BILITOOLS Valve Spring Compressor Tools In A Complete Kit

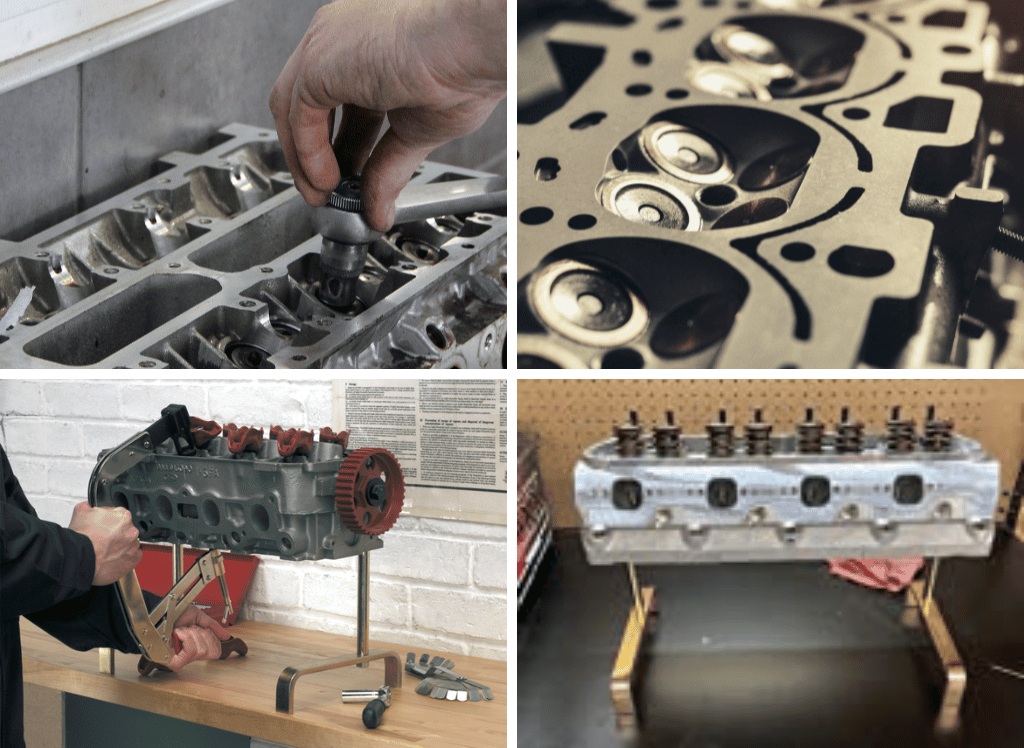

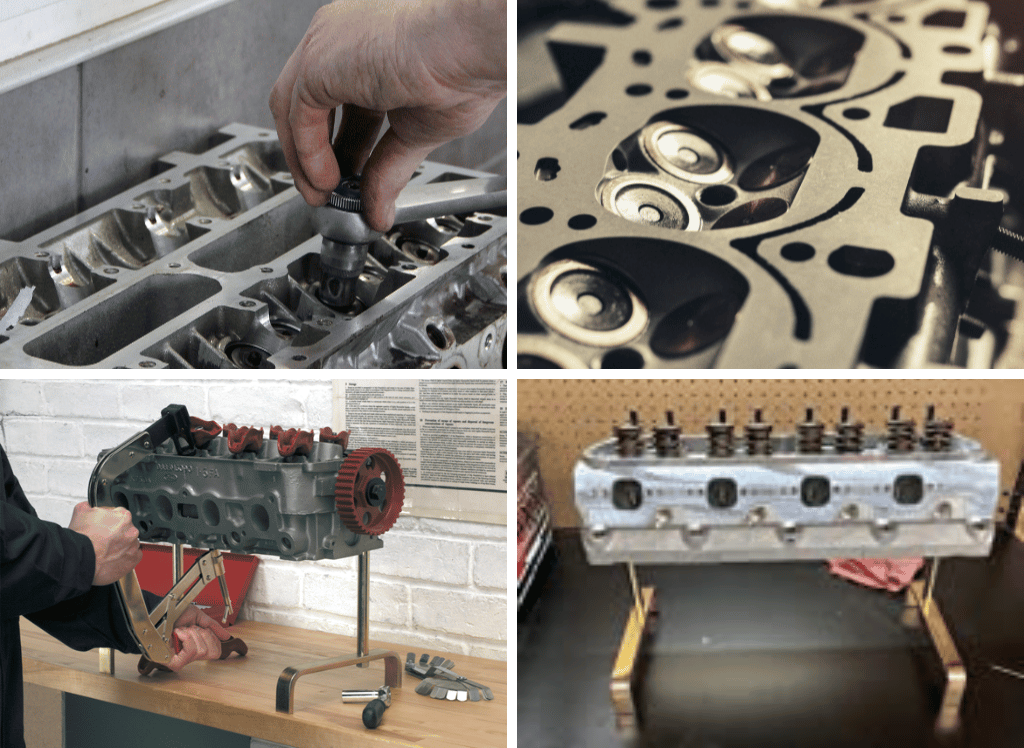

These specialized devices allow you to safely remove and install valve springs during engine rebuilds, valve replacements, and cylinder head work.

Welcome to Mechanicaddicts. As an Amazon Associate, we earn from qualifying purchases (at no cost to you) from links found within these pages if you choose to buy something.

Engine maintenance requires precision tools, and valve spring compressor tools stand among the most critical equipment in any mechanic’s arsenal. These tools are essential for car and truck maintenance and are specifically designed for automotive applications to simplify the process. Without the right compressor tool, what should be a routine maintenance task becomes nearly impossible or, at best, a dangerously improvised solution.

Whether you’re a seasoned automotive professional or a dedicated DIY enthusiast, understanding valve spring compressor tools will save you time, money, and frustration. The right tool makes the job easy and fast, even for those working on cars at home. There are various types of valve spring compressor tools available. This guide covers everything from tool selection to proper usage techniques, helping you choose the right equipment and use it safely and effectively.

