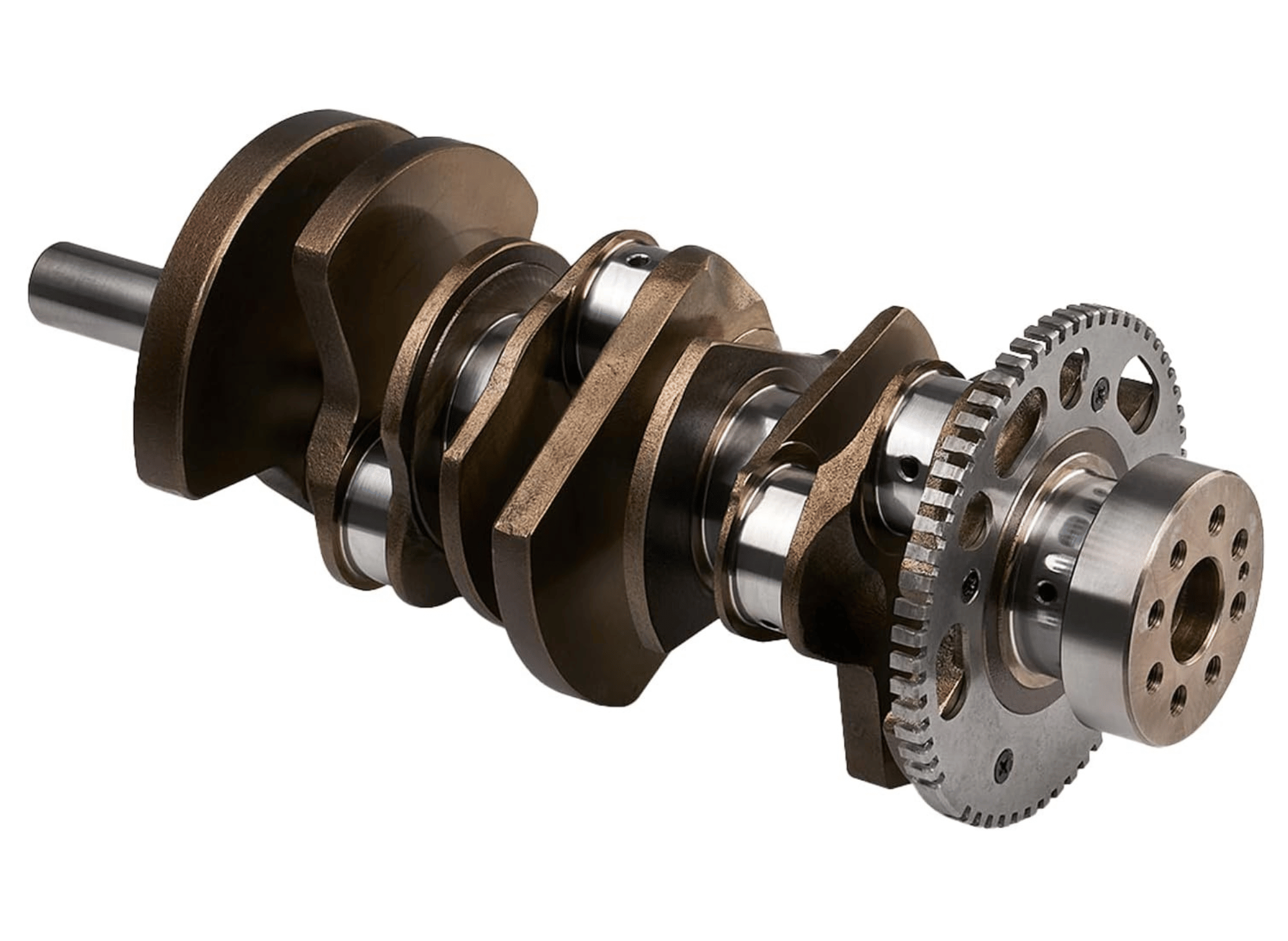

For any automotive enthusiast, the heart of the vehicle is its engine, which is vital for the automotive community. The roar, the power, and the smooth delivery of speed are all products of a complex and beautifully synchronized system of moving parts. At the core of this mechanical ballet is the crankshaft, a component so vital that its performance dictates the engine’s overall power, efficiency, and longevity.

The action of the crank mechanism converts the linear motion of the pistons into rotational motion, enabling the engine to deliver usable power to the drivetrain. Throughout history, cranks have played a significant role in mechanical systems, from ancient devices to modern engines, facilitating the conversion of motion and driving engineering innovation. While stock crankshafts are designed to meet standard factory specifications, a high-performance crankshaft can unlock a new level of capability.

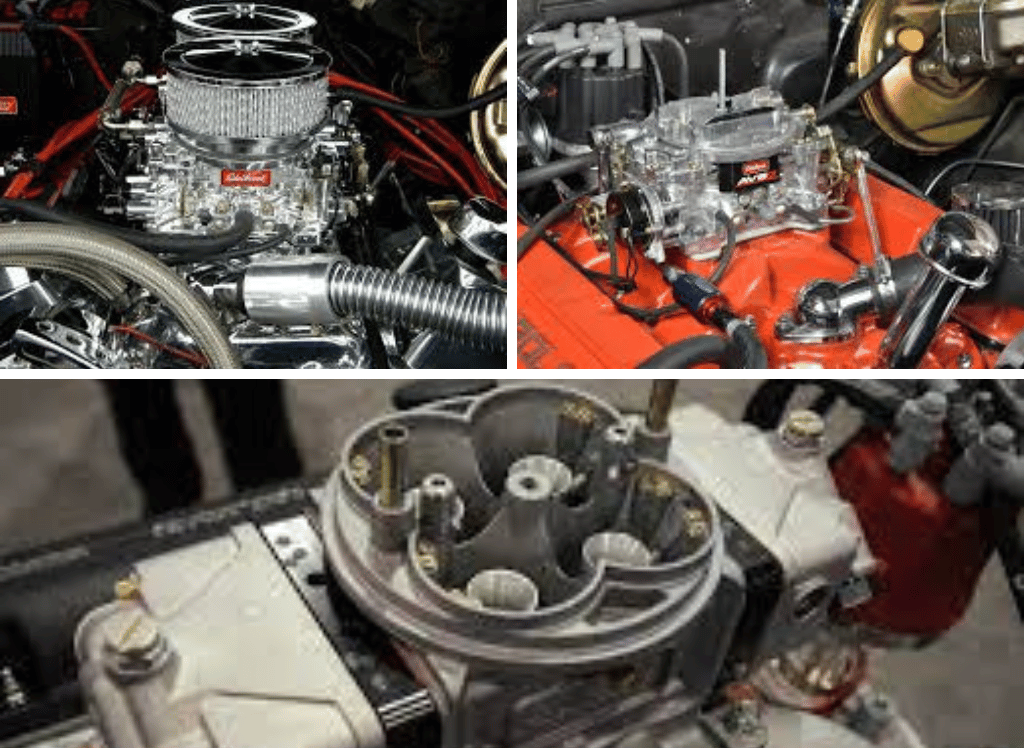

The demand for these upgraded components is on the rise as more drivers and mechanics seek to maximize their vehicles’ potential. Whether you’re tuning a muscle car, modifying a modern turbo engine, or simply aiming to restore and enhance an older vehicle, understanding the benefits of a high-performance crankshaft is essential.

