The Ultimate Rivet Nut Tool Guide for DIY & Mechanics

A rivet nut tool enables you to install a threaded insert, also known as a rivet nut, into a pre-drilled hole.

Welcome to Mechanicaddicts. As an Amazon Associate, we earn from qualifying purchases (at no cost to you) from links found within these pages if you choose to buy something.

If you’ve ever needed to create a strong, threaded anchor point in thin metal, plastic, or fiberglass, you know how tricky it can be. Traditional methods, such as welding a nut, are often impractical, especially for DIY enthusiasts or mechanics working in tight spaces.

This is where a rivnut tool, also known as a rivet nut tool or nutsert tool, becomes an indispensable part of your toolkit. Rivet nut tool kits often come with a variety of different sizes and accessories, making them versatile for a range of projects.

This connection creates a secure and reliable threaded socket where you can attach bolts and other components. It’s a clean, efficient solution for everything from custom car modifications and boat repairs to assembling furniture and installing roof racks.

For anyone who works with metal fabrication or frequently needs to create load-bearing attachment points in thin materials, a rivet nut tool is a game-changer. This guide will walk you through everything you need to know, from the various types of tools available to selecting and using the right one for your projects.

We’ll also compare some of the most popular models on the market to help you make an informed decision. Be cautious of cheap tools that may fail during use—investing in quality ensures success, durability, and reliability.

When sourcing rivet nut tools and accessories, McMaster-Carr is a complete source with a large plant and extensive stock for quick delivery, making it a reliable option for all your project needs.

What is a Rivet Nut Tool and Why is it Useful for Threaded Inserts?

A rivet nut is a one-piece, internally threaded insert. When you use a rivet nut tool, it compresses and deforms the nut on the “blind” side of the material, creating a permanent, bulged flange that locks it firmly in place. This provides a clean, strong thread, ready for a bolt. Rivet nuts are a type of blind rivet fastener used to create strong threaded connections in thin sheet metal and other materials.

The primary advantage is the ability to install threads in materials that are too thin to be tapped for a traditional screw or bolt. Think of it as adding a permanent nut to a piece of sheet metal under pressure, where you can’t easily reach the back side to tighten the fastener.

The key benefits include those that contribute to your success :

- Versatility: They work on a wide range of materials, including steel, aluminum, plastic, and composites.

- Strength: Rivet nuts provide a high-strength, load-bearing thread that resists pull-out.

- Effectiveness: Rivet nut tools are highly effective at providing secure, reliable threads in a variety of materials.

- Convenience: Installation is quick and can be done from one side of the workpiece, making it ideal for closed-off sections, such as tubing or box frames.

- Clean Finish: It provides a professional and flush finish without the need for welding or other complex fastening methods.

A fine rivet nut tool, manufactured to high standards, provides the necessary support and ensures consistent results. Using a good tool, along with a wrench, makes installation easier and works great for both professionals and happy DIYers.

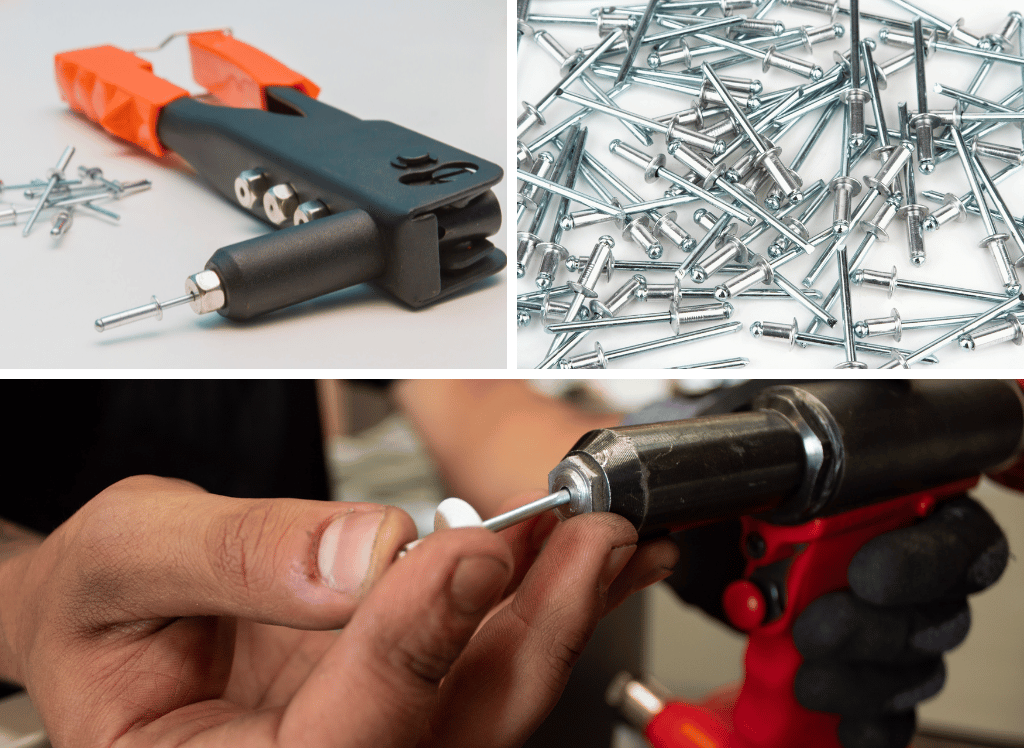

Types of Rivet Nut Tools: Hand vs. Pneumatic

Rivet nut tools generally fall into two categories: manual (hand-operated) and pneumatic (air-powered). Many of these tools feature interchangeable heads, allowing users to easily switch between different sizes for various applications.

When installing rivet nuts, it is important to ensure that the holes in the sheet metal or panel are properly sized and placed to achieve a secure fit and prevent damage. High-quality rivet nut tools can often be repaired, which extends their lifespan and makes them a cost-effective investment.

These tools can be purchased from reputable suppliers, ensuring that products ordered ship on time, and some users may choose to sell their tools after completing a project.

As an alternative to rivet nut tools, a stud and washers can be used for mounting or securing components, providing a simple and effective DIY solution in certain situations. Rivet nuts were originally sold under the RIVNUT® trademark and are now widely available from various brands.