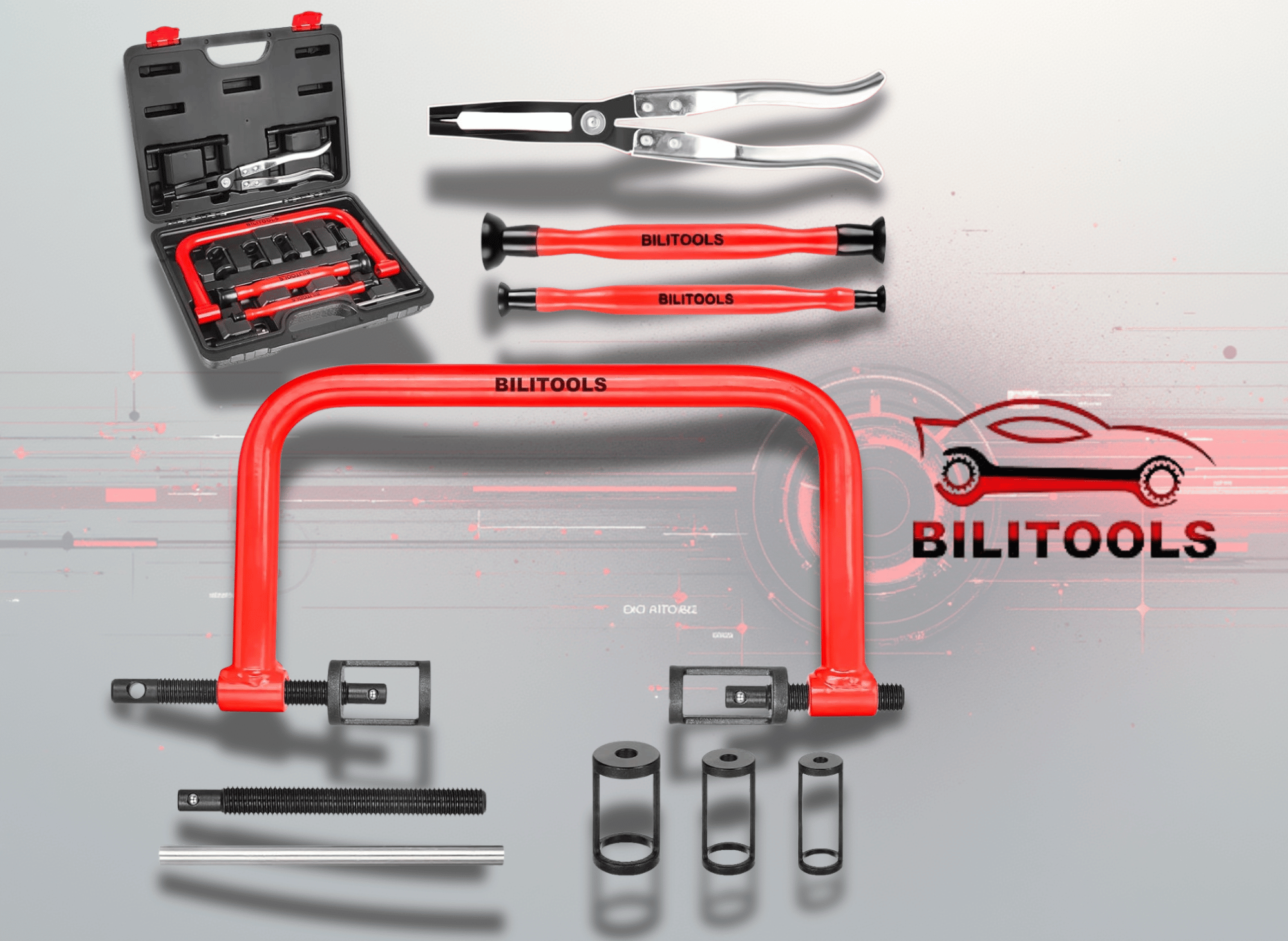

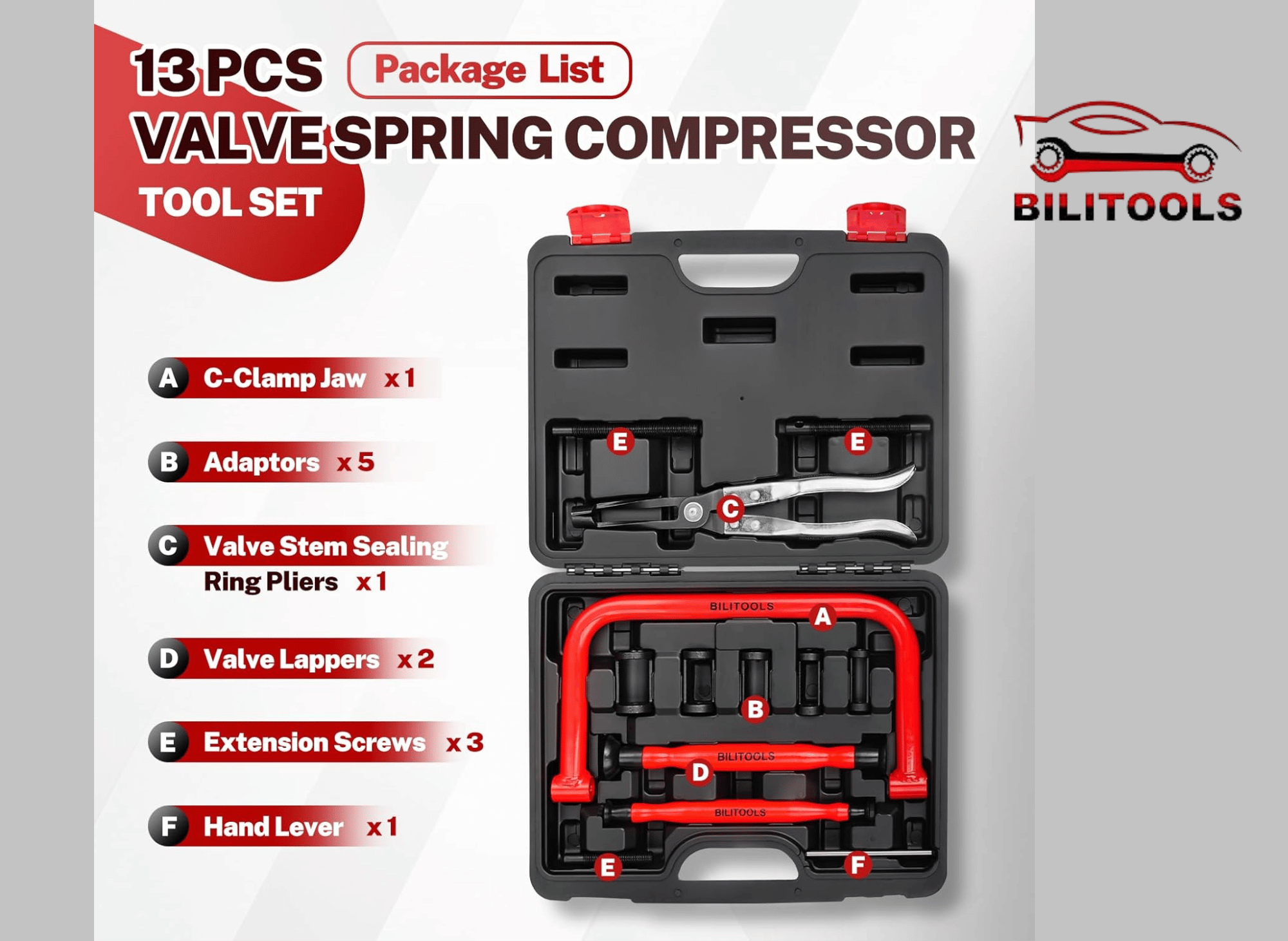

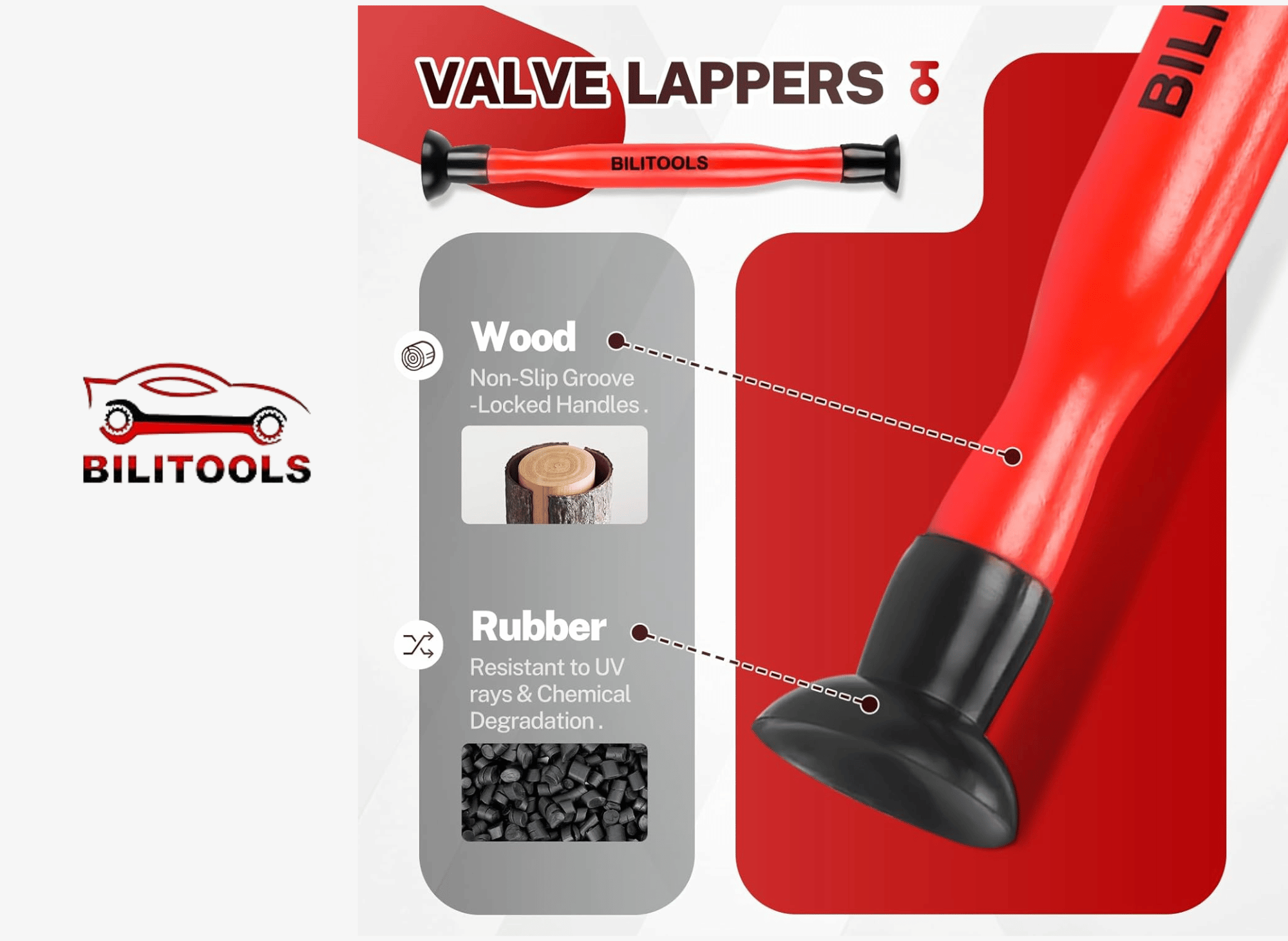

BILITOOLS 13pcs Valve Spring Compressor Tools

With Straight Valve Stem Seal Plier, Valve Lapping/Grinding Tool

Types of Valve Spring Compressor Tools

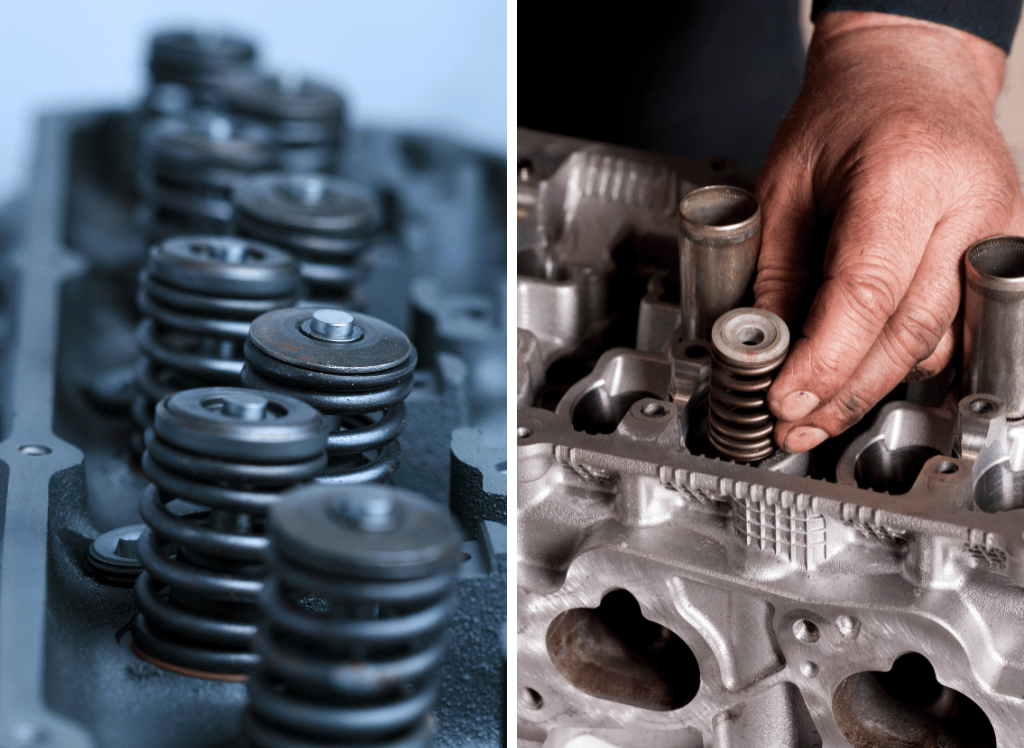

Valve spring compressor tools come in several distinct configurations, each designed for specific applications and engine types. To effectively use each kind of tool, it's essential to measure how each compresses the valve springs in a slightly different way depending on its design.