High-performance crankshafts offer several advantages over stock options, including increased strength, reduced weight, and improved durability, which translate to better engine performance and reliability. This guide will cover what makes these components special, the performance gains they offer, and how to select the right one for your engine.

Understanding the Crankshaft

Before we explore high-performance options, it’s essential to understand the fundamental role of a crankshaft and the services it can provide in different applications.

This crucial component is responsible for one of the most critical transformations in an internal combustion engine. Crankshafts and similar mechanisms have also been essential in a wide range of machines beyond automotive engines, underscoring their broader mechanical significance.

What Is a Crankshaft?

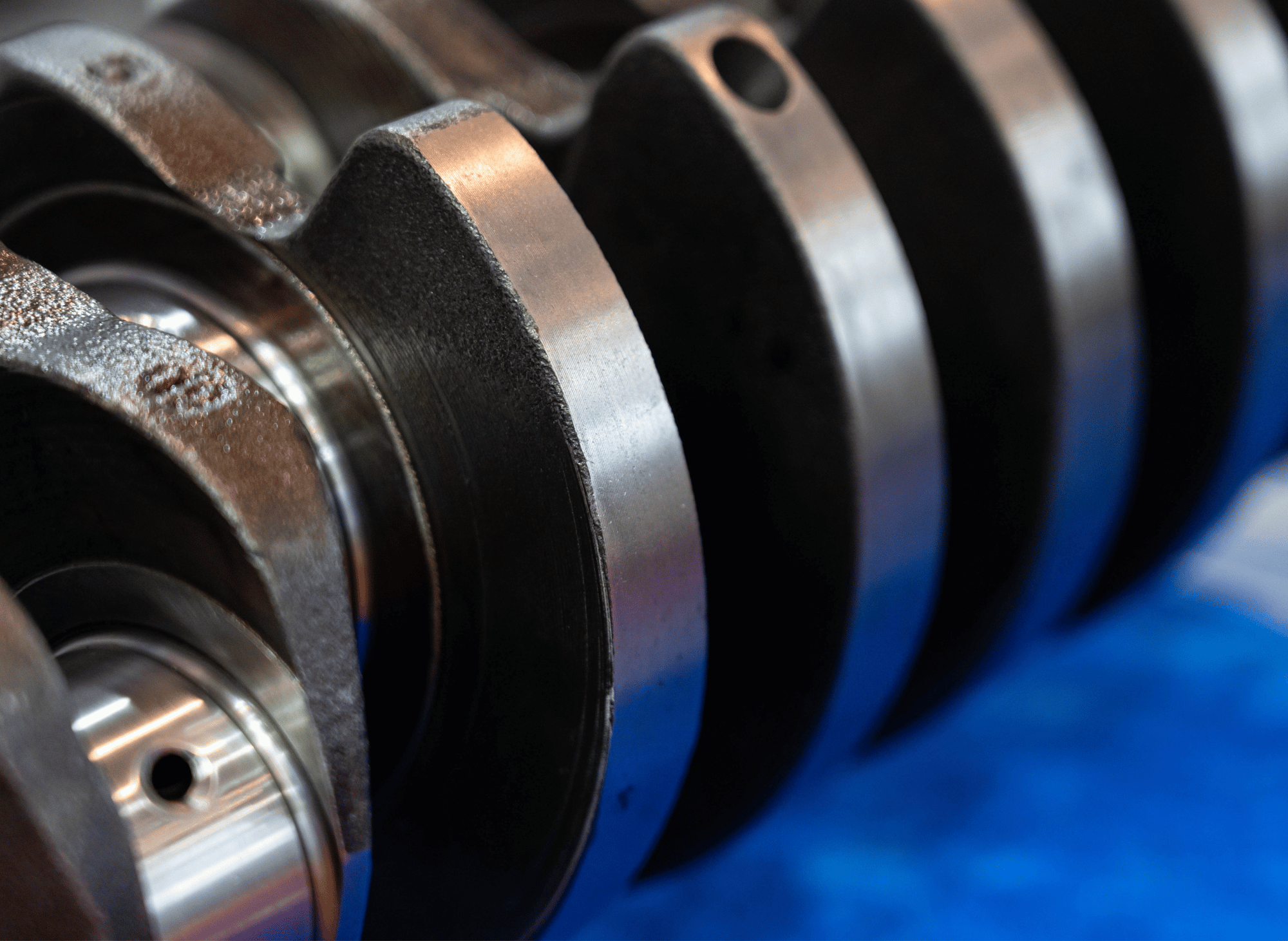

A crankshaft is a rotating shaft that converts the linear, up-and-down motion of the engine’s pistons into rotational motion by means of its unique shape and design. As the fuel-air mixture combusts in the cylinders, it forces the pistons downward.

The pistons are connected to the crankshaft via connecting rods, and this force causes the crankshaft to spin. This rotation is then transferred through the flywheel and transmission to the vehicle’s wheels, ultimately propelling the car forward. In essence, the crankshaft is the backbone of the engine’s power delivery system.