Hand Rivet Nut Tools

Manual tools are the most common choice for DIYers, home workshops, and mechanics who need portability. They operate using a lever or a squeeze mechanism that provides the mechanical advantage needed to set the rivet nut. When installing a rivet nut manually, a wrench can be used to hold the bolt head in place to prevent it from spinning while tightening the fastener.

- Plier-Style Tools: These are smaller and best suited for smaller rivet nuts (typically up to M6 or 1/4-20). They are lightweight and easy to use for light-duty applications, but require more hand strength for larger nuts.

- Lever-Style Tools: These tools, often featuring long handles (14-16 inches or more), provide significantly more leverage. This makes them ideal for setting larger and more robust rivet nuts (M8, M10, M12, and larger SAE sizes) with less physical effort. Most of the popular consumer kits fall into this category.

Pros:

- Affordable and widely available.

- Portable and doesn’t require an air compressor.

- Excellent for occasional use and on-the-go repairs.

Cons:

- Requires physical effort, which can be fatiguing for repetitive tasks, and significant time is spent when manually installing multiple rivet nuts.

- Slower than pneumatic tools for high-volume work.

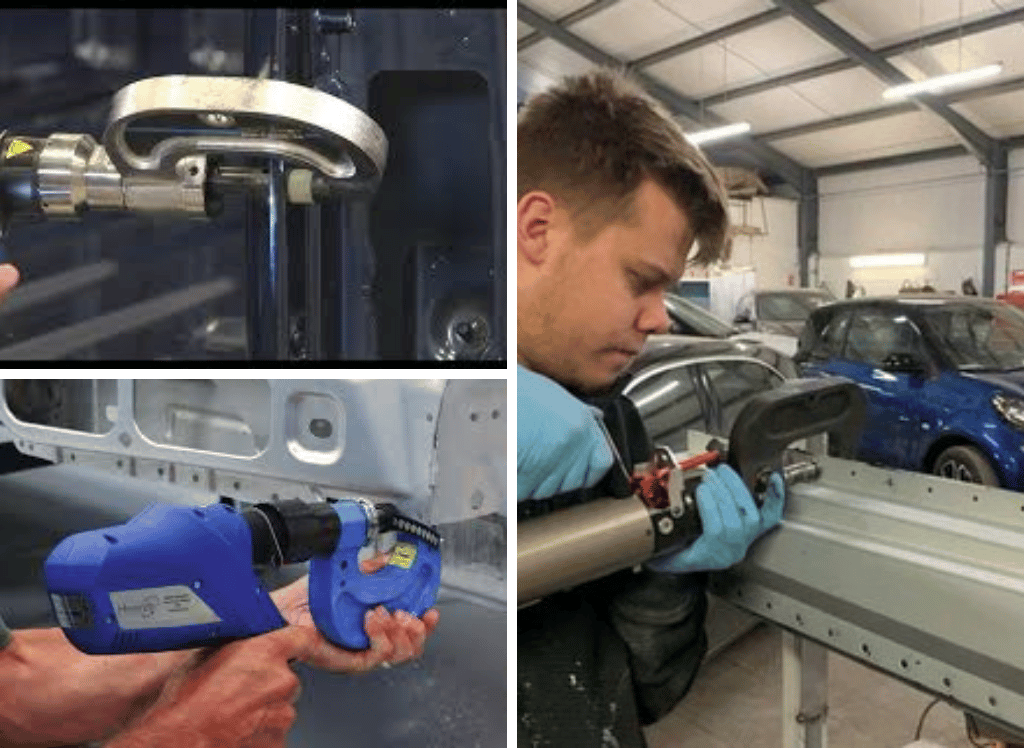

Pneumatic (Air) Rivet Nut Tools

Pneumatic tools use compressed air to do the hard work of setting the rivet nut. With the press of a trigger, the tool pulls the mandrel and sets the nut in seconds. These are the go-to support tools for professional manufacturing, assembly lines, and high-volume repair shops. Pneumatic tools are known for their effectiveness in ensuring secure and precise installations. A good example is the UPWOOD Heavy Duty Air Hydraulic Rivet Nut Tool.

Pros:

- Extremely fast and efficient for repetitive tasks.

- Pneumatic tools deliver fast and consistent results, making them ideal for high-volume work.

- Requires minimal physical effort from the operator.

- Provides a consistent and reliable setting force.

Cons:

- Significantly more expensive than manual tools.

- Requires an air compressor, limiting portability.

- It can be overkill for the average DIY enthusiast.

In summary, a fine pneumatic tool can make a significant difference in professional settings, offering both speed and effectiveness for demanding applications.

Key Features to Look For in a Rivet Nut Tool

When shopping for a rivet nut tool, several features will determine its performance, durability, and ease of use.

- Material and Build Quality: Look for tools made from high-strength materials, such as heat-treated carbon steel or chromium steel. A robust build ensures the tool can withstand the high forces required to set rivet nuts without flexing or breaking. A fine tool, manufactured by reputable companies, ensures durability and reliability. A quality oil-resistant handle coating, such as TPR soft rubber, can also enhance grip and comfort.

- Effort-Saving Design: For manual tools, longer handles (16 inches is a good length) provide better leverage and reduce the effort needed. Some models, like the NOVORIK tool, feature an internal lever system specifically designed to multiply your force, making the job easier on your muscles.

- Mandrel Sizes and Compatibility: A good kit will come with a wide range of interchangeable mandrels to fit various rivet nut sizes, including both metric (M3, M4, M5, etc.) and SAE (10-24, 1/4-20, etc.) standards. The more mandrels included, the more versatile the tool. Some tools also feature interchangeable heads, allowing you to quickly adapt the tool for different applications and nut sizes, increasing versatility and convenience.

- Tool-Free Mandrel Changes: The ability to swap mandrels without needing extra wrenches is a considerable convenience. This feature, found on tools like the NOVORIK model, saves time and frustration, especially when you’re switching between different nut sizes on a single project.

- Value for Money: Investing in a good tool can save you money in the long run by reducing the need for replacements and ensuring reliable performance.