Overhead Valve Spring Compressors

Overhead valve compressors operate directly on engines with the cylinder head still in place. These tools feature a lever-action design that allows mechanics to compress big springs while the head remains in position. Most overhead compressors include multiple adapter pieces to accommodate different valve configurations and cylinder heads.

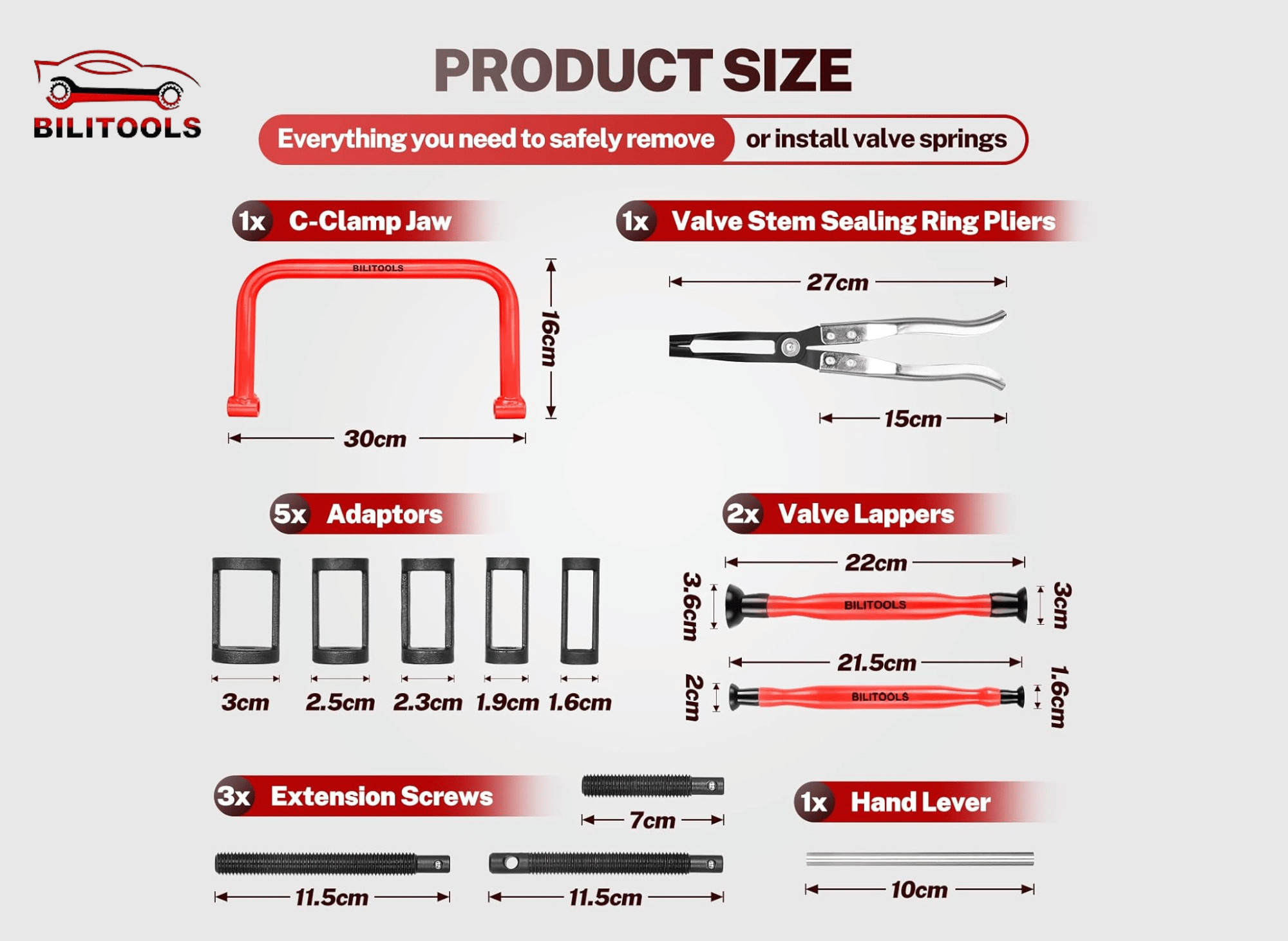

The BILITOOLS 13-piece kit exemplifies this category, offering comprehensive compatibility with most automotive and small engine valve springs. These tools typically include hand levers, C-clamp jaws, extension screws, and various pusher adapters to handle different vehicle valve arrangements.

Bench-Mounted Valve Spring Compressors

Bench-mounted tools require removing the cylinder head from the engine before use. These compressors offer superior control and leverage, making them ideal for saving time in heavy-duty applications or when working on multiple heads simultaneously, ensuring the job is done efficiently. Professional shops often prefer bench-mounted units for their stability and consistent results, making them a good choice for high-quality engine work.