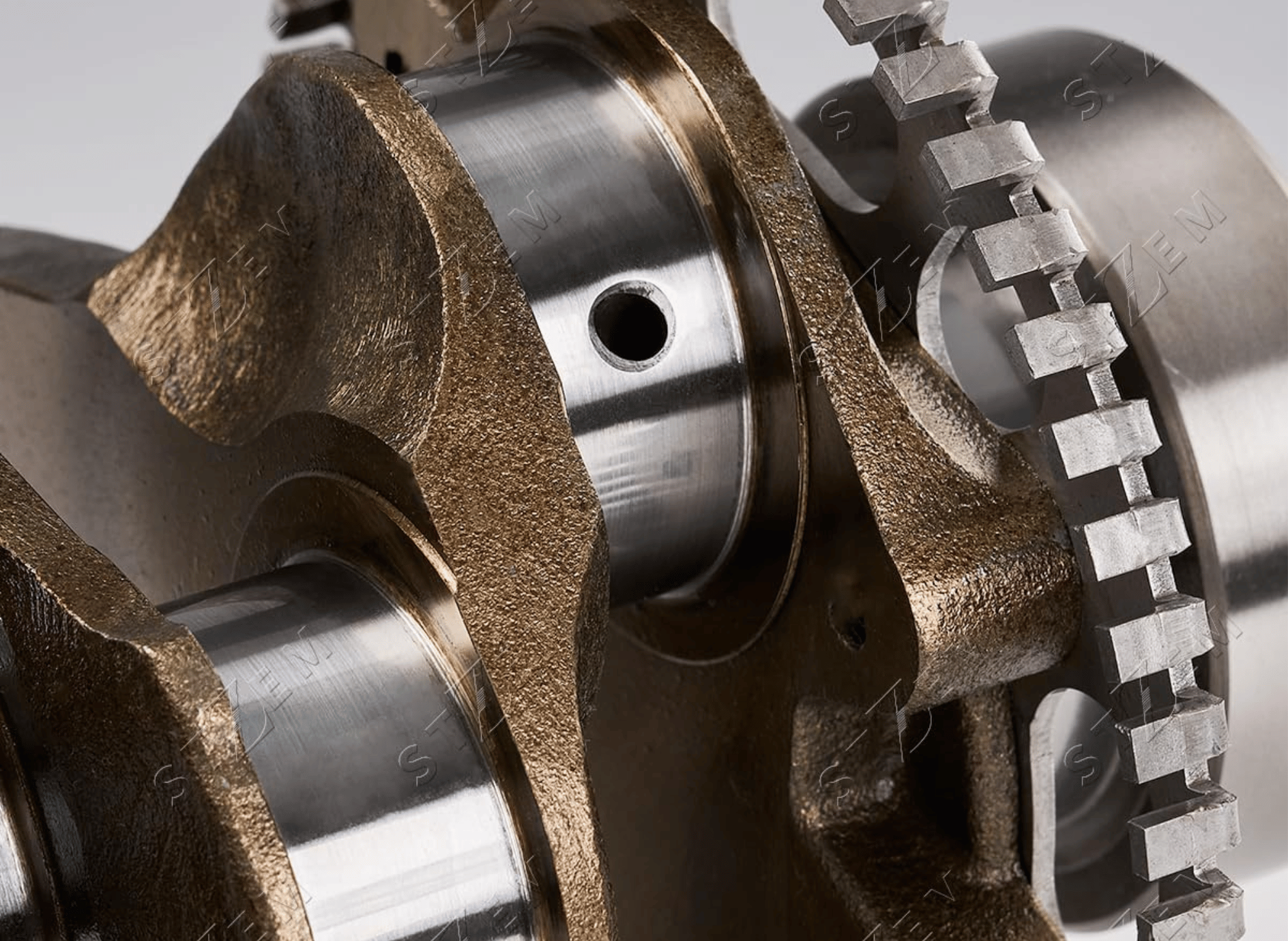

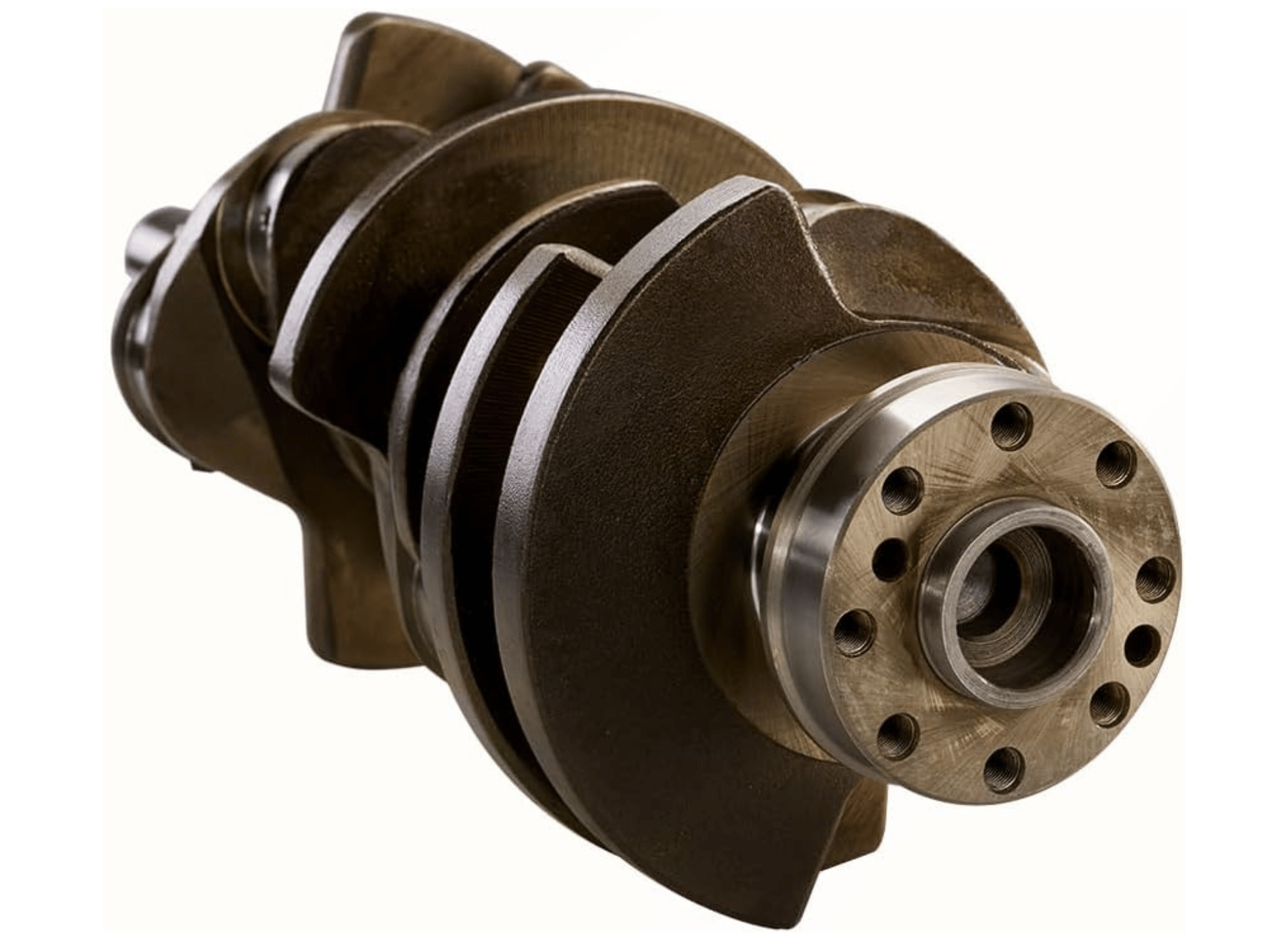

Key Components of a Crankshaft

A crankshaft is a meticulously engineered component that can sometimes be expensive, with several key parts that work in harmony:

- Main Journals: These are the primary rotational points of the crankshaft, which sit within the engine block on main bearings. They form the central axis around which the entire assembly spins.

- Rod Journals: Also known as crankpins, these are offset from the main journals. The “big end” of the connecting rods attaches to these journals, allowing the force from the pistons to be transferred to the crankshaft. Conrods are attached to the crankshaft at these points, forming a critical mechanical linkage in the engine assembly.

- Counterweights: Positioned opposite the rod journals, these heavy weights are designed to balance the forces generated by the reciprocating piston and connecting rod assemblies, including the conrods, which generate forces that require precise balancing. This balancing is crucial for reducing vibration and ensuring the engine runs smoothly, especially at high RPMs.

- Crank Web: The sections of the crankshaft that connect the main journals to the rod journals are known as webs.