Safety Precautions When Using Rivet Nut Tools

When working with rivet nut tools, safety should always be a top priority to ensure both a successful installation and your personal well-being. Always wear safety glasses to protect your eyes from flying debris, and gloves to shield your hands from sharp edges on rivet nuts or sheet metal. Before starting any installation, inspect your tool for signs of wear or damage. Loose parts or worn mandrels can cause the nut to spin or the tool to slip, increasing the risk of injury.

Make sure your work area is clear and well-lit, and keep bystanders at a safe distance. Avoid applying excessive force during installation, as this can cause the rivet nut to spin in the hole or damage the threads. Always follow the manufacturer’s instructions for your specific tool and regularly maintain it by cleaning and lubricating moving parts. By taking these precautions, you’ll minimize the risk of accidents and ensure your rivet nut tool delivers reliable, safe results every time.

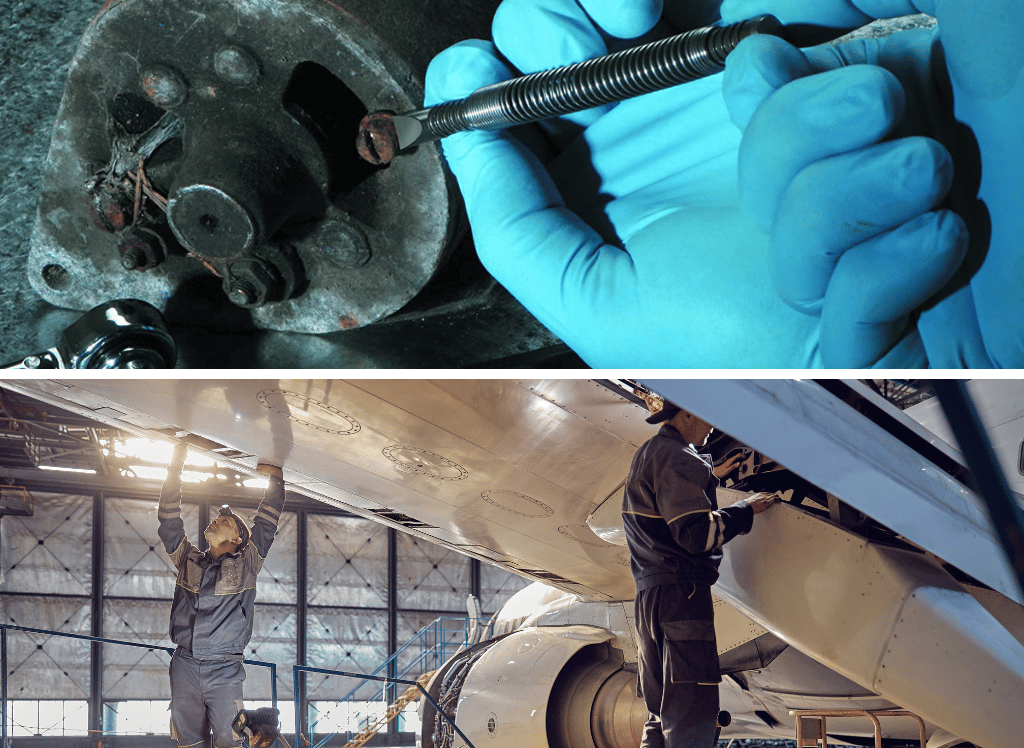

Common Applications for Rivet Nut Tools

Rivet nut tools are incredibly versatile and find their place in a wide range of industries and DIY projects. In automotive repair and customization, they’re essential for installing threaded inserts in thin sheet metal, such as body panels, chassis components, and roof racks, where access to the back side is limited.

In construction and manufacturing, rivet nut tools are used to fasten materials like steel, aluminum, and plastic, making them ideal for assembling machinery, equipment, and even factory support structures. For DIY enthusiasts, these tools are perfect for building furniture, installing shelving, or repairing appliances—anywhere you need a strong, reliable thread in thin materials.

Rivet nut tools also excel at installing blind rivets and other fasteners, including bolt connections, in roofing, siding, and decking, providing a secure hold without the need for welding or tapping. Whether you’re working with sheet metal, composites, or plastics, rivet nut tools offer a clean, efficient fastening method that stands up to repeated use.