Universal Valve Spring Compressors

Universal compressors bridge the gap between specialized and general-purpose tools. The SMOTIVEPRO Universal Automotive Engine Valve Spring Removal Tool effectively represents this category, offering broad compatibility across various engine types. Universal tools sacrifice some specialized features for versatility, making them excellent choices for mechanics who need to work efficiently on diverse vehicle fleets.

Engine-specific compressors provide the most precise fit for particular applications. The Orion Motor Tech LS Valve Spring Compressor Tool exemplifies this approach, specifically designed for LS1, LS2, LS3, LS6, and related General Motors engines. While these tools offer superior performance in their intended applications, they lack the versatility needed to remove various types of valve springs, such as universal designs.

Factors to Consider When Choosing a Tool

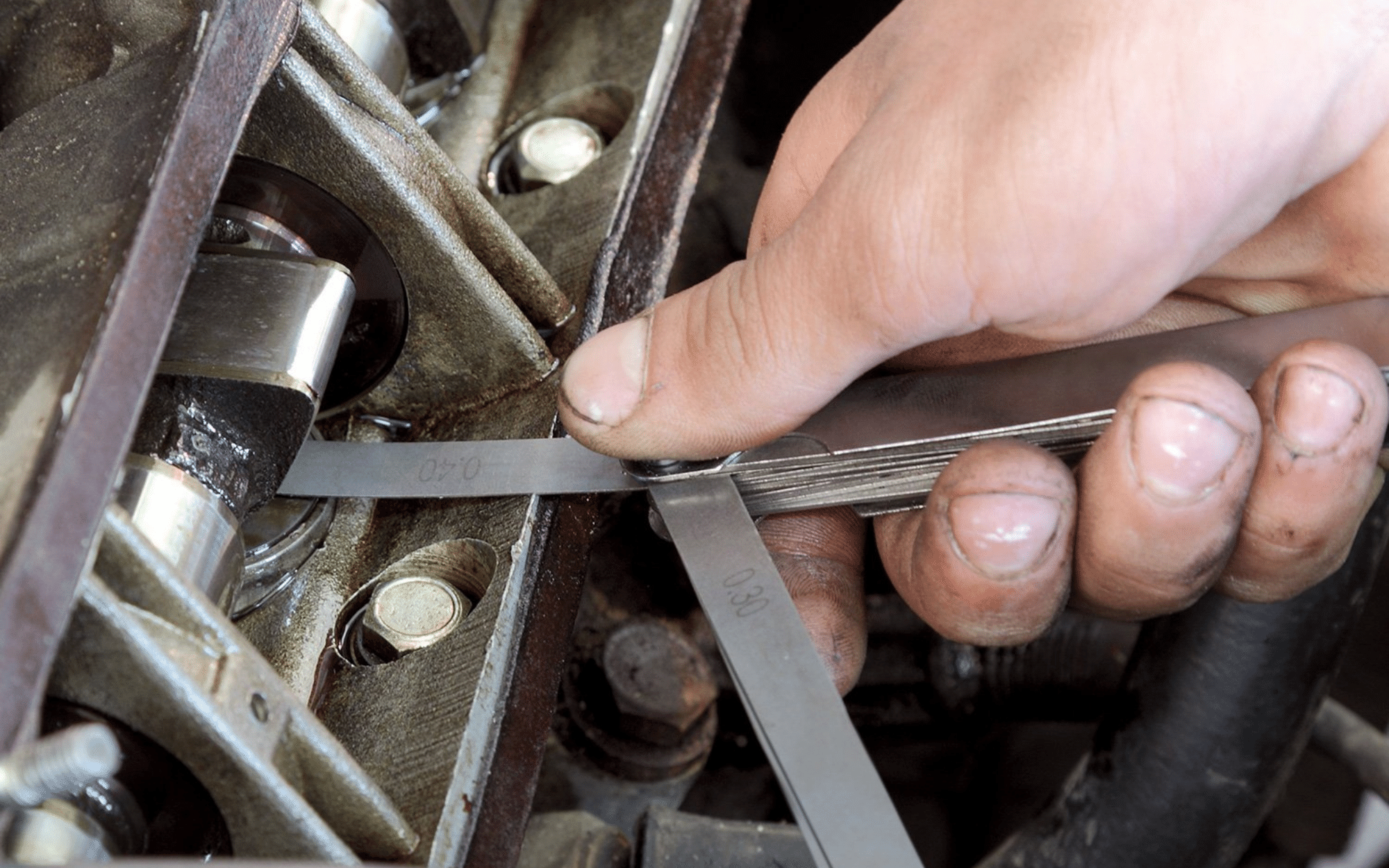

Selecting the right valve spring compressor requires evaluating several critical factors that directly impact tool performance and your working experience. It's essential to be able to measure and check valve spring tension and performance to ensure the tool is suitable for the job.