Crankshaft Configurations

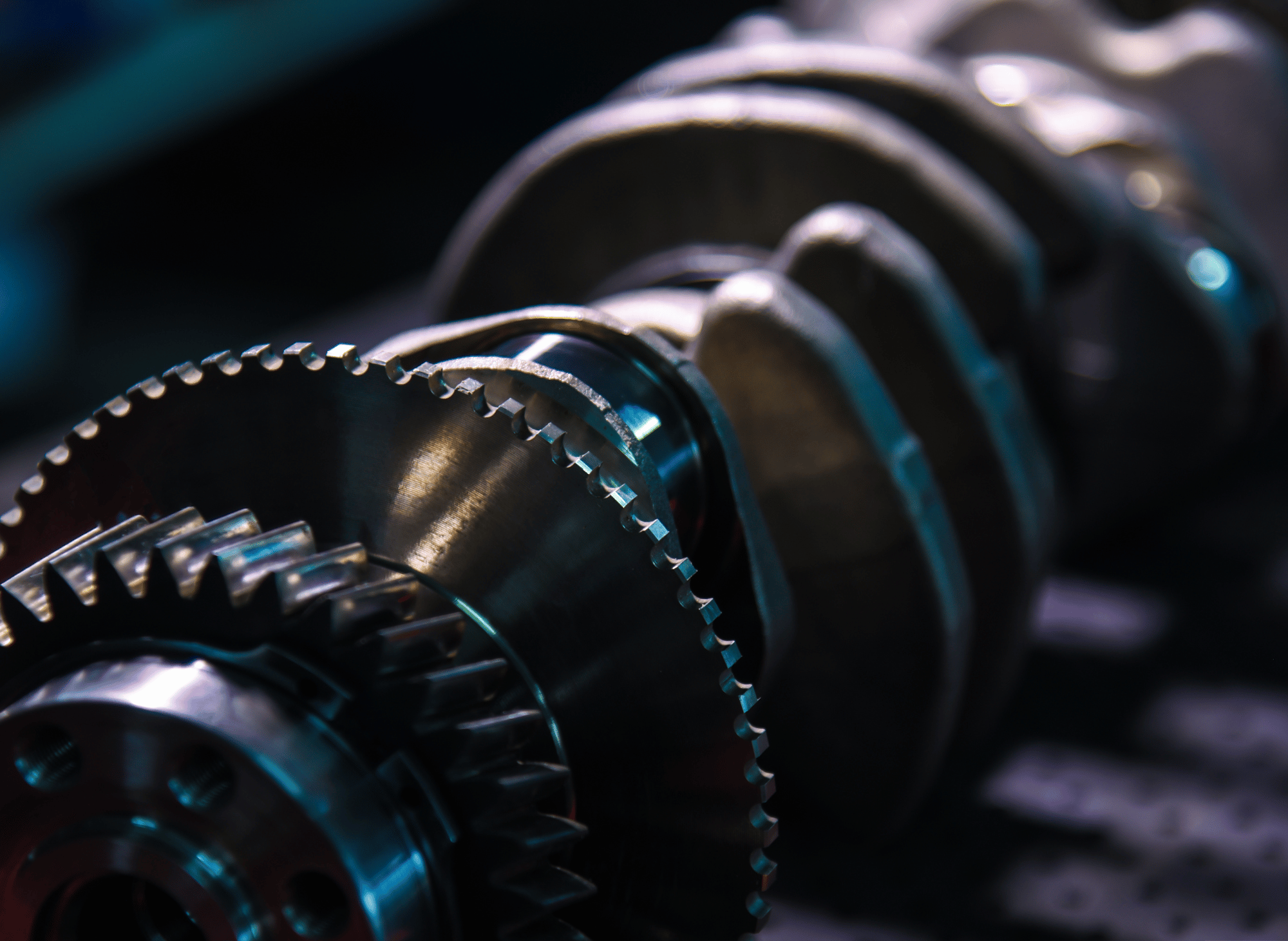

Crankshaft configurations are a cornerstone of engine design, directly influencing how an engine delivers power, manages vibration, and maintains long-term durability. The configuration refers to the specific arrangement of the crankshaft’s main bearings, crankpins, counterweights, and the way the connecting rod attaches to the crank. These design choices determine how efficiently the engine converts the piston’s linear motion into rotational force, and how well it withstands the intense stresses of high-performance operation.

One of the most common and effective designs in high-performance engines is the cross-plane crankshaft. In this configuration, the crankpins are set 90 degrees apart, creating a balanced firing order that significantly reduces vibration.

This smooth operation is essential for engines that need to maintain reliability and comfort at high RPMs, making cross-plane crankshafts a popular choice in powerful V8 engines. Forged crankshafts made from high-quality forged steel are often used in these applications, as they provide the strength and durability required to handle increased torque and power without compromising on efficiency.

Alternatively, the flat-plane crankshaft, with crankpins spaced 180 degrees apart, is favored in racing engines where maximum power and rapid throttle response are priorities. This configuration allows for higher engine speeds and a more aggressive exhaust note, but it can also introduce more vibration compared to the cross-plane design. The choice between these configurations depends on the desired balance between performance, smoothness, and engine character, which reflects on their sales in the market .

Main bearings play a critical role in supporting the crankshaft within the engine block. The number and location of these bearings are carefully chosen based on the engine’s design and the forces it must endure.

More main bearings generally mean greater stability and reduced vibration, which in turn enhances the crankshaft’s durability and the engine’s overall efficiency. High-quality main bearings are essential for protecting the crankshaft and ensuring smooth operation, especially in engines subjected to high loads.

The stroke of a crankshaft, the distance the piston travels from the top to the bottom of its cylinder, also has a profound impact on engine performance. Increasing the stroke, a process known as stroking, can boost low-end torque and improve drivability, but it may also increase vibration and place additional stress on the crankshaft and main bearings. Engine builders must carefully consider these implications when designing or upgrading a crankshaft to ensure the best balance of power, efficiency, and reliability.

Ultimately, selecting the right crankshaft configuration is about understanding the specific needs of your engine and application. Whether you require a forged crankshaft for maximum strength, a custom-machined design for unique performance goals, or a particular arrangement of main bearings and counterweights to reduce vibration, working with a reputable company that specializes in high-quality materials and precision machining is essential.

By making informed choices about crankshaft configurations, you can create an engine that delivers superior power, efficiency, and durability, ready to meet the demands of any performance challenge.