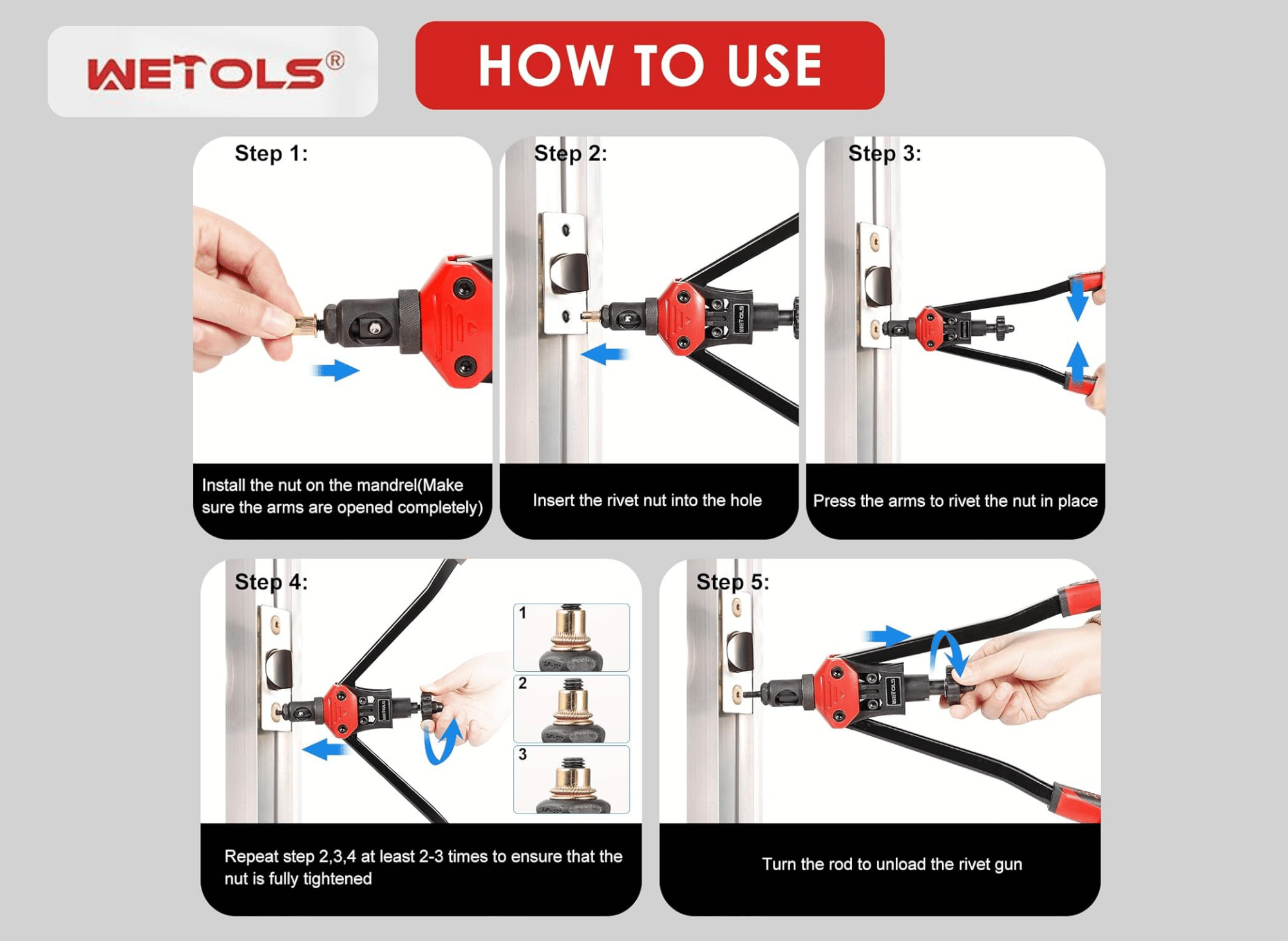

How to Use a Rivet Nut Tool: A Step-by-Step Guide

Using a rivet nut tool is straightforward once you get the hang of it. Here’s a general process for a manual lever-style tool, which you can see demonstrated in this video :

- Drill the Hole: Start by drilling a clean, correctly sized hole in your workpiece. The rivet nut should fit snugly but not require force to insert. Check the rivet nut manufacturer’s specifications for the exact drill bit size. Make sure the holes are the correct diameter to ensure a secure fit and prevent damage to the panel.

- Select the Right Mandrel: Choose the mandrel and nosepiece that match the size and thread of your rivet nut. Attach it securely to the tool.

- Thread the Rivet Nut: Screw the rivet nut onto the mandrel until it is flush with the end of the nosepiece.

- Insert into the Workpiece: Insert the rivet nut into the pre-drilled hole. Ensure the flange of the nut is sitting flush against the surface of the material.

- Set the Rivet Nut: Squeeze the handles of the tool together firmly. You will feel the tool pulling the mandrel, which compresses the body of the rivet nut on the other side. Continue squeezing until the handles come to a firm stop. This indicates the nut is fully set. If you are using a bolt and nut method, use a wrench to hold the bolt head steady to prevent it from spinning during installation.

- Release the Tool: Once the nut is set, unscrew the mandrel from the newly installed insert. On some tools, you turn a knob to release it; on others with an “auto-release” feature, simply pulling the handles apart may initiate the release.

- Inspect Your Work: You should now have a secure fastener and a threaded insert ready for your bolt.

Tips:

- Using washers, such as fender washers, can help distribute the load and prevent damage to thin materials during installation.

- In some cases, a stud with washers and nuts can be used as an alternative installation method to specialized rivet nut tools.

- For visual learners, helpful videos are available online that demonstrate the rivet nut installation process step by step.

- The amount of time or effort spent on installation can be reduced with practice and by using the right tools.

Essential Accessories for Rivet Nut Tools

To get the best performance from your rivet nut tool, having the right accessories is key. A high-quality mandrel is essential for delivering the torque needed to install rivet nuts securely, and having a variety of mandrels on hand ensures you can tackle different nut sizes and thread types.

Wrenches and sockets are useful for tightening or removing nuts and washers, while a thread tap can help clean up threads for a perfect fit during installation. A well-organized kit, complete with a range of rivet nuts and mandrels, makes it easy to handle any job, whether you’re working on a DIY project or a professional repair.

Consider investing in a sturdy carrying case or storage box to keep your tools and accessories protected and easy to find. With the right accessories, you’ll be ready for any installation challenge, ensuring your rivet nut tool delivers strong, reliable threads every time.

Comparing Popular Rivet Nut Tools

Let’s look at some popular models available on the market to see how they stack up. These rivet nut tools can be purchased from various retailers, including online stores and local hardware shops.

Many users report that these tools work great for installing rivnuts in different materials and sizes, highlighting their effectiveness and fine quality. Some happy customers mention that after completing their projects, they choose to sell their tools to recoup some of their investment.

When considering price and value, it's important to avoid cheap, low-quality options that may lead to costly failures. Investing a bit more money in a reliable, high-quality tool can save you money in the long run by reducing the risk of problems and ensuring that products ordered ship efficiently.

Additionally, some of these factory tools can be repaired if they become worn or damaged, thereby extending their useful life and increasing their overall value.