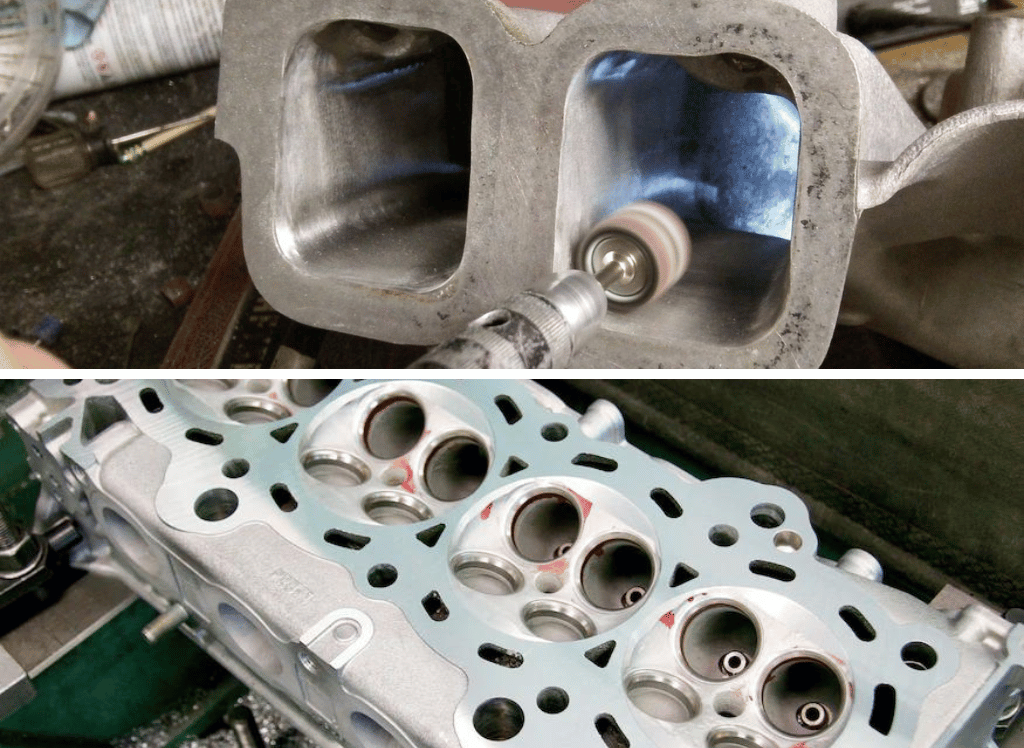

Compatibility with Engine Type

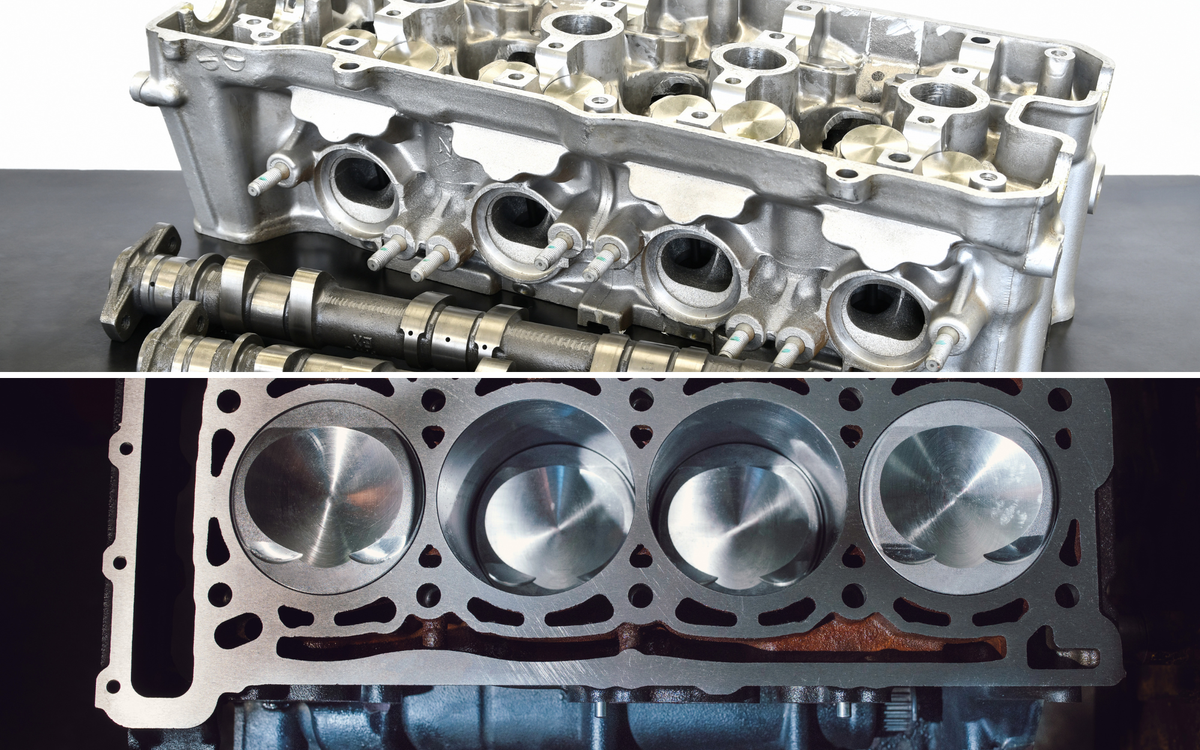

Engine compatibility represents the most crucial consideration when choosing a valve spring compressor. Different engines feature varying valve configurations, spring tensions, and access limitations. Overhead cam engines often require different approaches than pushrod designs, while modern multi-valve engines present unique challenges compared to traditional two-valve-per-cylinder arrangements.

Before purchasing any compressor tool, verify its compatibility with your specific engine applications. Review the manufacturer's specifications and compatibility charts to ensure a proper fit and function, so you won't have to worry about incompatibility.

Ease of Use and Ergonomics

Both professional mechanics and DIY enthusiasts benefit from tools that reduce physical strain during prolonged use. Look for compressors with comfortable grip surfaces, smooth operation, and intuitive adjustment mechanisms to make the job easier. Tools that require excessive force or awkward positioning can lead to fatigue and an increased risk of injury.

The best compressor tools provide sufficient mechanical advantage to compress even big, heavy-duty valve springs with reasonable effort. Smooth, precise operation enables better control during the compression and release processes, making challenging tasks more manageable.