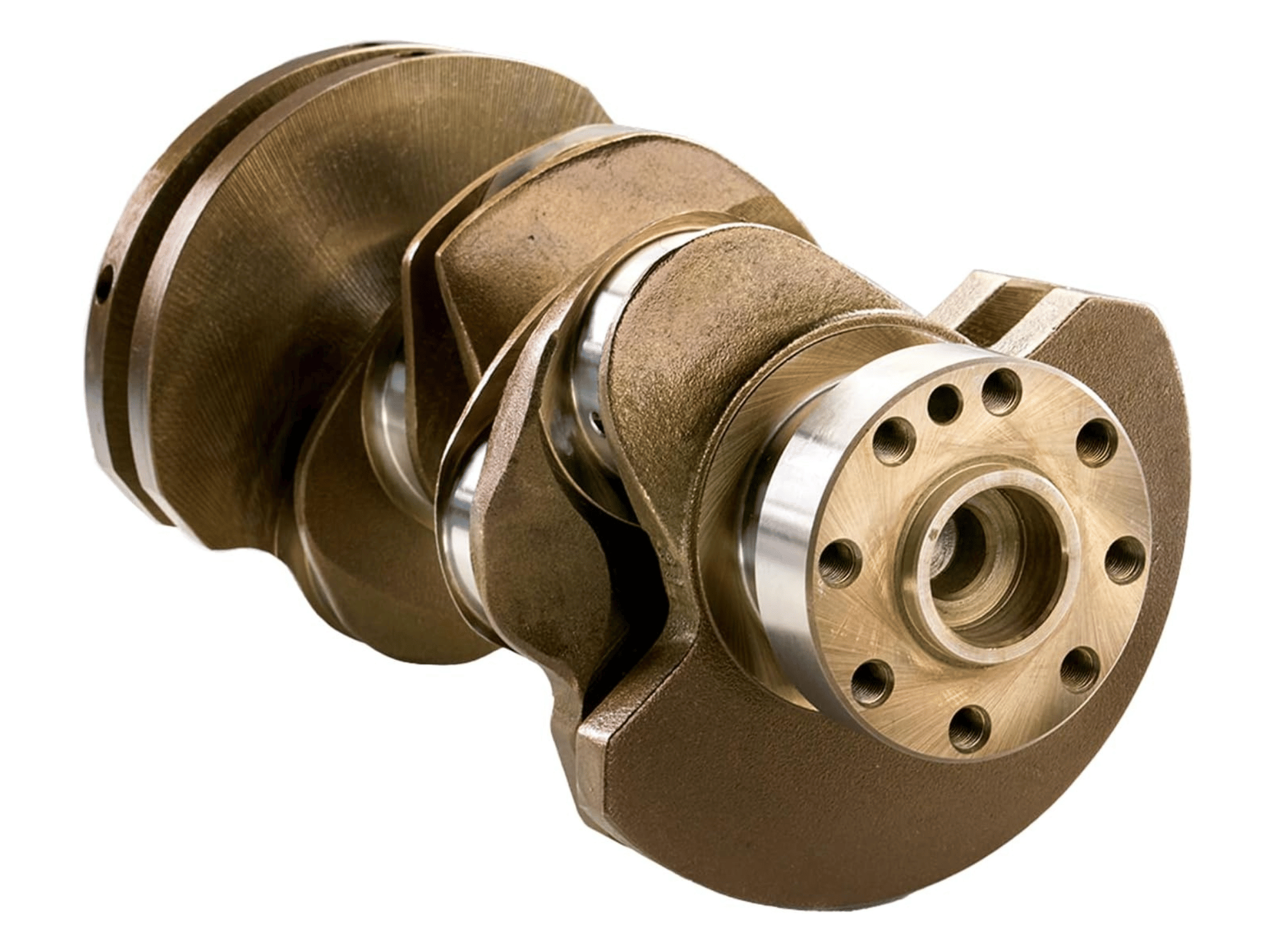

Materials Used in Crankshafts

The material used to construct a crankshaft is a primary determinant of its strength, durability, and performance under stress. Many crankshafts are manufactured in China, which is a leading hub for both OEM and aftermarket production. While standard crankshafts are typically made from cast iron or forged steel, recent news shows that high-performance models often utilize more advanced materials and manufacturing processes.

A leading example is the use of self-developed rare alloy casting. The specific content of the alloy directly impacts the crankshaft's performance, affecting durability and efficiency. This advanced material composition, combined with processes like multi-stage quenching and fillet rolling, results in a crankshaft with superior mechanical properties.

During these machining processes, metal chip is generated and must be managed to ensure high precision manufacturing. For instance, ZSTEM crankshafts made from this material can achieve a tensile strength of over 950MPa and a surface hardness (HRC) of 50. This makes them exceptionally resilient and suitable for high-load conditions found in performance-tuned engines.

Crankshafts are classified based on their material content, manufacturing process, and intended application, making it essential to search for the right type.

Performance Benefits of Upgrading to High-Performance Crankshafts

Swapping a stock crankshaft for a high-performance model isn’t just about replacing a part; it’s about upgrading the entire engine’s potential. The benefits are tangible and can be felt from the driver’s seat.

While high-performance crankshafts and their manufacturing processes can be expensive, many drivers find that the experience of driving with such upgrades justifies the investment.

Enhanced Engine Efficiency and Power

A high-performance crankshaft is lighter and stronger than its stock counterpart. This reduction in rotational mass allows the engine to rev more freely and quickly, improving throttle response.

You can find specific design features on common high-performance crankshafts, such as optimized oiling holes or radius fillets, that contribute to these efficiency and power gains. The superior strength ensures the crankshaft can handle increased power and torque from other engine modifications, such as turbochargers, superchargers, or high-compression pistons, without risking failure.

Improved Durability and Longevity

Performance engines operate under extreme stress. The high tensile strength and surface hardness of materials like rare alloy casting ensure that the crankshaft can withstand the immense forces of high-horsepower applications.

This enhanced durability translates to a longer service life, even under punishing race conditions or aggressive daily driving. Certifications like IATF 16949, an automotive-specific quality management standard, provide assurance to the automotive community that the component is manufactured to the highest quality and consistency standards.

Reduced Vibration and Noise

A key feature of premium crankshafts is high-precision dynamic balancing. During manufacturing, the crankshaft undergoes multiple balancing processes to ensure its mass is perfectly distributed around its rotational axis.

An imbalanced crankshaft will vibrate violently at high speeds, leading to excessive wear on bearings, creating uncomfortable driving conditions, and potentially causing catastrophic engine failure. A precisely balanced crankshaft, however, allows the engine to operate smoothly with minimal vibration and noise, even as it approaches its redline.

Types of High-Performance Crankshafts

High-performance crankshafts are not one-size-fits-all. They are designed for specific engines and vehicle applications. The design of mains (main bearing surfaces) is a key differentiator among various crankshaft types. Here are a few examples from ZSTEM’s lineup, showcasing the variety available for popular engine platforms.