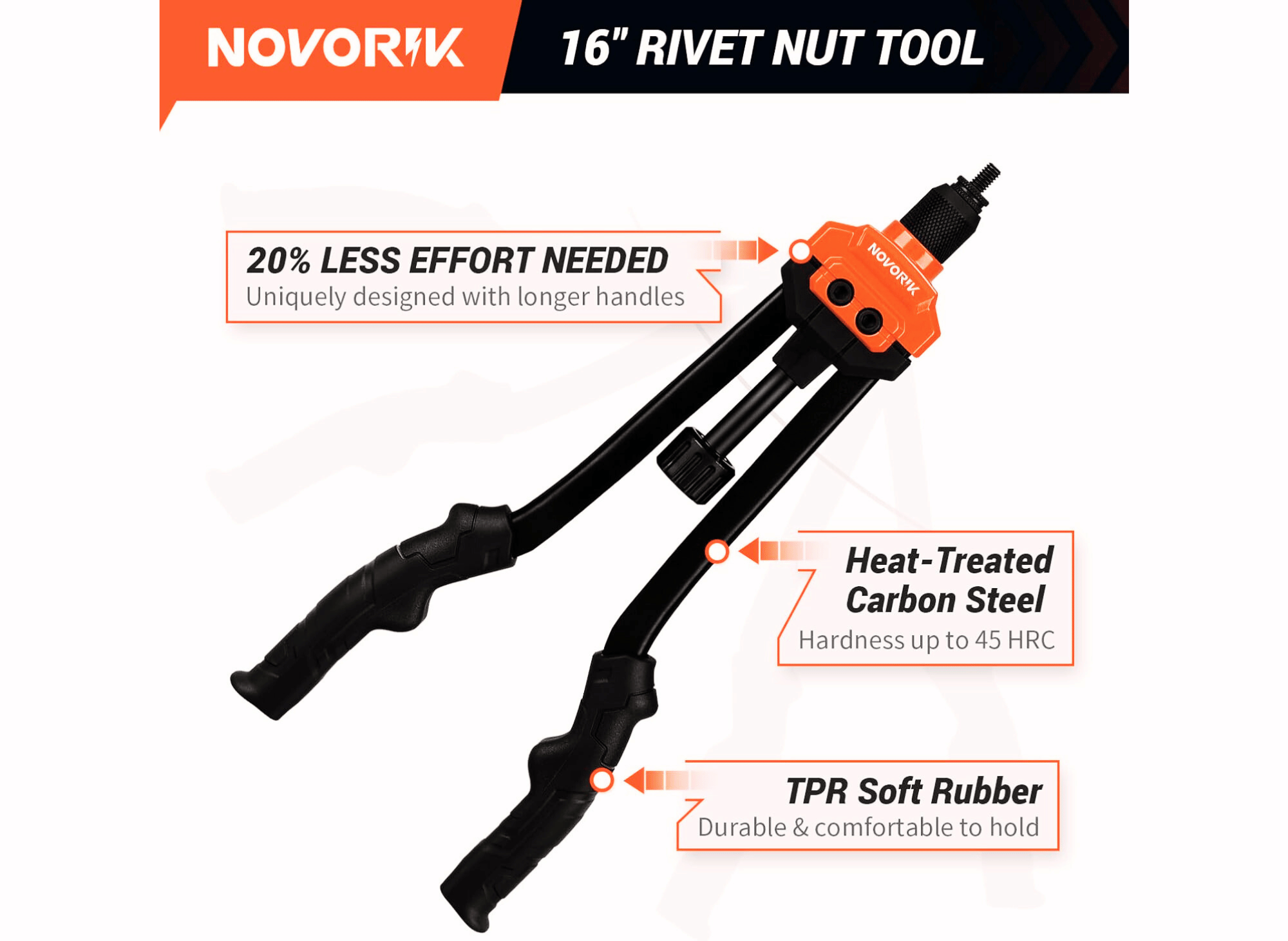

NOVORIK Rivet Nut Tool

16” RIV Nut Tool Kit with 15 Metric & SAE Mandrels, 182pcs Rivnuts Nutserts Kit and Rugged Carrying Case, One Rivnut Tool Kit Meet All Your Needs

NOVORIK 16” Rivet Nut Tool Kit

- Overview: This comprehensive kit is designed for both DIY enthusiasts and professionals. Its 16-inch handles and internal lever system are built to reduce user effort.

- Features: It boasts an impressive 15 metric and SAE mandrels, covering almost any size you’ll encounter. The standout feature is its tool-free, quick-change system for mandrels. The kit includes a bunch of mandrels and rivet nuts, providing versatility for a wide range of applications. Interchangeable heads allow you to easily switch between different sizes, making the tool adaptable for various tasks.

- Build: Made with a chromium steel core and reinforced carbon steel handles.

- Customer Feedback: With a 4.6-star rating, users praise its sturdy construction, ease of use, and the wide assortment of mandrels and included rivet nuts (182 pieces).

- Price: Around $68, it offers excellent value for a complete and versatile kit. This kit is often in stock at major suppliers, ensuring quick availability for your projects.