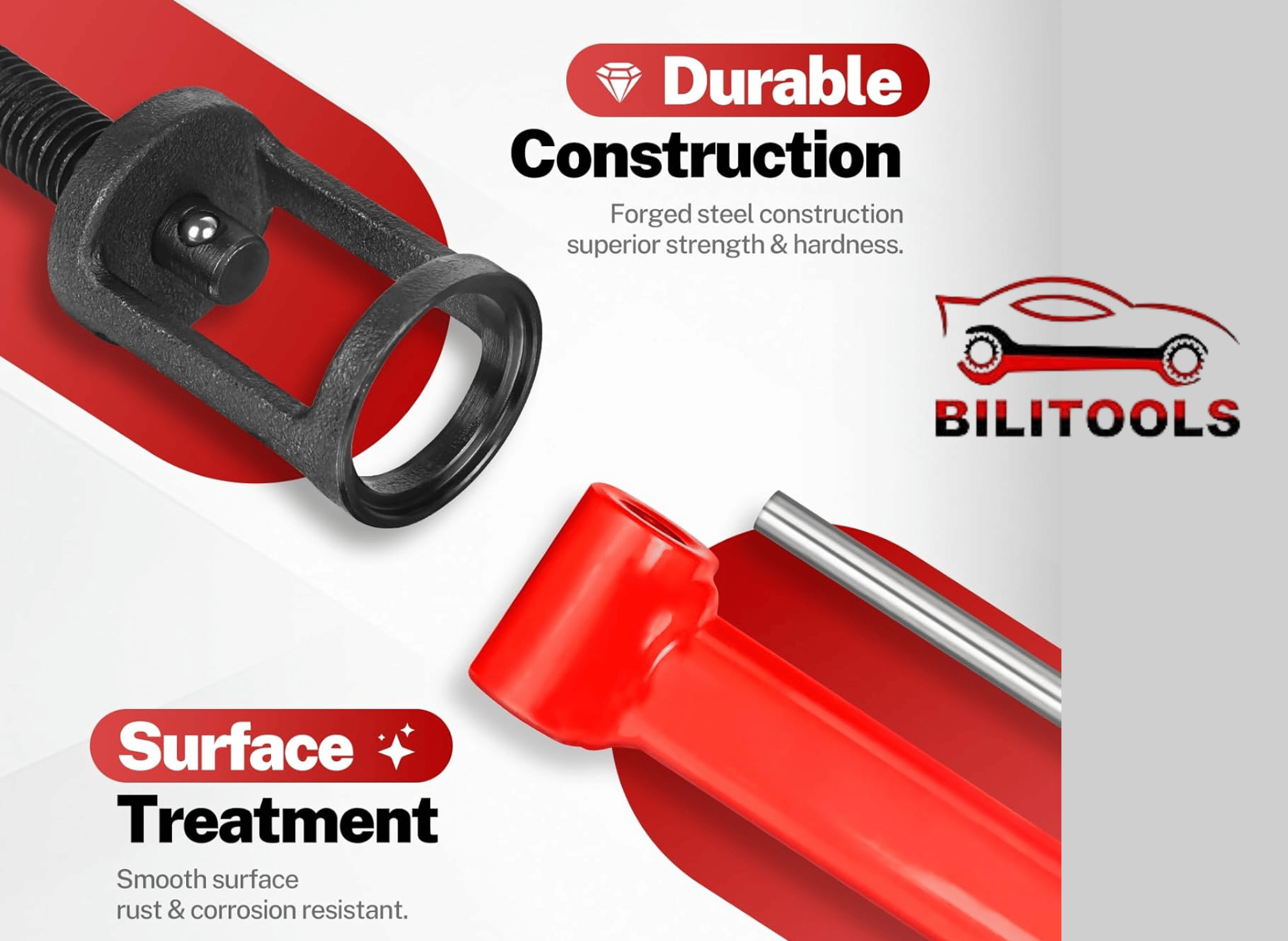

Build Quality and Durability

High-quality valve spring compressors are characterized by their robust construction, which utilizes hardened steel components. Look for tools with smooth, oxidized surfaces that resist rust and corrosion. Quality manufacturers often include protective cases or toolboxes to organize components and protect them during storage and transport.

Customer reviews provide valuable insights into long-term durability. The BILITOOLS kit, with its 4.6-star rating from 138 customers, demonstrates the importance of verified user feedback when evaluating tool quality. With a well-built tool, you won't have to worry about premature wear or tool failure.

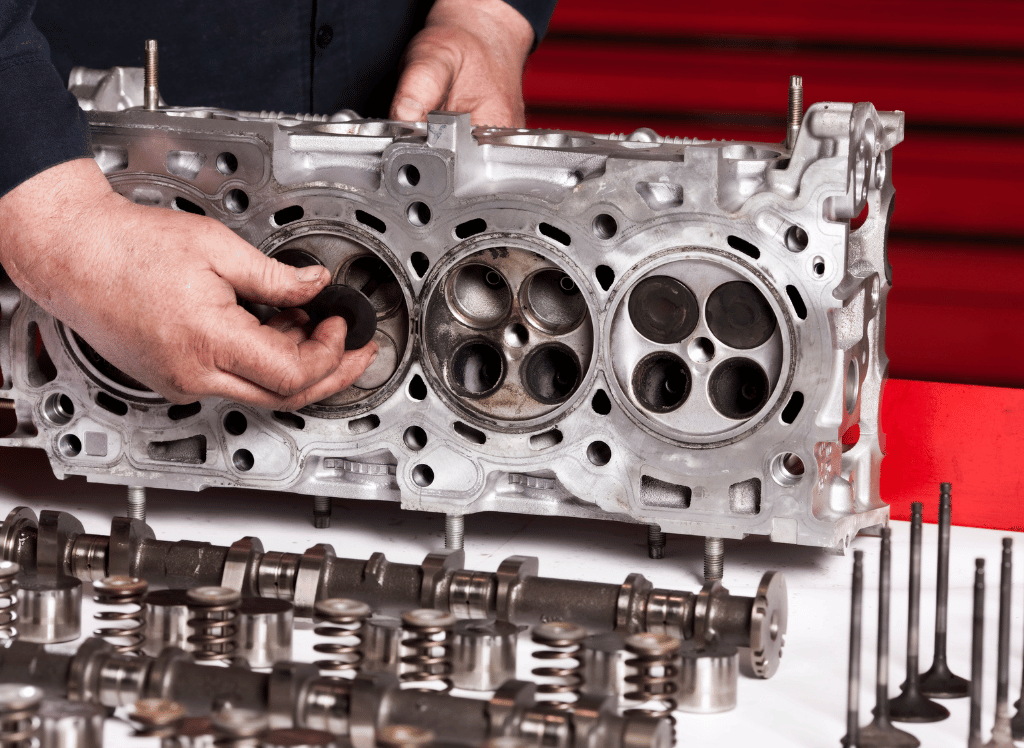

Step-by-Step Guide: Using a Valve Spring Compressor Tool

Proper technique ensures safe, efficient valve spring compression while protecting both the engine components and the tool itself.

Preparation and Safety Measures

Begin by ensuring the engine is completely cool and all fluids have been drained appropriately. Remove any components blocking access to the valve springs, including rocker arms, camshafts, or other valvetrain components as required by your specific engine design.

Inspect the valve spring compressor tool before use, checking for damaged or worn components. Ensure all adjustment mechanisms operate smoothly and that adapter pieces fit correctly on your valve configuration.

Wear appropriate safety equipment, including things like safety glasses and work gloves. Keep your workspace well-lit and organized to prevent tool misplacement during the procedure.