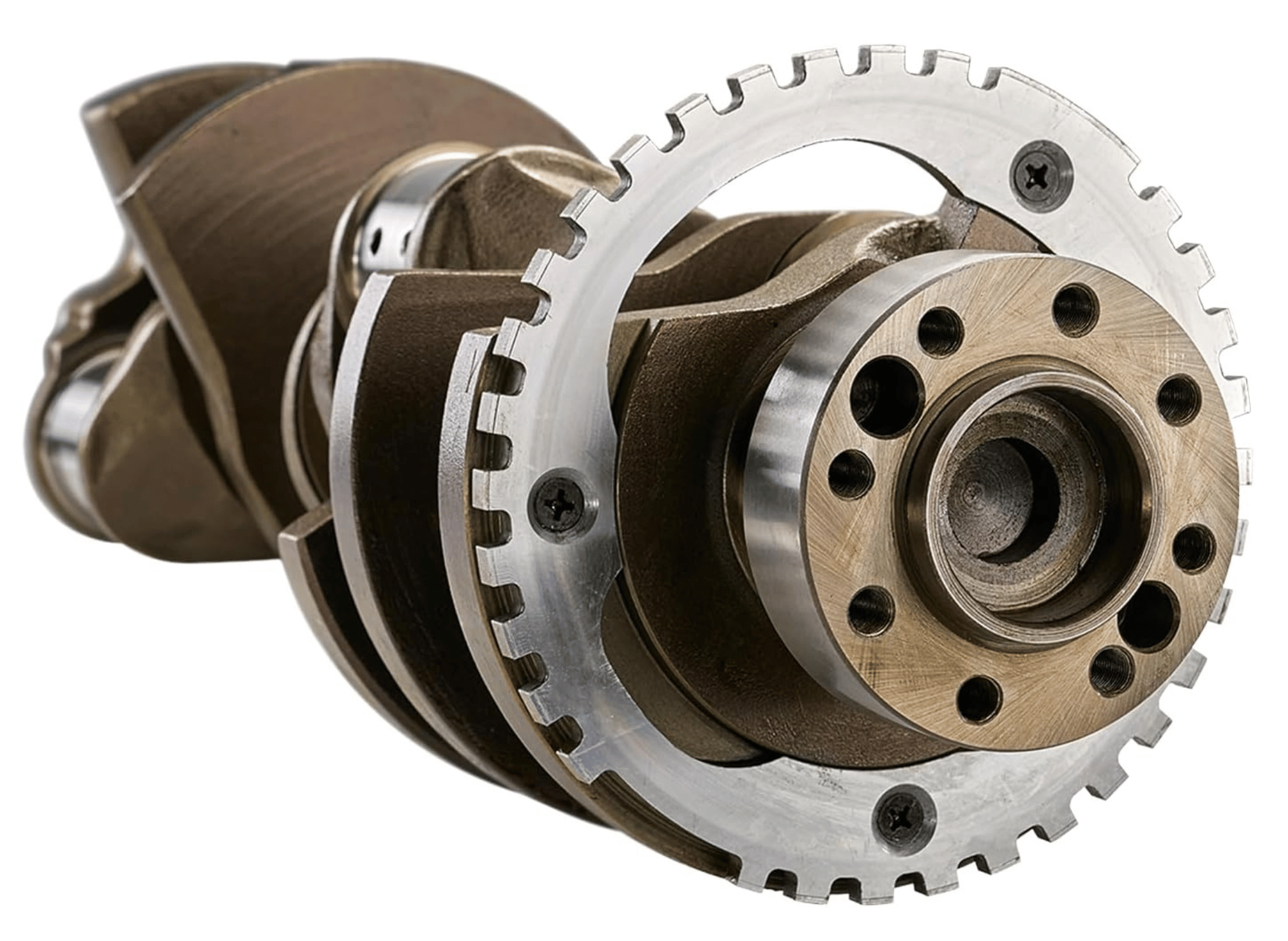

5.7 Hemi Crankshft w/Tone Ring

For Hemi 5.7L 345 V8 Engine Fit for Chrysler Dodge Challenger Durango Jeep Grand Cherokee Commander 5.7L 2009-2015,Replaces# 53021302AA,53021300AD, 53021300AA-ZSTEM

Hemi 5.7L V8 Crankshafts

The Chrysler Hemi 5.7L V8 is an iconic American engine found in a wide range of Dodge, Chrysler, and Jeep vehicles.

- Part Numbers: 53021300AA (for 31-tooth tone ring) and 53021300BB (for 58-tooth tone ring).

- Engine Code: Hemi 5.7 348 (5.7L) V8.

- Vehicle Fitment: Fits models like the 2005-2023 Chrysler 300, 2003-2025 Dodge Ram 1500, 2008-2023 Dodge Challenger R/T, and 2005-2022 Jeep Grand Cherokee. It's crucial to match the part number and tone ring tooth count to the specific model year.

VR30 ZSTEM New Upgraded Crankshaft

VR30 for Infiniti Q50 Q60 3.0L V6 2016-24 12201-5CA0A

Infiniti VR30 3.0L V6 Crankshaft

The Infiniti VR30DDTT is a modern twin-turbo V6 known for its impressive power potential.

- Part Number: 12201-5CA0A.

- Engine Code: VR30.

- Vehicle Fitment: Compatible with the 2016-2025 Infiniti Q50 and 2017-2025 Infiniti Q60. A performance crankshaft for this engine is key to reliably pushing boost levels beyond factory limits.

EcoBoost 3.5T Engine Crankshaft

Petrol V6 Compatible With 15-17 Ford F-150/Expedition/Navigator EcoBoost 3.5L AA5E817A

Ford EcoBoost 3.5L V6 Crankshaft

The Ford 3.5L EcoBoost engine is a workhorse, powering everything from the F-150 to the Taurus SHO.

- Part Number: AA5E817A.

- Engine Code: EcoBoost 3.5T.

- Vehicle Fitment: Fits the Ford F-150, Expedition, Explorer, and Taurus SHO. A robust crankshaft is vital for withstanding the high cylinder pressures of this turbocharged engine.