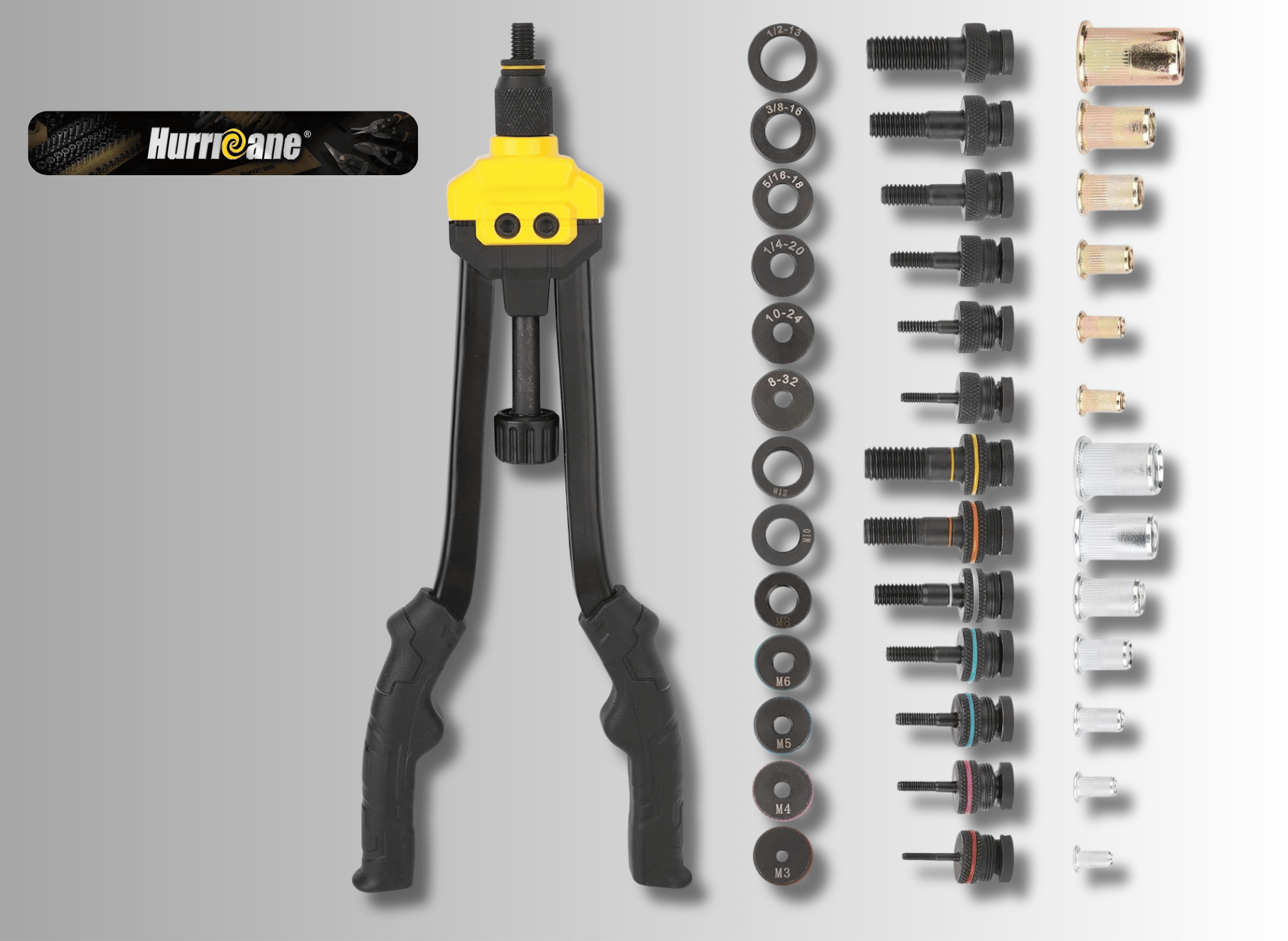

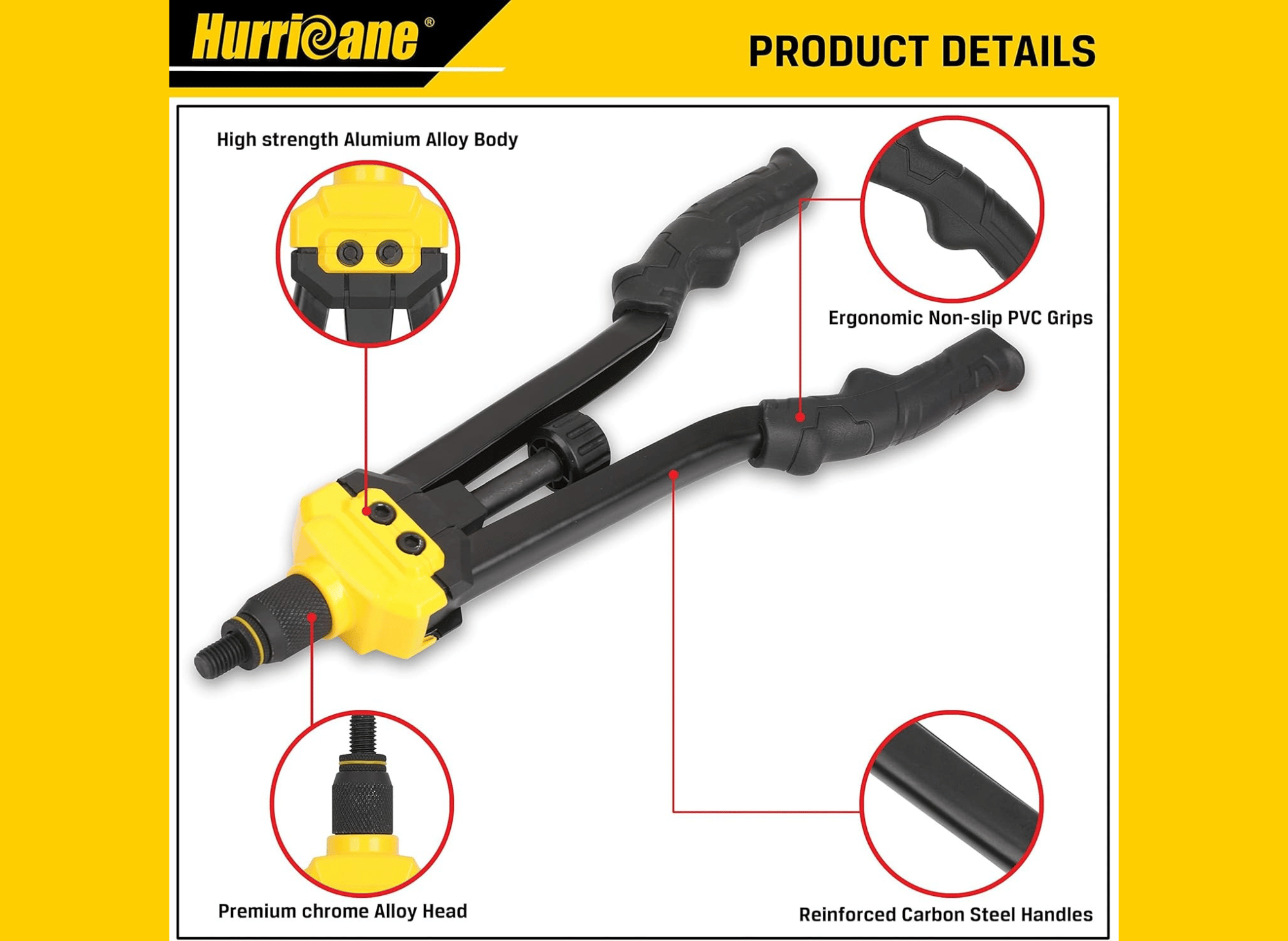

HURRICANE 16” Rivet Nut Tool

Hand Rivet Nut Tool with 13 Metric and SAE Mandrels, 130Pcs Threaded Rivet Nuts, Auto Release Nutsert Rivnut Tool, Durable Riveter Nutsert Hand Tool, Sturdy Plastic Case

HURRICANE 16” Rivet Nut Tool

- Overview: Similar in design to the NOVORIK, this 16-inch lever tool is another strong contender for heavy-duty use.