Step-by-Step Instructions

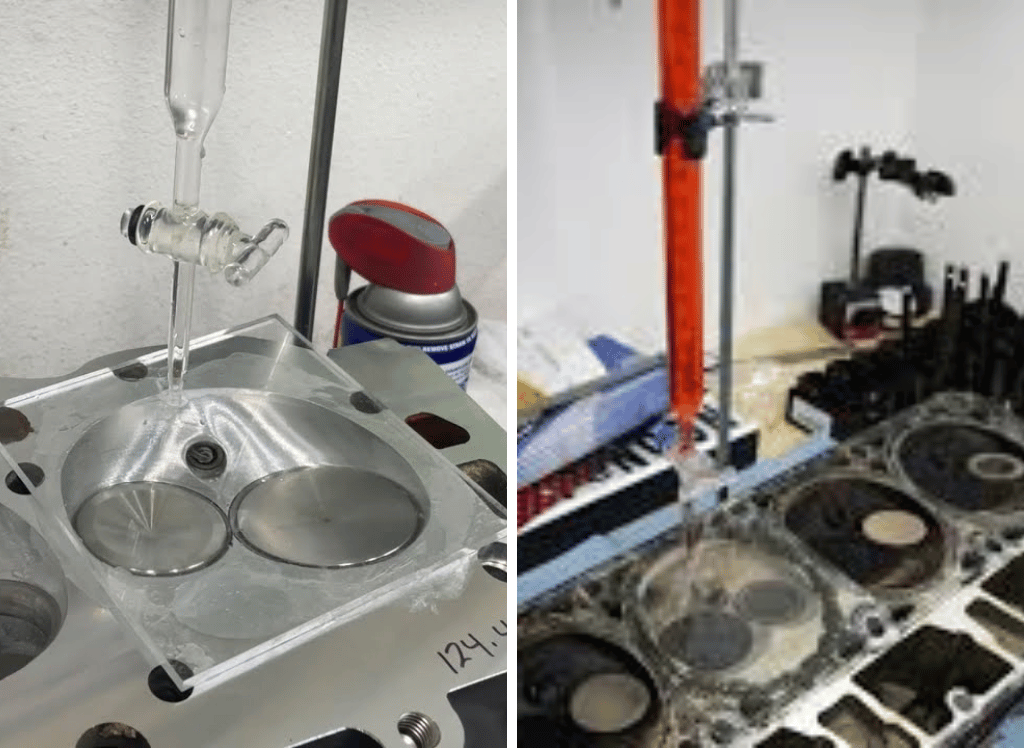

Position the compressor tool according to your specific engine configuration. For overhead valve compressors, ensure the tool's base contacts a solid surface while the compression mechanism aligns properly with the valve spring and retainer.

Gradually apply compression force, monitoring the valve spring's response. Most springs require steady, controlled pressure rather than sudden force. Watch for proper retainer alignment and ensure the valve stem remains centered during compression.

Once sufficient compression is achieved, carefully remove the valve spring retainers or keepers using appropriate tools. Maintain compression pressure throughout this process to prevent sudden spring release.

To release compression, gradually reduce pressure while supporting the valve spring. Carefully remove the compressor tool once all spring tension is relieved to ensure safety.

Tips and Tricks for Efficient Compression

Different valve springs require varying compression techniques. Heavy-duty springs may benefit from multiple compression cycles, gradually increasing pressure to reach full compression. This approach reduces tool stress and provides better control.

When working with multiple valves, establish a consistent pattern to prevent confusion and ensure all components are properly tracked. Label or organize removed parts to simplify reassembly.

Maintenance and Care

Proper maintenance extends tool life and ensures consistent performance over years of use, ultimately saving you time and effort.

Cleaning and Storage

Clean valve spring compressor tools thoroughly after each use, removing all oil, debris, and metal particles. Use appropriate solvents for stubborn deposits, saving time, but avoid harsh chemicals that might damage tool finishes.

Apply light oil to moving parts and adjustment mechanisms to prevent corrosion and ensure smooth operation. Always store tools in their original cases or in an organized toolbox to avoid damage and prevent component loss.

Inspection for Wear and Tear

Regularly inspect valve spring compressor tools for signs of wear, damage, or deformation. Pay particular attention to contact surfaces, adjustment threads, and leverage points where stress concentrates during use.

Replace worn or damaged components immediately to prevent tool failure during use. Most quality manufacturers offer replacement parts for their compressor tools, significantly extending the useful service life of these tools.

Choosing the Right Tool for Your Needs

Valve spring compressor tools represent essential equipment for anyone serious about vehicle engine maintenance and repair. The right tool makes valve service straightforward and safe, while the wrong choice can turn routine maintenance into a frustrating job, as well as other cylinder head repairs.

Consider your specific applications, budget constraints, and quality requirements when selecting a good compressor tool that meets your needs. Universal designs, such as the SMOTIVEPRO tool, offer versatility at a reasonable cost, while comprehensive kits, like the BILITOOLS set, provide specialized capabilities for demanding applications.

Regular maintenance of these precision tools ensures years of reliable service, making them worthwhile investments for both professional mechanics and dedicated enthusiasts. Quality valve spring compressor tools pay for themselves through improved efficiency, making tasks more manageable, reducing frustration, and enhancing safety during critical engine work. Continue to add one to your toolbox today.

Thank you for reading!

Your friend,

Todd

#BILITOOLS #ValveSpringCompressor #EngineTools #AutomotiveRepair #MechanicLife #GarageEssentials #CarMaintenance #DIYAuto #ToolSet #AutoTech

🧰🔧⚙️🛠️🚗🏁🧑🔧✅💪✨

Amazon Prime offers a wide range of products designed to cater to diverse customer needs, all with the added benefit of fast, reliable delivery. From household essentials and groceries to electronics, clothing, and entertainment, Prime members get access to exclusive deals and discounts across various categories.

Additionally, Prime membership includes access to services like Prime Video for streaming movies and TV shows, Amazon Music for ad-free music, and Prime Reading for eBooks and magazines. This comprehensive suite of benefits makes Amazon Prime a convenient and value-packed option for millions of customers worldwide.

- Prime for you, adult

- Free 30-day trial of Prime

- All of Prime, half the price.

- Prime Video

- Wedding Registry

- Kindle Unlimited

- Amazon Music,