Other Notable Examples

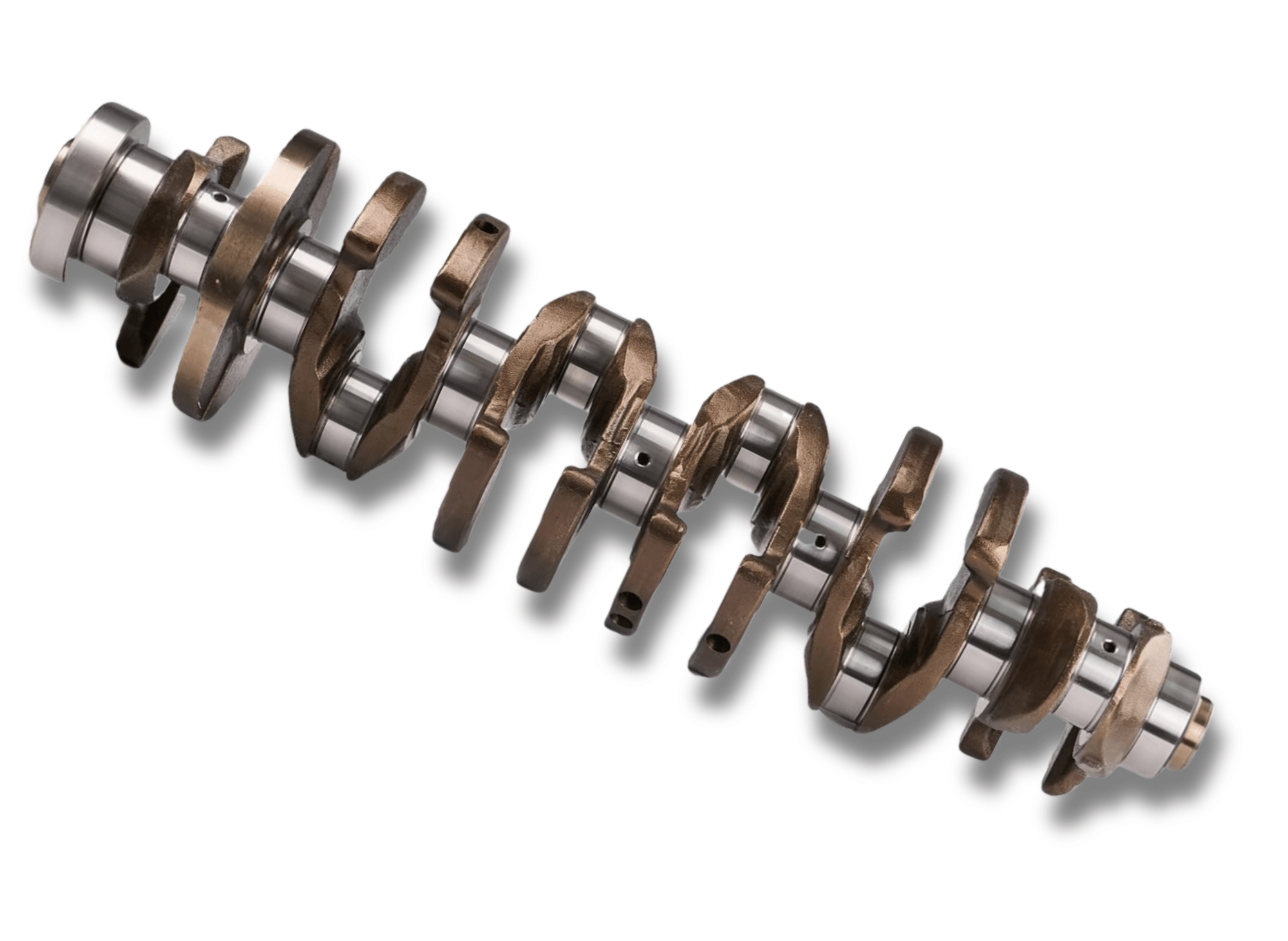

N54B30 N54 3.0 Engine Crankshaft

6 holes) Compatible For BMW 135i/335i/335is/535i/740i/X6/Z4/1 Series 11217599501

- BMW N54 3.0L I6: Part number 11217599501 for models like the 135i, 335i, and Z4.

F160 3.0 New Upgraded Engine Crankshaft

Fits for Maserati Quattroporte Levante Ghibli Ferrari 3.0L V6 323957 868821

- Maserati 3.0L Twin-Turbo V6: Part numbers 323957 / 868821 for the Ghibli, Quattroporte, and Levante.

TDV6 3.0L 306DT Engine Crankshaft

Compatible with 2009-2019 Land Rover Range Rover/Discovery V6 3.0L Diesel Engine 306 DT,for Jaguar XF/XJ/F-Pace (OE: LR038168)

- Land Rover/Jaguar 3.0L TDV6 Diesel: Part number LR038168 for the Range Rover, Discovery, and Jaguar F-Pace.

Selecting the Right Crankshaft

Choosing the correct crankshaft is critical for a successful engine build. An incorrect part can lead to improper fitment, poor performance, or severe engine damage.

To ensure you select the most appropriate crankshaft for your needs, consult with reputable manufacturers or suppliers for expert advice on material selection, quality, and customization options.

Key Factors to Consider

- Engine Code and Vehicle Compatibility: This is the most important factor. Always verify your vehicle's engine code and model year. Cross-reference this information with the crankshaft manufacturer's compatibility list. Part numbers are the most reliable way to ensure a match.

- Material and Manufacturing Quality: Look for crankshafts made from high-strength materials like forged steel or advanced rare alloy castings. Certifications like IATF 16949 are a strong indicator of a quality manufacturing process that adheres to strict automotive industry standards.

- Performance Needs: Are you building a daily driver with a modest power increase or an all-out race car? Your performance goals will influence your choice. For high-horsepower builds, a crankshaft with proven high tensile strength and superior dynamic balancing is non-negotiable.

Maintenance and Care

Once a high-performance crankshaft is installed, proper maintenance is key to ensuring its longevity.

- Use High-Quality Oil: Use the engine oil recommended by the manufacturer or a high-quality synthetic oil suitable for performance applications. Clean oil is essential for lubricating the main and rod bearings.

- Regular Oil Changes: Follow a strict oil change schedule. In performance applications, it's often wise to change the oil more frequently than the factory-recommended interval.

- Monitor Oil Pressure: Keep an eye on your oil pressure gauge. A sudden drop in pressure could indicate a problem with bearings or the oiling system that could damage the crankshaft.

- Professional Installation: Ensure the crankshaft is installed by a qualified mechanic. Proper bearing clearances, torque specifications, and assembly procedures are critical for the crankshaft's function and lifespan.

What Is the Difference Between Forged Crankshafts and an Alloy Casting Crankshaft?

The difference between a forged crankshaft and an alloy casting crankshaft lies in their manufacturing processes, material properties, and performance characteristics. Here's a breakdown:

1. Manufacturing Process

- Forged Crankshaft:

- Made by heating a solid piece of metal (usually steel or a steel alloy) and shaping it under high pressure using forging dies.

- The forging process aligns the grain structure of the metal, making it stronger and more durable.

- Alloy Casting Crankshaft:

- Made by pouring molten metal (often an alloy like cast iron or aluminum) into a mold to form the crankshaft.

- Casting allows for more complex shapes and is generally less expensive than forging.

2. Material Properties

- Forged Crankshaft:

- Denser and has a more uniform grain structure due to the forging process.

- Higher tensile strength and resistance to fatigue make it ideal for high-performance or heavy-duty applications.

- Alloy Casting Crankshaft:

- Typically, they are less dense and may have internal imperfections (like porosity) due to the casting process.

- Lower strength compared to forged crankshafts, but sufficient for standard or low-stress applications.

3. Performance

- Forged Crankshaft:

- Superior strength and durability make it suitable for high-performance engines, racing, or heavy-duty vehicles.

- Better at handling high loads, high RPMs, and extreme conditions.

- Alloy Casting Crankshaft:

- Adequate for everyday vehicles or applications where extreme performance is not required.

- Lighter and less expensive, but less capable of withstanding high stress or extreme conditions.

4. Cost

- Forged Crankshaft:

- More expensive due to the intensive manufacturing process and higher-quality materials.

- Alloy Casting Crankshaft:

- More cost-effective, making it a popular choice for mass-produced vehicles.

5. Applications

- Forged Crankshaft:

- Used in high-performance sports cars, heavy-duty trucks, and industrial engines.

- Alloy Casting Crankshaft:

- Common in standard passenger vehicles and applications where cost efficiency is a priority.

Summary

- Forged Crankshafts: Stronger, more durable, and better for high-stress applications, but more expensive.

- Alloy Casting Crankshafts: Cheaper, lighter, and suitable for standard applications, but less durable under extreme conditions.

The choice between the two depends on the engine's performance requirements and budget constraints.

What Does the Term Cross Plane Mean for a Crankshaft?

The term "cross-plane" in the context of a crankshaft refers to a specific configuration of the crankshaft's design, particularly in V8 engines. A cross-plane crankshaft has its crankpins arranged at 90-degree intervals, forming a "cross" shape when viewed from the end of the crankshaft. This design is distinct from a "flat-plane" crankshaft, where the crankpins are arranged in a flat, 180-degree configuration.

Key Characteristics of a Cross-Plane Crankshaft:

- Crankpin Arrangement: The crankpins are positioned at 90-degree angles relative to each other, creating a cross-like shape.

- Smooth Operation: The 90-degree arrangement helps balance the engine's primary and secondary forces, leading to smoother operation and reduced vibrations.