- Features: It includes 13 metric and SAE mandrels and 130 rivet nuts. A key feature is its “auto-release” nut design, which simplifies the process of unscrewing the tool after setting the nut.

- Customer Feedback: Users appreciate its durability and the leverage provided by the long handles, making it suitable for larger nuts. Many also note the effectiveness of the tool in setting larger nuts quickly and securely, even in tougher materials.

- Price: Priced around $45, it’s a very cheap option for a 16-inch tool, but it still offers fine build quality compared to other budget models.

WETOLS 16" Rivet Nut Tool

Professional Rivet Nut Tool Kit with 11 Metric & Inch Mandrels M3 M4 M5 M6 M8 M10 M12, 10-24, 1/4-20, 5/16-18, 3/8-16, 110pcs Rivnuts and Blow Carry Case - WE-889

WETOLS 16” Rivet Nut Tool Kit

- Overview: As a #1 Best Seller on Amazon, the WETOLS tool has proven its popularity. Many users have purchased this kit for its value, noting that it offers a reliable solution without spending extra money on professional installation. Its slightly shorter 14-inch frame makes it a bit more compact.

- Features: The kit includes 7 of the most common metric and SAE mandrels and 70 rivet nuts. While it has fewer mandrels than the 16-inch kits, it covers the basics for most projects.

- Customer Feedback: With over 6,500 ratings, it’s a crowd favorite. Users say it works great, praising its solid performance and reliability for the price. Some note that it requires more effort for larger nuts compared to 16-inch models.

- Price: Often available for around $40, it’s an unbeatable entry-level option that can save you money compared to more expensive kits or hiring a professional.

AOBEN 16" Rivet Nut Tool

Professional Hand Rivet Nut Setter Kit with 12 Interchangeable Metric & SAE Mandrels, 145 Pcs Rivnuts and Rugged Carrying Case

AOBEN Rivet Nut Tool Kit

- Overview: The AOBEN kit is another well-regarded tool known for its solid build and upgraded design. The tool can also be repaired if needed, which helps maintain its durability and cost-efficiency.

- Features: It comes with 10 metric and SAE mandrels and 100 rivet nuts. It’s a balanced kit that bridges the gap between basic and fully comprehensive sets.

- Customer Feedback: With over 2,100 ratings, customers find it to be a fine quality, reliable, and robust tool. It’s often praised for its effectiveness, feeling sturdy, and performing consistently.

- Price: At around $70, it sits at the higher end of the manual tool market, competing with models like the NOVORIK.

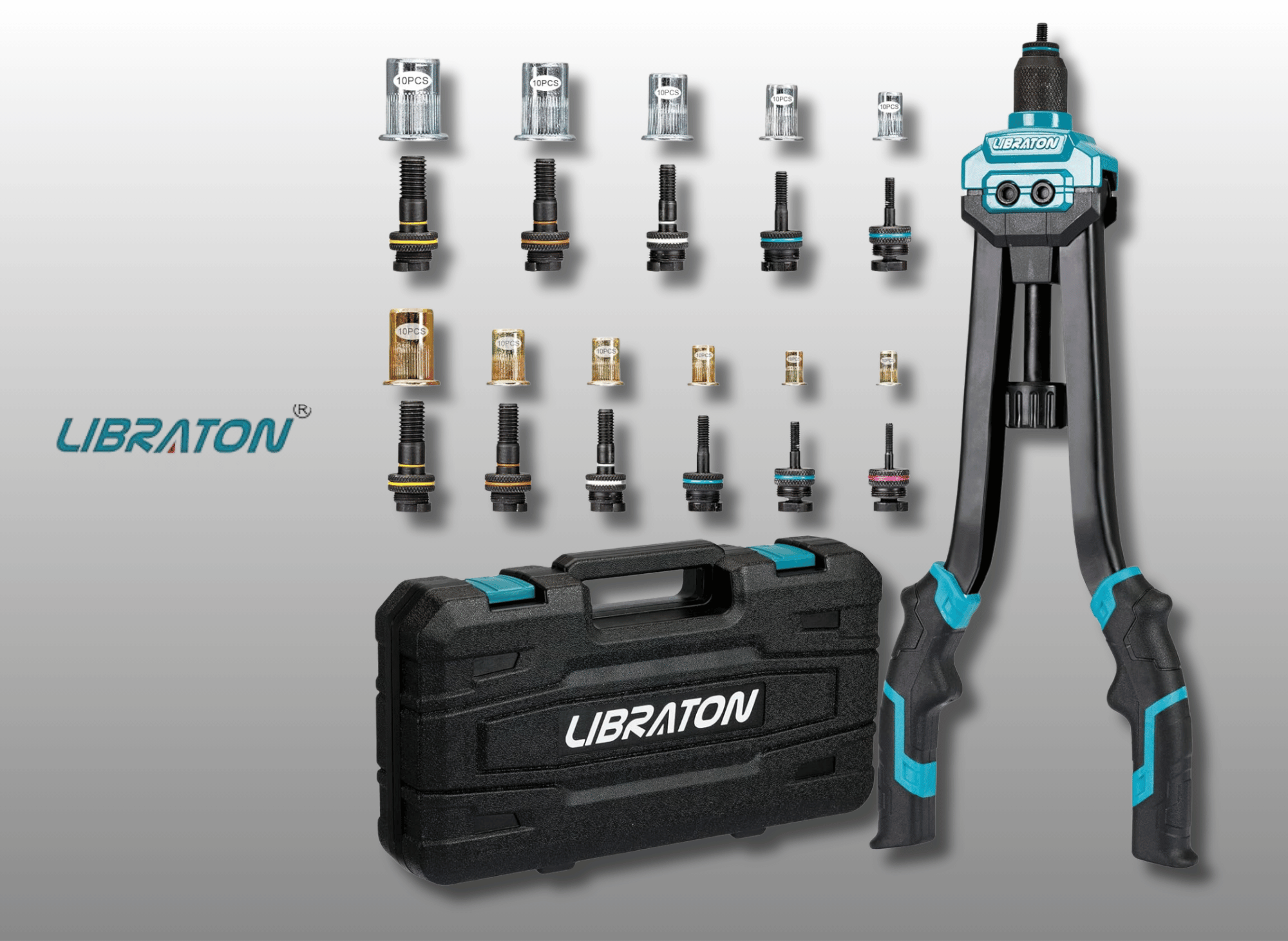

LIBRATON 16" Rivet Nut Tool

Rivet Nut Gun, Hand Rivet Nut Setter with 110 PCS Rivet Nuts, 11PCS Metric & SAE Interchangeable Mandrels and Carrying Case, Easy Replace

LIBRATON 16” Rivet Nut Tool

- Overview: The LIBRATON tool offers a similar 16-inch design with a focus on durability and user convenience.

- Features: This kit includes 11 mandrels and 110 rivet nuts. It also features interchangeable heads that can be easily swapped for different applications, along with an auto-release design to speed up workflow.

- Customer Feedback: Though it has fewer ratings, feedback is positive, highlighting its solid construction and smooth operation.

- Price and Availability: Priced around $73, it’s another premium manual option. This tool is often in stock and available for quick shipping.

- Summary: Suppliers with a large plant can provide this tool efficiently, ensuring reliable access for industrial or manufacturing needs.

Troubleshooting Common Rivnut Tool Issues

Even the best rivet nut tools can encounter issues from time to time, but most problems are easy to fix with a little troubleshooting. If you notice the rivet nut spinning in the hole or not installing properly, check the mandrel for damage or looseness, tighten or replace it as needed. Insufficient torque or pressure can also lead to poor installation; make sure your tool’s settings are correct and that you’re applying a steady, even force.

If your tool becomes stuck or jammed, clean and lubricate the moving parts to restore smooth operation. Always ensure the rivet nut is properly aligned with the hole before installation, and that the work surface is clean and free of debris. For persistent issues, consult the manufacturer’s instructions or seek professional repair. By addressing these common problems promptly, you’ll keep your rivet nut tool in top condition and ensure every nut is installed securely.

Maintenance and Care for Your Tool

To ensure your rivet nut tool lasts for years and helps you save money in the long run, choose tools that can be easily repaired and maintained. Investing in a repairable tool means you avoid unnecessary replacements and get more value for your money.

Follow these simple maintenance tips:

- Keep it Clean: Wipe down the tool after each use to remove dirt and debris.

- Lubricate Moving Parts: Regularly apply a light machine oil to the pivot points, hinges, and the threads of the mandrels. This ensures smooth operation and prevents rust.

- Inspect Mandrels: Before each use, check the mandrels for any signs of wear, especially on the threads. A damaged mandrel can strip the threads of the rivet nut or the tool itself. Replace or have them repaired as needed to prolong tool life.

- Store Properly: Keep your tool and its accessories in its carrying case. This protects it from moisture and damage and keeps all the small parts organized.

The time spent on regular care and maintenance is worthwhile, as it extends the lifespan of your tool and reduces the money you might otherwise spend on replacements or professional repairs.

Understanding Industry Standards for Rivet Nut Tools

When choosing rivet nut tools, it’s essential to consider industry standards that ensure quality, safety, and reliability in the quantity you require. Look for tools that meet ISO 9001 certification, which ensures consistent manufacturing quality and reliability. Compliance with safety standards from organizations like OSHA and ANSI is also crucial, especially for tools used in industrial or commercial settings.

Standards set by the Society of Automotive Engineers (SAE) and the American Society of Mechanical Engineers (ASME) help ensure that your rivet nut tools and accessories are compatible with a wide range of fasteners and materials.

Reputable suppliers such as McMaster-Carr and Rivet Nut USA offer factory products that meet or exceed these standards, providing excellent support and giving you confidence in your purchase. By selecting rivet nut tools that adhere to recognized industry benchmarks, you can be sure you’re investing in tools that are safe, durable, and effective for any job.

Your Next Steps to Riveting Success

Choosing the right rivet nut tool depends on your specific needs and budget. When considering your options, don’t forget the value of quality and repairability. Relying on a cheap tool may seem like a way to save money upfront.

- For the Occasional DIYer: If you only need to set smaller rivet nuts occasionally, a budget-friendly and popular model like the WETOLS 16” Rivet Nut Tool is an excellent starting point. Many users have purchased this tool for small projects and found it reliable for the price.

- For the Serious Enthusiast or Mechanic: If you plan to work with a wide range of nut sizes, including larger, high-strength ones, investing in a 16-inch tool is well worth it. The NOVORIK 16” Rivet Nut Tool stands out for its extensive mandrel set and tool-free change system, offering professional-grade versatility. The HURRICANE 16” Tool is an excellent alternative if you’re on a tighter budget but still want the power of a longer-handled tool. Remember, spending a bit more money on a quality tool can save you from costly issues down the road.

- For High-Volume Professional Use: If you’re setting hundreds of nuts a day, the speed and low effort of a pneumatic tool like the UPWOOD Air Hydraulic Riveter will pay for itself in time and labor savings.

No matter which tool you choose, mastering the use of a rivet nut tool will open up new possibilities for your projects, allowing you to create strong, professional connections with bolt applications in materials where it was once difficult or impossible. Many users who have purchased high-quality tools find that they can sell them after completing their projects, recouping some of their investment and saving even more money in the long run.

Thank you for reading!

Your friend,

Todd

#RivetNutTool #DIYTools #ToolboxEssentials #FixItFast #HandyTools #ToolTime #DIYProjects #BuiltToLast #ToolLovers #RivetReady

🔧✨ Perfect for DIYers! 💪🛠️ No more loose ends! 🪛🔩 Get the job done right! ✅⚙️ Your toolbox MVP! 🏆🧰

Amazon Prime offers a wide range of products designed to cater to diverse customer needs, all with the added benefit of fast, reliable delivery. From household essentials and groceries to electronics, clothing, and entertainment, Prime members get access to exclusive deals and discounts across various categories.

Additionally, Prime membership includes access to services like Prime Video for streaming movies and TV shows, Amazon Music for ad-free music, and Prime Reading for eBooks and magazines. This comprehensive suite of benefits makes Amazon Prime a convenient and value-packed option for millions of customers worldwide.

- Prime for you, adult

- Free 30-day trial of Prime

- All of Prime, half the price.

- Prime Video

- Wedding Registry

- Kindle Unlimited

- Amazon Music