- Sound: Cross-plane crankshafts produce the characteristic deep, throaty exhaust note often associated with American V8 engines.

- Inertia: Cross-plane crankshafts tend to have higher rotational inertia due to their design, which can make them less responsive compared to flat-plane crankshafts.

Advantages:

- Better balance and reduced vibrations, making the engine smoother and more comfortable for everyday driving.

- Ideal for applications where smoothness and durability are prioritized, such as in muscle cars, trucks, and luxury vehicles.

Disadvantages:

- Heavier and more complex than flat-plane crankshafts.

- Higher rotational inertia can limit high-revving performance compared to flat-plane designs.

In summary, a cross-plane crankshaft is a design choice that prioritizes smoothness and balance, making it a popular option for many V8 engines, especially in American cars.

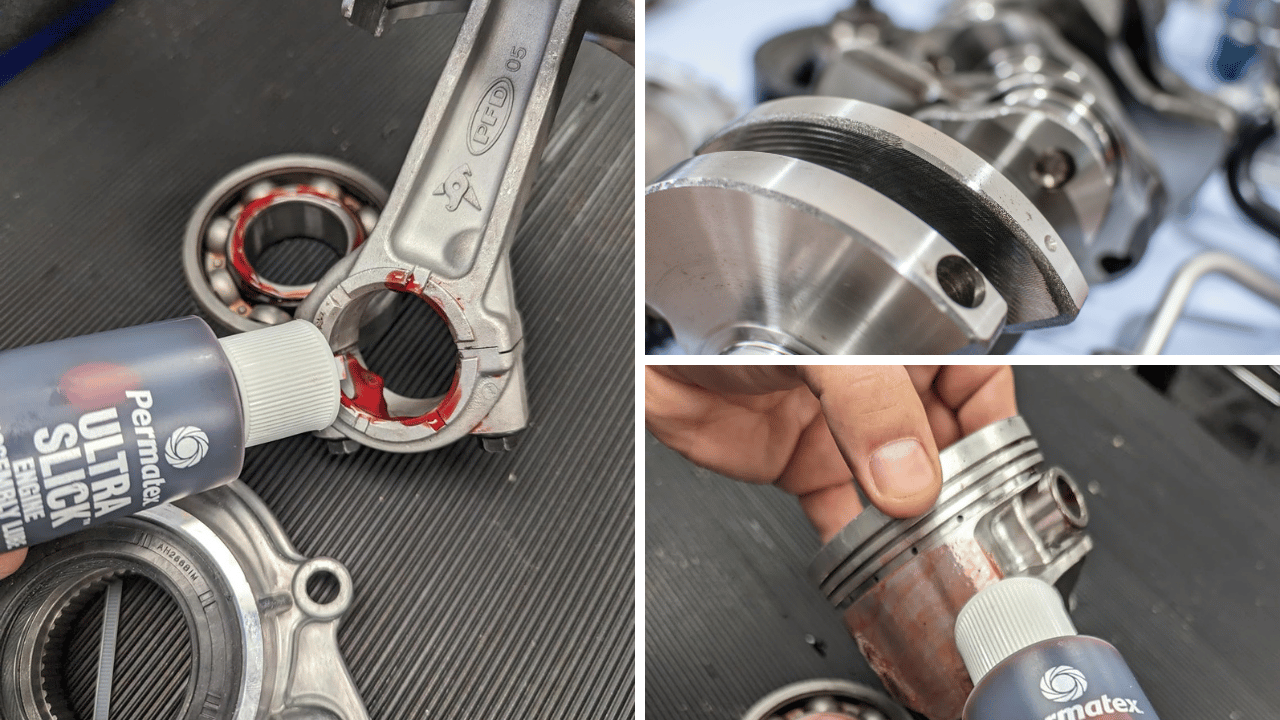

Is a Connecting Rod Made From Forged Steel?

Yes, connecting rods are often made from forged steel. Forged steel is a popular material for connecting rods because it offers high strength, durability, and resistance to fatigue, which are essential qualities for withstanding the intense forces and stresses experienced in an engine.

In high-performance or heavy-duty applications, forged steel connecting rods are preferred due to their superior mechanical properties compared to other materials like cast iron or aluminum. However, the specific material used can vary depending on the engine's design, performance requirements, and cost considerations.

Purchasing and Warranty Information

High-performance crankshafts from reputable brands like ZSTEM are available through online retailers like Amazon, often offering factory-direct pricing. When purchasing, always look for:

- A Comprehensive Warranty: A solid warranty demonstrates the manufacturer's confidence in their product. ZSTEM, for example, offers a one-year or 100,000-kilometer warranty on their crankshafts, along with a claim of a very low breakage rate of less than 0.01%.

- Clear Return Policies: A clear and fair return policy provides peace of mind in case you order the wrong part or encounter any issues.

- Seller Reputation: Purchase from the official brand store or a trusted distributor to ensure you are receiving a genuine, high-quality product.

Unleash Your Engine's True Potential

The crankshaft is more than just a piece of metal; it is the central pillar of your engine's performance. Upgrading to a high-performance crankshaft made from superior materials and manufactured to exacting standards is one of the most effective ways to build a powerful, reliable, and smooth-running engine. By enhancing durability, increasing power-handling capabilities, and reducing harmful vibrations, a high-performance crankshaft lays the foundation for you to push your vehicle to its limits.

For those in the automotive community, whether professional mechanics or passionate enthusiasts, investing in a quality crankshaft is an investment in the heart of your machine. ZStem Crankshafts, known for their precision engineering and premium accessories, offer a range of options designed to meet the demands of high-performance engines. Their commitment to quality ensures that every crankshaft is built to deliver exceptional results, no matter how hard you push your vehicle.

To learn more about ZStem Crankshafts and their accessories, visit their website and view the full range of products available. Creating a high-performance engine starts with choosing the right components, and ZStem makes it easy to continue your journey toward peak performance. Agreeing to invest in a superior crankshaft is not just a decision; it's a commitment to excellence and reliability.

If you're ready to take your engine to the next level, visit the ZStem page today. Explore their offerings, view detailed specifications, and discover why so many in the automotive world trust ZStem for their performance needs. Your engine deserves the best, and with ZStem Crankshafts, you can ensure it gets exactly that.

Thanks for stopping by

Your friend

Todd

#ZStemCrankshafts! 💪⚙️ #PrecisionEngineering #HighPerformance #EnginePower #CrankshaftTech #BuiltToLast #AutoInnovation #RacingReady #EngineUpgrade #CarEnthusiast 🚗🏁🔧🔥🚀"

Amazon Prime offers a wide range of products designed to cater to diverse customer needs, all with the added benefit of fast, reliable delivery. From household essentials and groceries to electronics, clothing, and entertainment, Prime members get access to exclusive deals and discounts across various categories.

Additionally, Prime membership includes access to services like Prime Video for streaming movies and TV shows, Amazon Music for ad-free music, and Prime Reading for eBooks and magazines. This comprehensive suite of benefits makes Amazon Prime a convenient and value-packed option for millions of customers worldwide.

- Prime for you, adult

- Free 30-day trial of Prime

- All of Prime, half the price.

- Prime Video

- Wedding Registry

- Kindle Unlimited

- Amazon Music